316Ti Stainless Steel Pipe Description

316Ti has been engineered to provide excellent resistance to general corrosion, making it an ideal choice for environments that require exceptional resilience. Unlike traditional chrome-nickel austenitic stainless steels such as 304, 316Ti excels in resistance to pitting and crevice corrosion, ensuring your application is protected even in the harshest conditions. This makes it particularly suitable for marine, chemical processing and other industries where exposure to corrosive elements is a concern.

The addition of titanium to 316Ti enhances its stability at high temperatures, allowing it to maintain its mechanical properties and resist sensitization during welding. This means you can rely on 316Ti to maintain its structural integrity and longevity, reducing the need for frequent replacement and maintenance.

Product Parameters

| Product Name | 316Ti Stainless Steel Pipe | |

| Type | Steel Pipe | |

| Outer diameter | Round Tube | 4mm-200mm |

| Square Tube | 10*10mm-100*100mm | |

| Rectangular Tube | 10*20mm-50*100mm | |

| Wall Thickness | 0.6mm-6.0mm | |

| Length | 1-6 meters, Length can be customized | |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

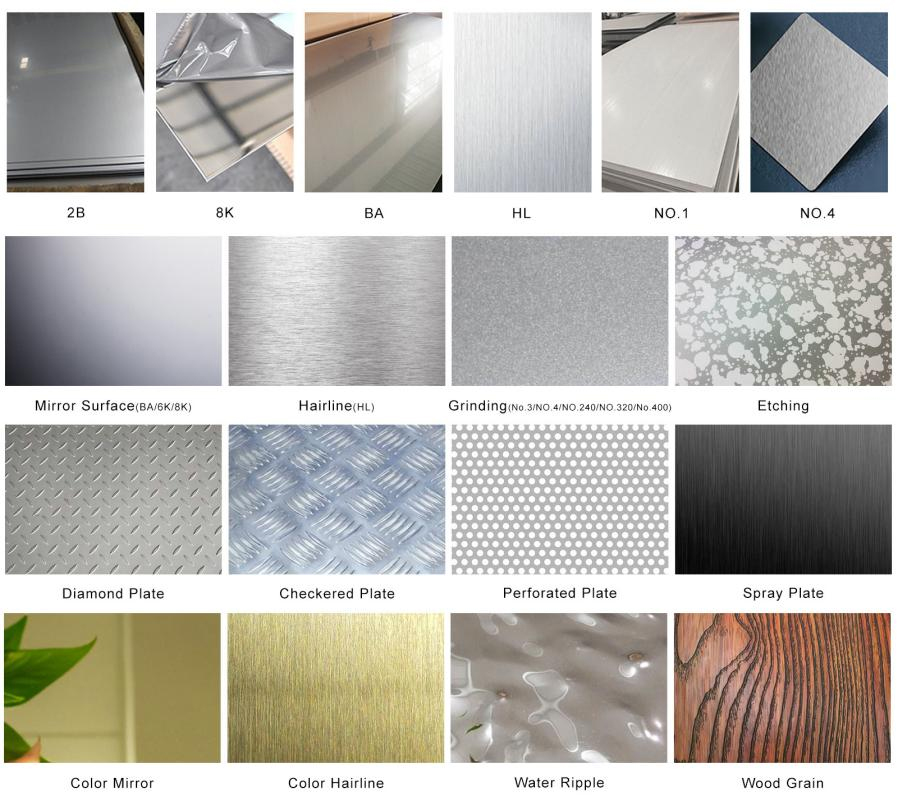

| Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. | |

| Scope of Application |

Common applications for stainless steel pipes include food processing,

Textile operations, Breweries, Water treatment plants, Oil and gas processing,

Fertilizers and pesticides, Chemical applications, Construction, Pharmaceuticals, Auto parts, etc.

|

|

| Certificate | ISO, SGS, BV, etc. | |

| Production Technology | Hot Rolling, Cold Rolling | |

| Edge Processing | Edging, Trimming | |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.08 | ≤1.0 | ≤2.0 | 16.0~18.0 | 10.0~14.0 | ≤ 0.03 | ≤ 0.045 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥515 | ≥205 | ≥40 | ≤ 187HB;≤ 90HRB;≤ 200HV |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 7.99 | 193 | 16.0 | 16.2 | 74 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

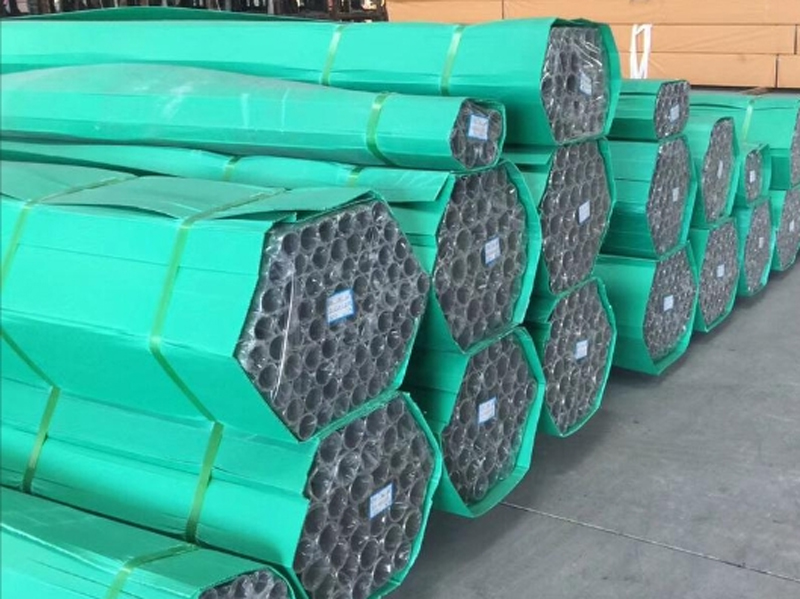

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners