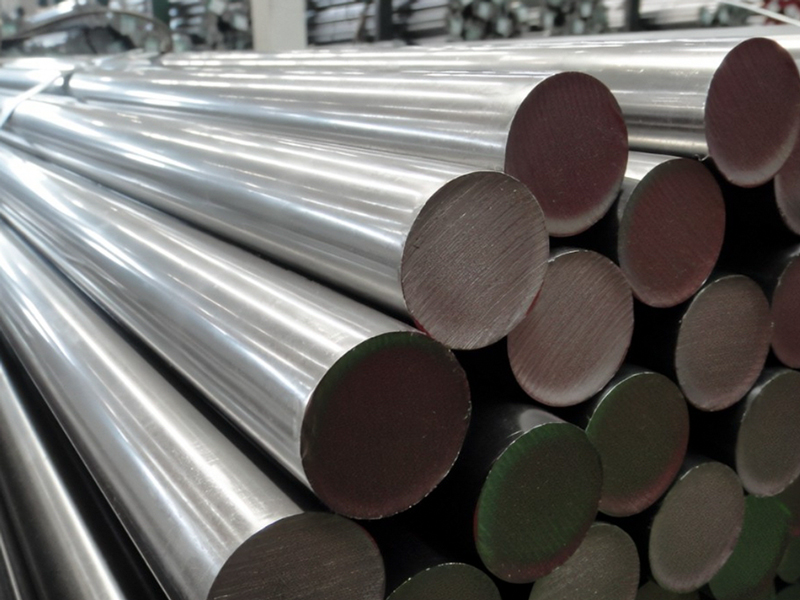

316L Stainless Steel Bar Description

316L stainless steel bar, distinguished by its lower carbon content compared to 316 stainless steel bar, is primarily utilized for welding purposes. The reduced carbon content significantly minimizes the precipitation of carbides in the heat-affected zone near the weld, thereby mitigating the risk of intergranular corrosion in certain environments. Notably, there is no need to anneal weld joints before using the completed metal form, which contributes to time and effort savings. Similar to 304, 316L stainless steel bar is widely employed and offers superior corrosion resistance. Additionally, it boasts high temperature resistance of up to 1000 degrees and exhibits stronger rust resistance compared to 200 series stainless steel materials.

Product Parameters

| Product Name | 316L Stainless Steel Bar | |

| Type | Steel Bar | |

| Outer Diameter | Round Bar | 4mm-500mm |

| Hexagon Bar | 18mm-57mm (11/16″ to 2-3/4″) | |

| Square Bar | 18mm-47mm (11/16″ to 1-3/4″) | |

| Flat Steel | 1/2 "to 10", Thickness: 2mm-150mm, Can provide customized | |

| Length | 1-6 meters, Length can be customized | |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

| Surface | Black, Bright Polished, Rough Turning, Mattness Surface Treatment, No. 4. BA, etc. | |

| Scope of Application | Stainless steel bars find extensive applications across diverse industries, including shipbuilding, defense, automotive, textiles, paper and pulp, manufacturing, cement, heavy earthmoving equipment, and construction. | |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P | Mo |

| ≤ 0.03 | ≤1.0 | ≤ 2.0 | 16.0~18.0 | 10.0~14.0 | ≤ 0.03 | ≤ 0.045 | 2.0~3.0 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥480 | ≥177 | ≥ 40 | ≤ 187HB;≤ 90HRB;≤ 200HV |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 7.99 | 193 | 16.0 | 16.2 | 74 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners