4135/4140/4142/6150 Alloy Plate EN10083-3

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

4135/4140/4142/6150 Alloy Plate EN10083-3

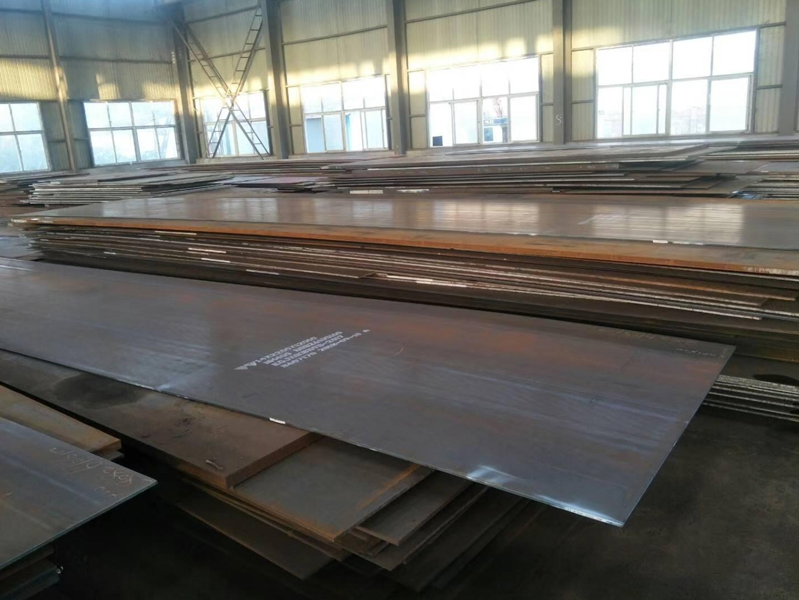

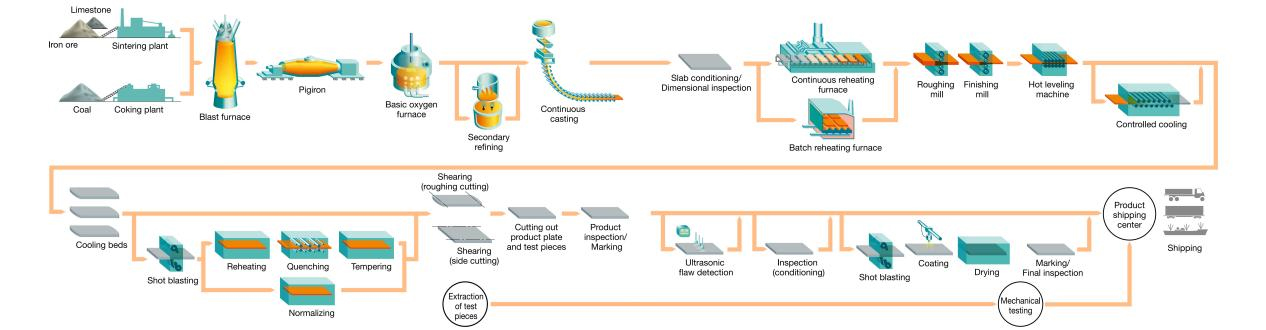

EN 10083-3:2006 steel is an alloy steel designed for quenching and tempering processes. This standard governs the technical delivery conditions of alloy steels, including grades such as 50CrMo4, 51CrV4, 20MnB5, 34CrMo4, 42CrMo4, and 27MnCrB5-2. EN 10083-3 steel plates exhibit high strength, exceptional toughness, and good hardenability. The alloy necessitates high-temperature preheating before welding to alleviate stress post-welding.

Product Parameters

| Product Name | 4135/4140/4142/6150 Alloy Plate EN10083-3 |

| Type | Hot Rolling, Cold Rolling |

| Thickness | 0.1mm-400mm |

| Length | 1m-12m, or Customized Size |

| Width | 100mm-3000mm |

| Standard | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

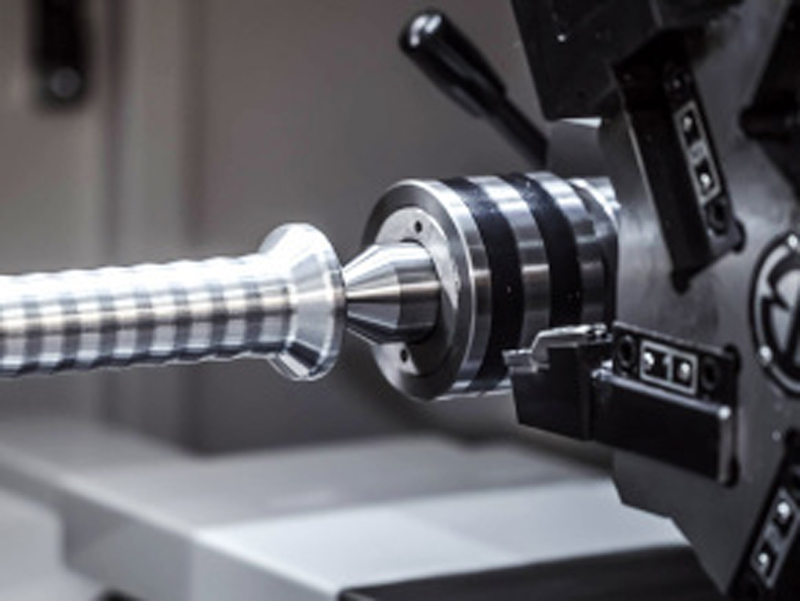

| Scope of Application | EN 10083-3 steel plates are utilized in the production of tools that demand excellent plasticity and high strength. They are commonly chosen for manufacturing large and critical components, including heavy mechanical shafts, turbine shaft blades, high-load transmission parts, fasteners, crankshafts, gears, and robust motor structures. |

| Certificate | ISO, SGS, BV, etc. |

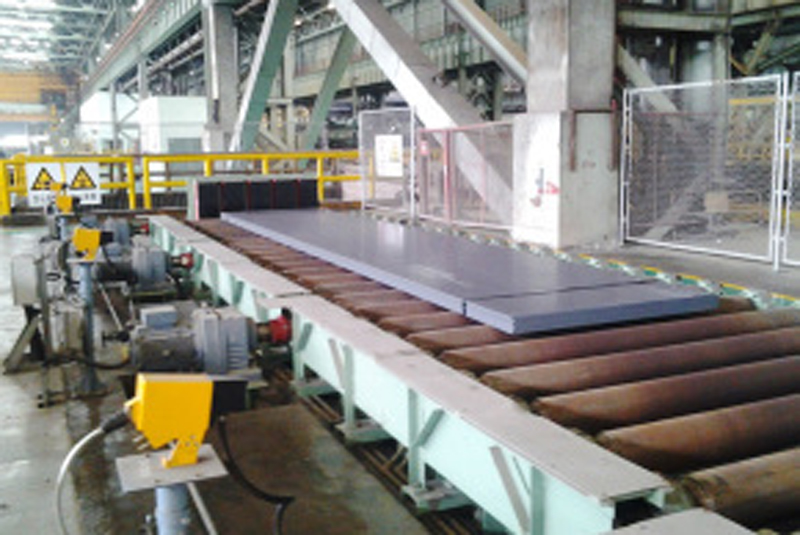

| Production Technology | Rolling, Annealing, Quenching, Tempered or Standard |

| Edge Processing | Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

| Brand | C | Si max | Mn | P max | S max | Cr | Mo | V |

| 34CrMo4 | 0.3-0.37 | 0.40 | 0.6-0.9 | 0.025 | 0.035 | 0.9-1.2 | 0.15-0.3 | - |

| 42CrMo4 | 0.38-0.45 | 0.40 | 0.6-0.9 | 0.025 | 0.035 | 0.9-1.2 | 0.15-0.3 | - |

| 50CrMo4 | 0.46-0.54 | 0.40 | 0.5-0.8 | 0.025 | 0.035 | 0.9-1.2 | 0.15-0.3 | - |

| 51CrV4 | 0.47-0.55 | 0.40 | 0.7-1.1 | 0.025 | 0.025 | 0.9-1.2 | - | 0.1-0.25 |

Mechanical Properties

| Thickness | Re min. N/mm2 | Rm N/mm2 | A min% | From min% |

| ≤8mm | 900 | 1000-1300 | 10 | 40 |

| 8mm-20mm | 750 | 1000-1200 | 11 | 45 |

| 20mm-60mm | 650 | 900-1100 | 12 | 50 |

| 60mm-100mm | 550 | 800-950 | 13 | 50 |

| 100mm-160mm | 500 | 750-900 | 14 | 55 |

Equivalent Material

| European Standard | American Standard | German Standard | Japanese standard | National Standard | International Standards |

| 34CrMo4 | 4135 | 34CrMo4 | SCM435H | 35CrMo | 34CrMo4 |

| 42CrMo4 | 4140, 4142 | 42CrMo4 | SCM440H | 42CrMo | 42CrMo4 |

| 50CrMo4 | - | 50CrMo4 | - | 50CrMo | 50CrMo4 |

| 51CrV4 | 6150 | 50CrV4 | SUP10 | 50CrVA | 51CrV4 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners