Bright Steel Bar Description

Our bright steel bars are engineered to deliver exceptional dimensional precision and accuracy, making them ideal for the production of critical components such as gears, shafts and bearings. Whether you are in the automotive, aerospace or manufacturing industries, our steel bars meet the rigorous demands of modern engineering.We produce our bright steel rods using a cold-drawn process, which produces a product that is not only strong and durable, but also has excellent mechanical properties. This means you can rely on our steel rods to withstand the rigors of demanding applications while maintaining their structural integrity. The polished surface not only increases the durability of the steel rods, but also reduces friction, making them suitable for high-speed applications.In addition to its outstanding performance characteristics, our bright steel rods are also available in a variety of sizes and lengths, allowing you to select the rod that best suits your specific project requirements. We understand that precision is of the utmost importance in engineering, and our steel rods are manufactured to the highest standards to ensure that you receive a product that meets your exact specifications.

Product Parameters

| Product Name | Bright Steel Bar | |||

| Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. | |||

| Common Round Bar Specifications | 3.0-50.8 mm, Over 50.8-300mm | |||

| Flat Steel Common Specifications | 6.35x12.7mm, 6.35x25.4mm, 12.7x25.4mm | |||

| Hexagon Bar Common Specifications | AF5.8mm-17mm | |||

| Square Bar Common Specifications | AF2mm-14mm, AF6.35mm, 9.5mm, 12.7mm, 15.98mm, 19.0mm, 25.4mm | |||

| Length | 1-6meters, Size Accept Custom | |||

| Diameter(mm) | Hot Rolling Round Bar | 25-600 | Cold Rolling Square Bar | 6-50.8 |

| Hot Rolling Square Bar | 21-54 | Cold Rolling Hexagon Bar | 9.5-65 | |

| Cold Rolling Round bar | 6-101.6 | Forged Rebar | 200-1000 | |

| Surface Process | Bright, Polished, Black | |||

| Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |||

What are the types of bright bars?

Bright Round Bars:

A bright round bar is designed through extensive heat treatment to provide extreme hardness. Its properties can be easily enhanced by adding other elements to the alloy.

The most commonly used round bar grades include 201, 202, 304, 309, 316, 316L, 316Ti, 321 and the 400 series.

Bright Rectangular Bars:

Rectangular bars are highly resistant to heat and external impacts, which makes them highly preferable for manufacturing small machining components.

Stainless steel rectangular bars are heat-treated, cold drawn, annealed and tempered before they are formed for machining.

A typical stainless steel rectangular bar ranges from 12mm-50mm in diameter.

Bright Hex Bars:

The hexagonal shape of hex bars is primarily meant for manufacturing small fasteners and threaded components such as nuts, valves, hose ends, fasteners, hex bolts, etc.

Hex bars are extensively used in all fastening applications due to their reliable strength and durability. They are also available in both 300 and 400 series grades.

The bright bar manufacturing process

Bright Bars are produced by using the process of cold drawing, centerless grinding, peeling, shaving, turning, or a combination of these processes. As a result, it has better dimensional accuracy, smooth surface, straightness and is usually free from surface defects.

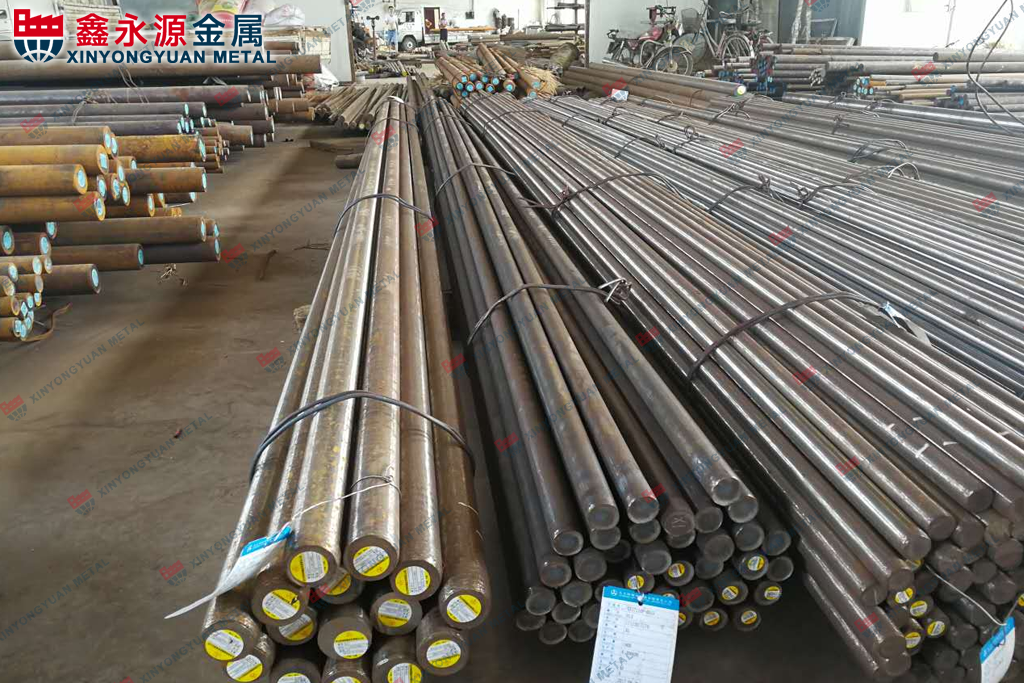

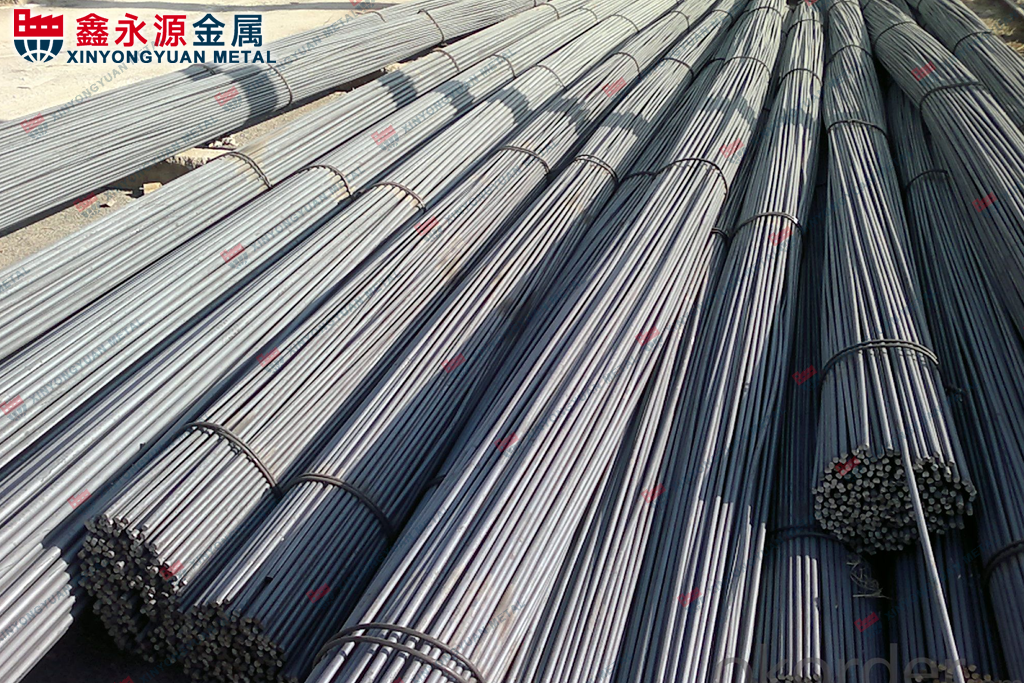

Raw Material

The raw material is made into a hot-rolled steel bar. Because the high temperatures extrude the hot-rolled products, they generally acquire a rough and scaled surface property and may show the difference in shape and size.

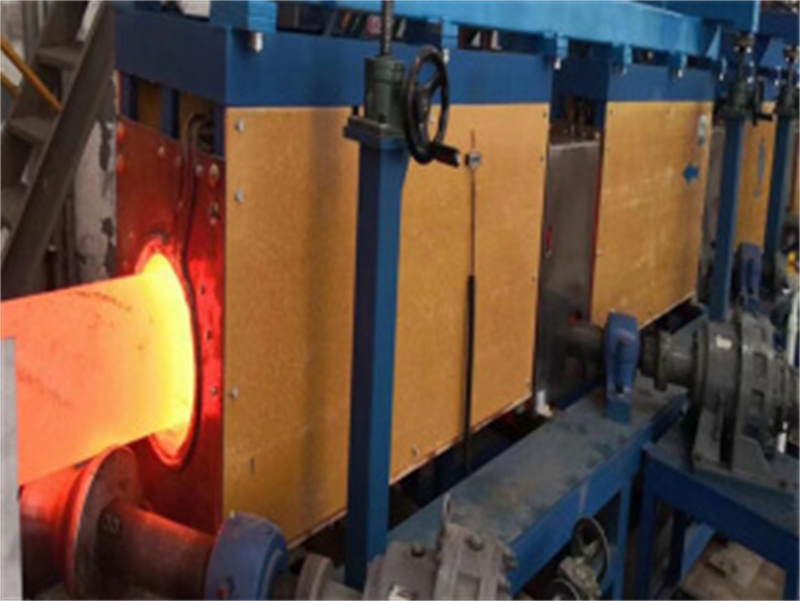

Drawing

The material is brought to room temperature during this process. One end of the bars goes to the gripping device of the drawing machine. The drawing machine pulls the bar through the die. The die cause reduction in the diameter of the original bar, which eventually increases the length of the bars.

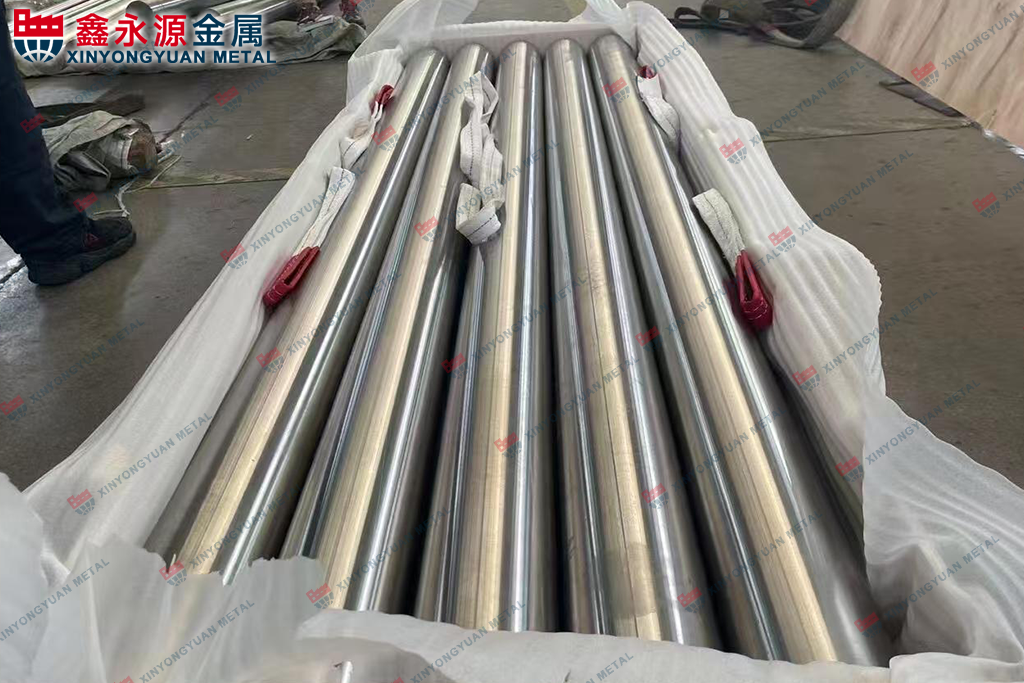

Finished Product

The bright bar’s finished product creates a perfect polished finish. This process increases mechanical properties, helps improve machining characteristics, and presents precise & uniform diameter tolerances.

Scope of Application

Bright bars are a prime component for manufacturing in various industries such as:

● Engineering and construction to provide prompt stability, strength and durability to giant structures.

● In the automobile industry for designing frames and chassis

● For designing railings, trellis and fences in societies and public places

● For manufacturing of machine components in various shapes and sizes

● For making micro-size to mega-size fastener products for all industrial and non-industrial applications.

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners