2507 Duplex Stainless Steel Pipe Description

What makes 2507 unique is its unique composition, with an optimal balance of chromium and molybdenum. This carefully calibrated ratio ensures comprehensive protection against a range of corrosion types, including pitting, crevice and general corrosion. Whether exposed to harsh environments or corrosive chemicals, 2507 duplex stainless steel has good resilience, making it an ideal choice for applications where reliability is critical.

The superior mechanical properties of 2507 also add to its appeal. The material has high strength and excellent toughness, allowing it to withstand extreme conditions without compromising performance. Its ability to maintain structural integrity under pressure makes it a top choice for critical components in a variety of fields.

In addition to its impressive performance characteristics, 2507 Duplex Stainless Steel was designed with sustainability in mind. Its long service life and high corrosion resistance reduce the need for frequent replacement, ultimately reducing maintenance costs and environmental impact.

Product Parameters

| Product Name | 2507 Duplex Stainless Steel Pipe | |

| Type | Steel Pipe | |

| Outer diameter | Round Tube | 4mm-200mm |

| Square Tube | 10*10mm-100*100mm | |

| Rectangular Tube | 10*20mm-50*100mm | |

| Wall Thickness | 0.6mm-6.0mm | |

| Length | 1-6 meters, Length can be customized | |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

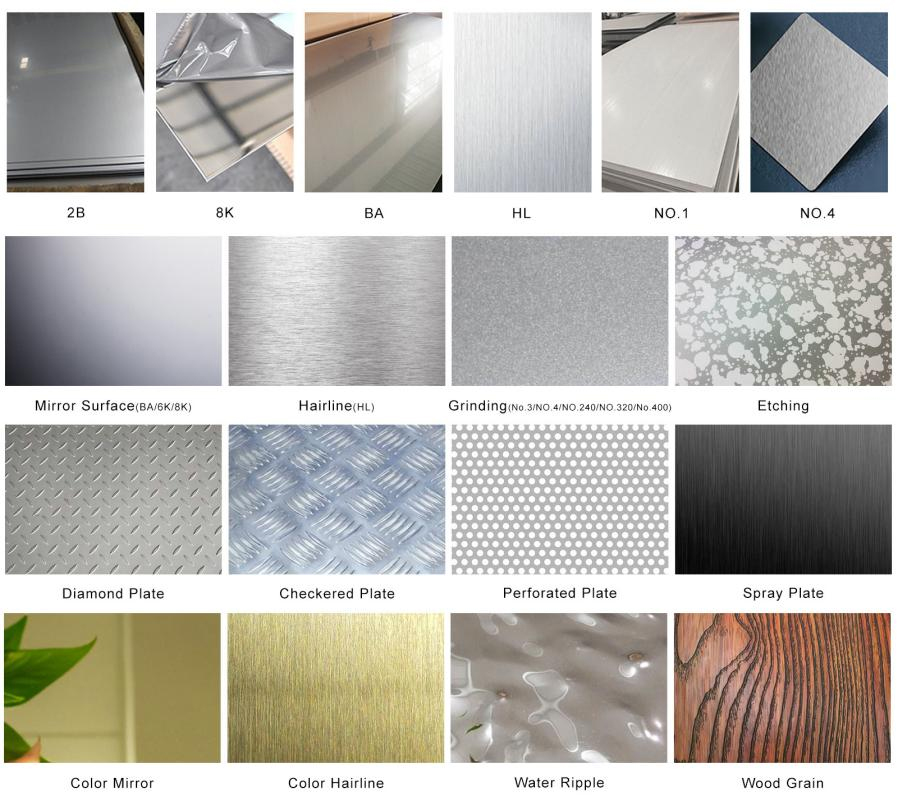

| Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. | |

| Scope of Application |

Common applications for stainless steel pipes include food processing,

Textile operations, Breweries, Water treatment plants, Oil and gas processing,

Fertilizers and pesticides, Chemical applications, Construction, Pharmaceuticals, Auto parts, etc.

|

|

| Certificate | ISO, SGS, BV, etc. | |

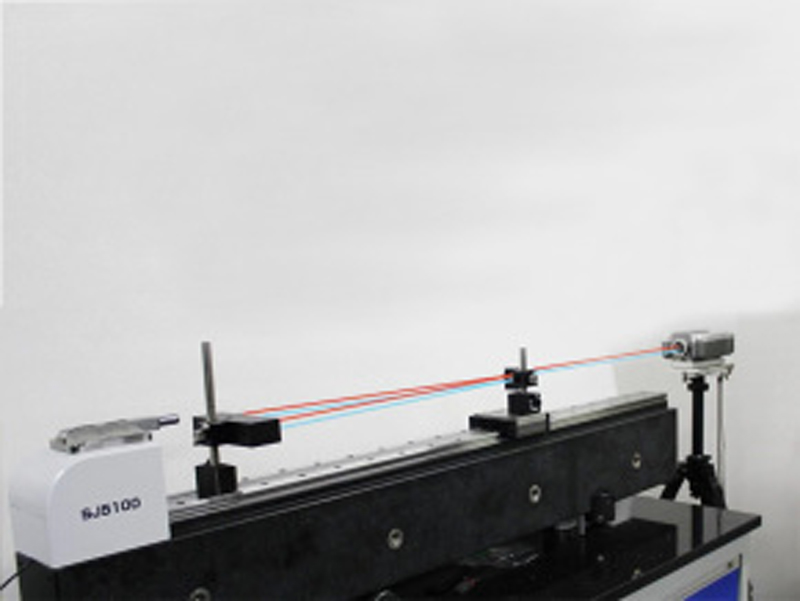

| Production Technology | Hot Rolling, Cold Rolling | |

| Edge Processing | Edging, Trimming | |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.03 | ≤0.8 | ≤1.2 | 24.0~26.0 | 6.0~8.0 | ≤ 0.02 | ≤ 0.035 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥795 | ≥550 | ≥15 | ≤ 310HB |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 7.75 | 200 | 13.0 | 17.0 | 80 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

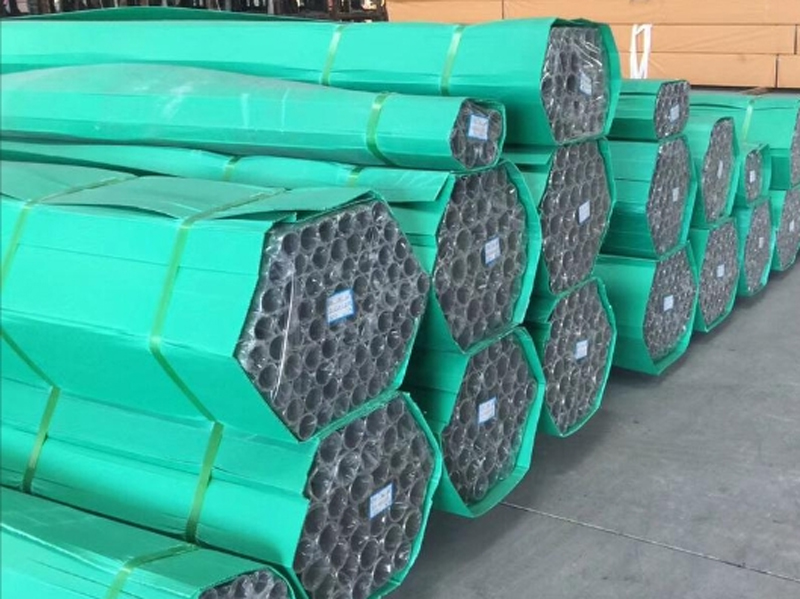

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners