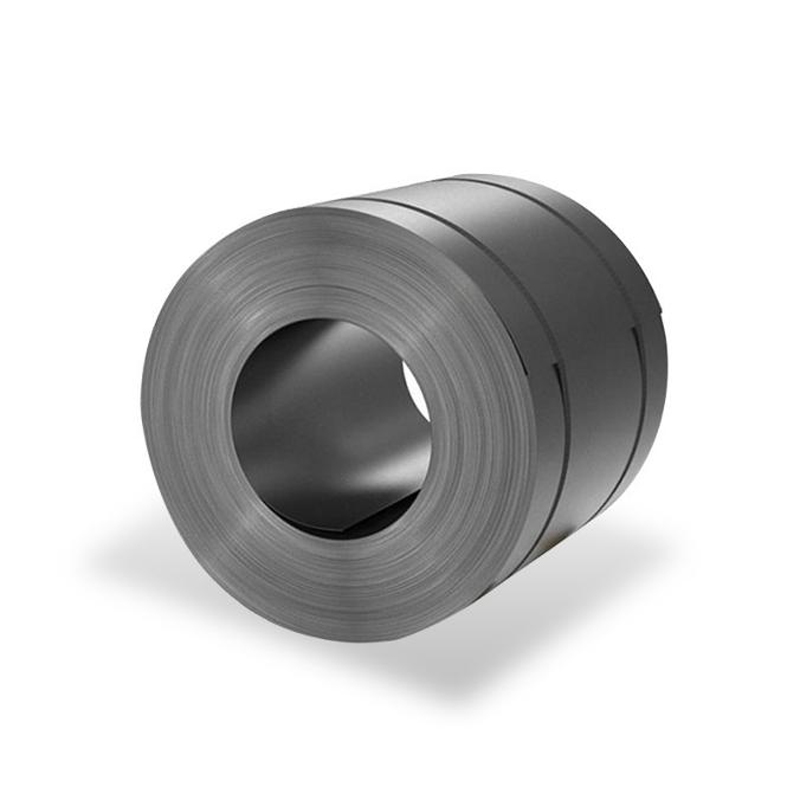

A533 Pressure Vessel Carbon Steel Coil

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

A533 Pressure Vessel Carbon Steel Coil description

A533 pressure vessel steel coils are typically subjected to quenching and tempering heat treatment, and are available in five different strength grades: Class A, Class B, Class C, Class D, and Class E. These ASTM A533 pressure vessel steel coils exhibit exceptional low-temperature impact toughness and mechanical properties, making them well-suited for use in low-temperature conditions. Widely employed in low-temperature separation processing and liquefied gas storage, these coils are commonly utilized in applications such as large-scale vacuum low-temperature liquefied natural gas (LNG) storage equipment. Additionally, they are frequently utilized in the strip area of nuclear reactor vessels, where material properties may be influenced by intense radiation.

Product Parameters

| Product Name | A533 Pressure Vessel Carbon Steel Coil |

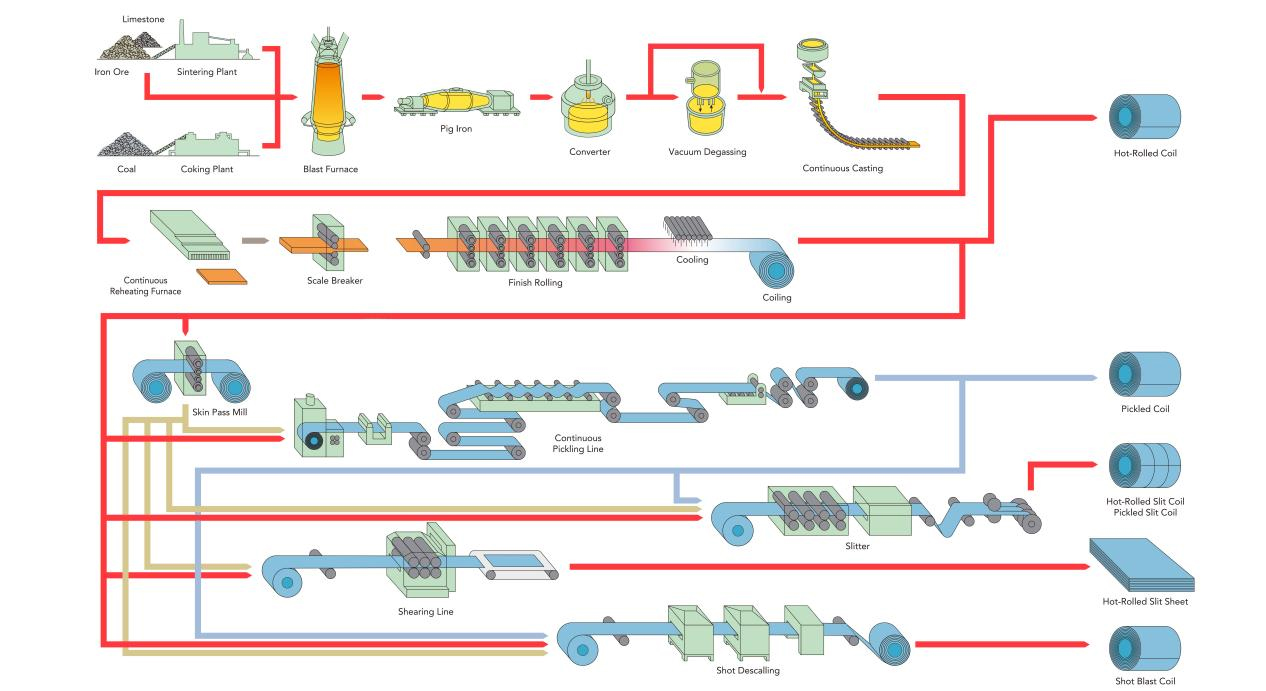

| Production Process | Hot Rolling, Cold Rolling |

| Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

| Width | 45mm-2200mm |

| Length | Custom Size |

| Thickness | Hot Rolling: 2.75mm-100mm Cold Rolling: 0.2mm-3mm |

| Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

| Surface Process | Ordinary, Wire Drawing, Laminated Film |

| Scope of Application | ASTM A533 boiler vessel plates exhibit outstanding low-temperature impact toughness and mechanical properties, making them well-suited for use in low-temperature conditions. These plates are widely employed in low-temperature separation processing, liquefied gas storage, and other applications, including large-scale vacuum low-temperature liquefied natural gas (LNG) storage equipment. |

Chemical Composition

| A533 | Class A | Class B | Class C | Class D | Class E | |

| C | 0.25 | 0.25 | 0.25 | 0.25 | 0.20 | |

| Mn | Smelting Analysis | 1.15~1.50 | 1.15~1.50 | 1.15~1.50 | 1.15~1.50 | 1.15~1.70 |

| Finished Product Analysis | 1.07~1.62 | 1.07~1.62 | 1.07~1.62 | 1.07~1.62 | 1.04~1.84 | |

| P | 0.025 | 0.025 | 0.025 | 0.025 | 0.020 | |

| S | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | |

| Si | Smelting Analysis | 0.15~0.40 | 0.15~0.40 | 0.15~0.40 | 0.15~0.40 | 0.15~0.40 |

| Finished Product Analysis | 0.13~0.45 | 0.13~0.45 | 0.13~0.45 | 0.13~0.45 | 0.13~0.45 | |

| Mo | Smelting Analysis | 0.45~0.60 | 0.45~0.60 | 0.45~0.60 | 0.45~0.60 | 0.25~0.60 |

| Finished Product Analysis | 0.41~0.64 | 0.41~0.64 | 0.41~0.64 | 0.41~0.64 | 0.21~0.64 | |

| Ni | Smelting Analysis | … | 0.40~0.70 | 0.70~1.00 | 0.20~0.40 | 0.60~1.00 |

| Finished Product Analysis | … | 0.37~0.73 | 0.67~1.03 | 0.17~0.43 | 0.57~1.03 | |

| Cr | Smelting Analysis | … | … | … | … | 0.60 |

| Finished Product Analysis | … | … | … | … | 0.64 |

Mechanical Properties

| A572 | Yield Strength(Ksi) | Tensile Strength(Ksi) | Elongation% 8inches |

| Grade42 | 42 | 60 | 20 |

| Grade50 | 50 | 65 | 18 |

| Grade60 | 60 | 75 | 16 |

| Grade65 | 65 | 80 | 15 |

Physical Performance

| Physical Performance | Metric | Imperial |

| Density | 7.7-8.03 g/cm3 | 0.278-0.290 lb/in3 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners