316 Stainless Steel Plate Description

316 stainless steel is widely favored in the stainless industry for several key reasons. Grade 316 is the standard molybdenum-bearing austenitic grade, renowned for its high resistance to pitting and crevice corrosion in chloride environments. As a result, 316 stainless steel is commonly employed in applications where superior corrosion resistance is essential. For instance, in marine engineering, 316 stainless steel is frequently utilized for manufacturing ship parts, subsea pipelines, offshore platforms, and other marine facilities. In the chemical industry, it is a common choice for producing equipment such as storage tanks, reactors, and pipelines. Moreover, in the medical field, 316 stainless steel is widely used for manufacturing medical devices and implants due to its exceptional biocompatibility and corrosion resistance.

Product Parameters

| Product Name | 316 Stainless Steel Plate |

| Type | Plate |

| Thickness | 0.3mm-200mm |

| Length | 2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. |

| Width | 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

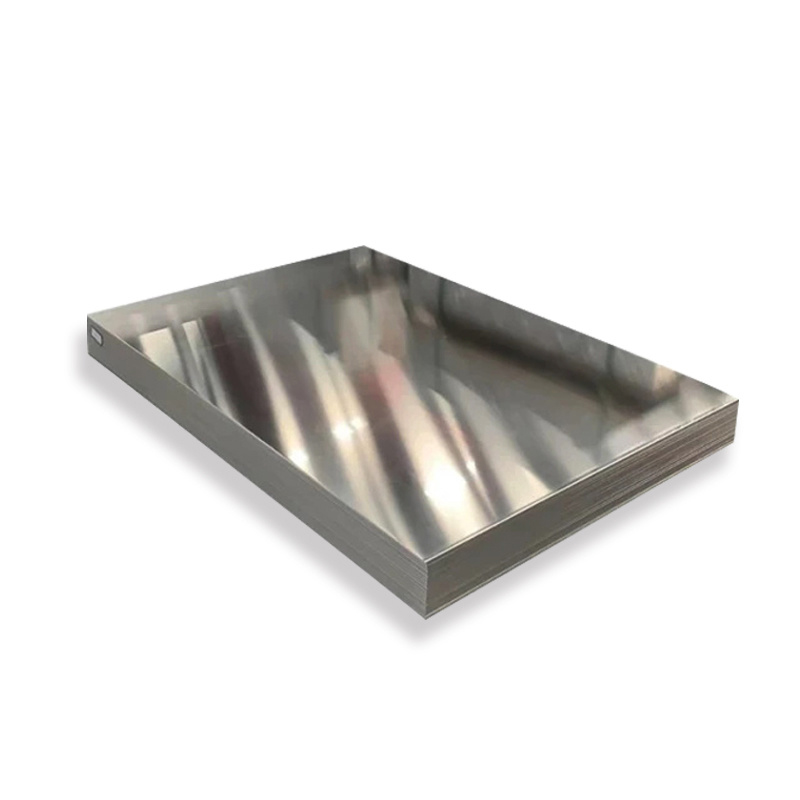

| Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

| Scope of Application | Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

| Certificate | ISO, SGS, BV, etc. |

| Production Technology | Hot Rolling, Cold Rolling |

| Edge Processing | Edging, Trimming |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P | Mo |

| ≤ 0.03 | ≤ 0.75 | ≤ 2.0 | 16.0~18.0 | 10.0~14.0 | ≤ 0.03 | ≤ 0.045 | 2.0~3.0 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥480 | ≥177 | ≥ 40 | ≤ 187HB;≤ 90HRB;≤ 200HV |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 7.99 | 193 | 16.0 | 16.2 | 74 |

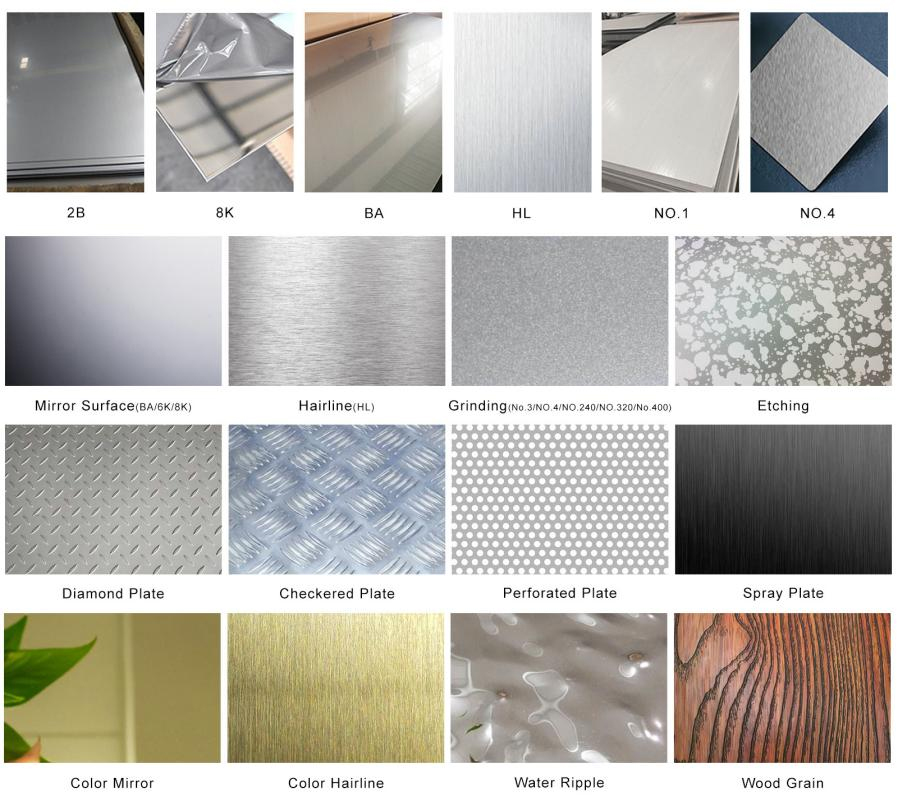

Surface Selection

| Name | Surface | Features | Use |

| Original Surface | NO.1 | Silver white | Industrial tanks, chemical industry equipment, etc., thicker by the mm-10.0mm of 3.0. Uses that do not require a surface gloss |

| Matte | |||

| Nlunt Surface | 2D | Slightly shiny silvery white | Used for deep drawing processing, such as automobile components, water pipes, etc. General materials, deep drawing materials |

| Fog Surface | 2B | Silver white with better gloss and flatness than 2D surface 0.39 micron roughness | Such as tableware, building materials, etc. After surface treatment to improve mechanical properties, almost all applications are satisfied. |

| Frosted Surface | NO.3 | Has a good gloss, with discontinuous rough | Used for building interior and exterior decoration materials, electrical products and kitchen equipment. |

| Frosted Surface | NO.4 | Has a better gloss, with discontinuous rough, stripes than NO. 3 fine | Used for baths, building interior and exterior decoration materials, electrical products, kitchen equipment and food equipment. |

| Frosted Surface | NO.240 | Has a better gloss, with discontinuous rough, stripes than NO. 4 fine | Used for bathroom, building interior and exterior decoration materials, electrical products, kitchen equipment and food equipment. |

| Frosted Surface | NO.320 | Has a good gloss, with discontinuous rough | Building Materials, Kitchenware |

| Frosted Surface | NO.400 | Has a good gloss, with discontinuous rough | Building materials, kitchen utensils, food equipment, etc. |

| Brushed Surface | HL | Silver gray with hairline stripes on the 2D or 2B product with the appropriate particle size abrasive material polished to make the surface continuous grinding pattern | Mainly used in architectural decoration, elevators, building doors, panels, etc. |

| Bright Surface | BA | Excellent surface gloss with high reflectivity | Used for home appliances, mirrors, kitchen equipment, decorative materials, etc. |

| Mirror | 6K | Not much worse than a mirror. | Mirror, trim panel |

| Mirror | 8K | Like a mirror. | Mirror, trim panel |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners