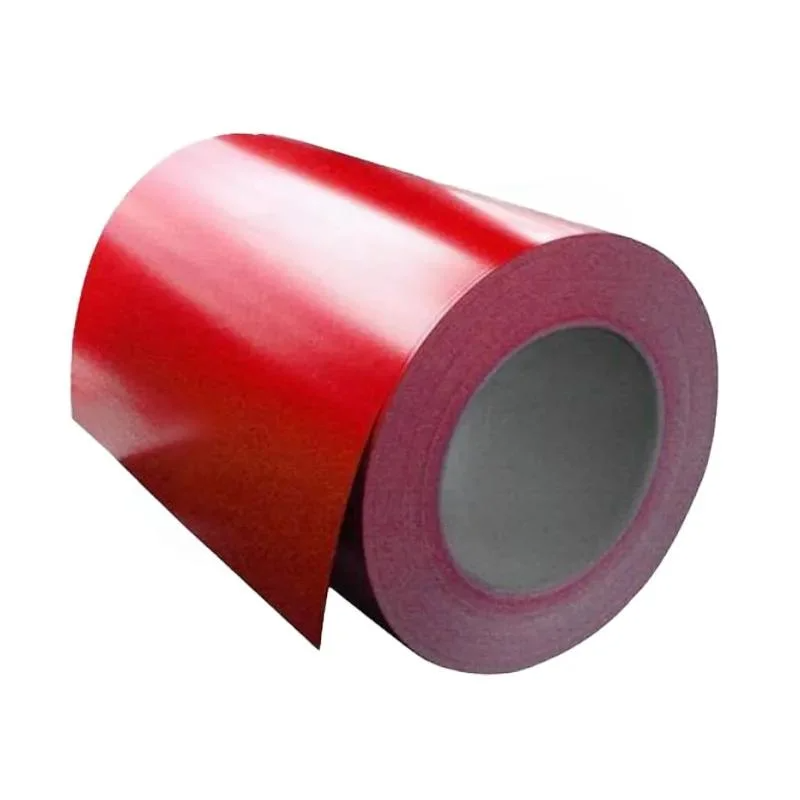

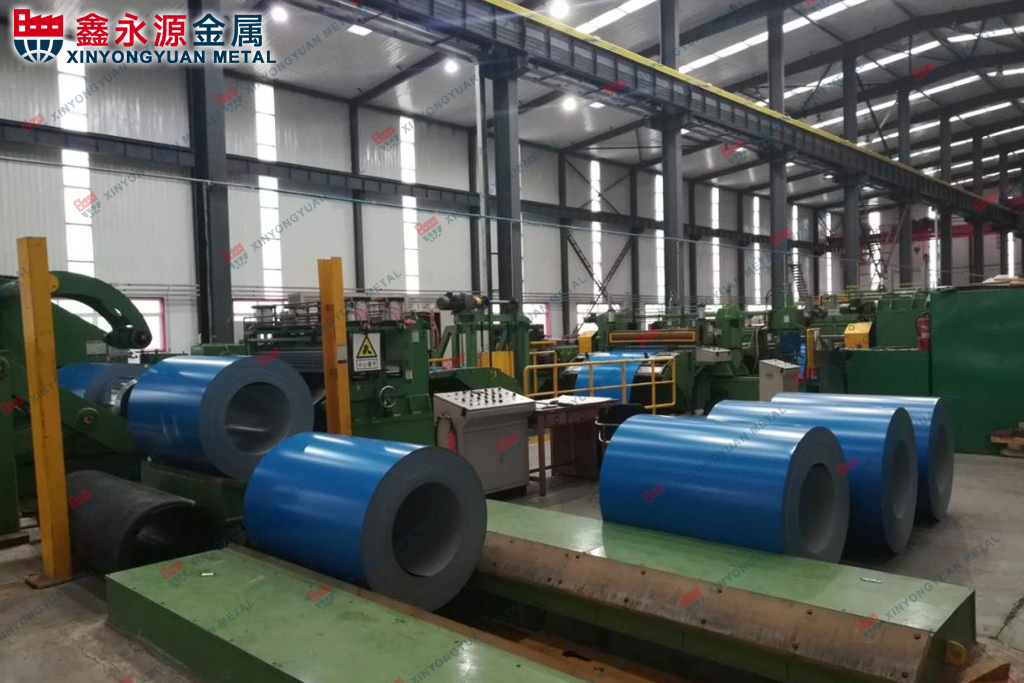

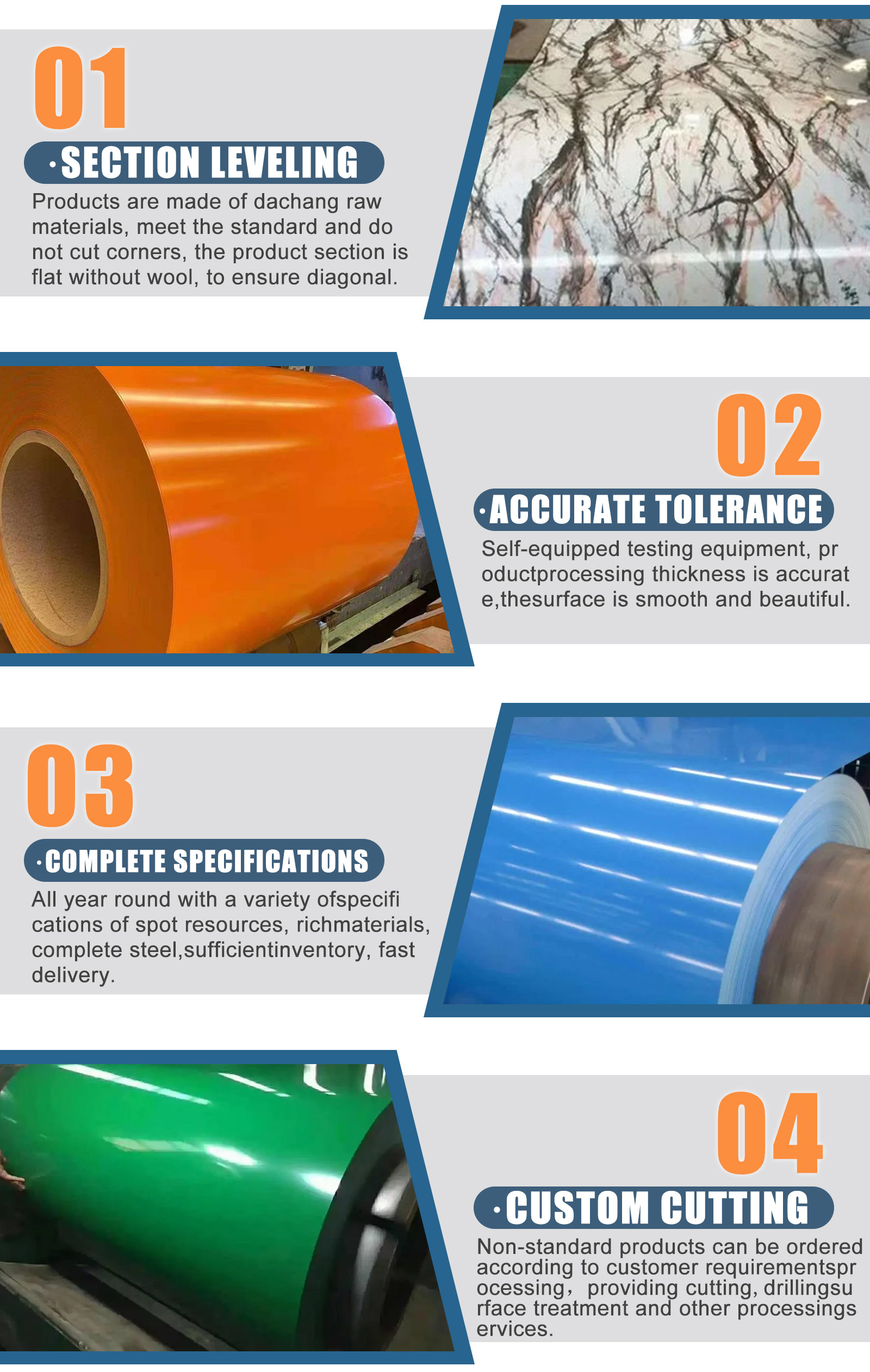

PPGI Steel Coil Description

Our PPGI is created using a meticulous process that begins with a galvanized steel substrate. This substrate is thoroughly cleaned and pre-treated to ensure optimal adhesion and longevity. Multiple layers of high-performance coatings are then applied, resulting in a final product that not only looks great but also stands the test of time. The coil coating process we use ensures uniformity and consistency in color and surface, making our PPGI coil a reliable choice for a wide variety of applications.We offer a wide range of PPGI options, including rolls, strips, sheets and corrugated sheets, all tailored to your specific needs. Whether you are looking to enhance architectural aesthetics, create durable roofing solutions or manufacture high-quality products, our PPGIs deliver exceptional performance and visual appeal.

Product Parameters

|

Product Name |

PPGI Steel Coil |

|

Thickness |

0.13mm-0.8mm |

|

Width |

600mm-1250mm |

|

Length |

Support Customization |

|

Color |

According RAL Color Card (Can provide custom pattern) |

|

Paint |

PE, SMP, HDP, PVDF |

|

Primer |

Epoxy primer, Polyester primer, Water soluble acrylic primer, Polyurethane primer |

|

Coating Thickness |

Top Coat: 10-30mic, Back Paint: 5-25mic |

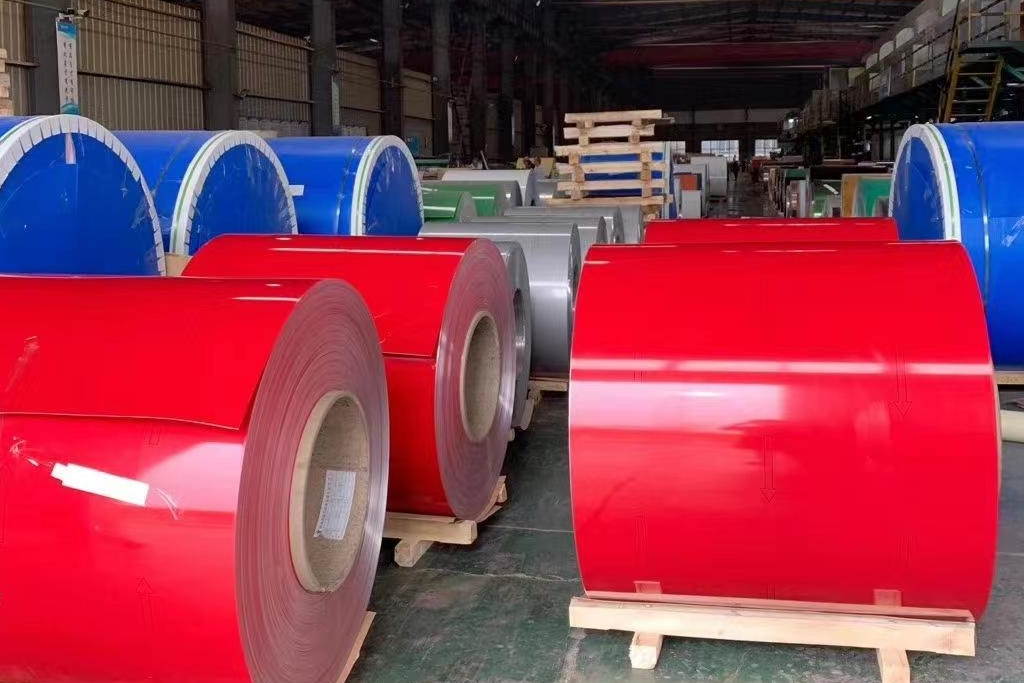

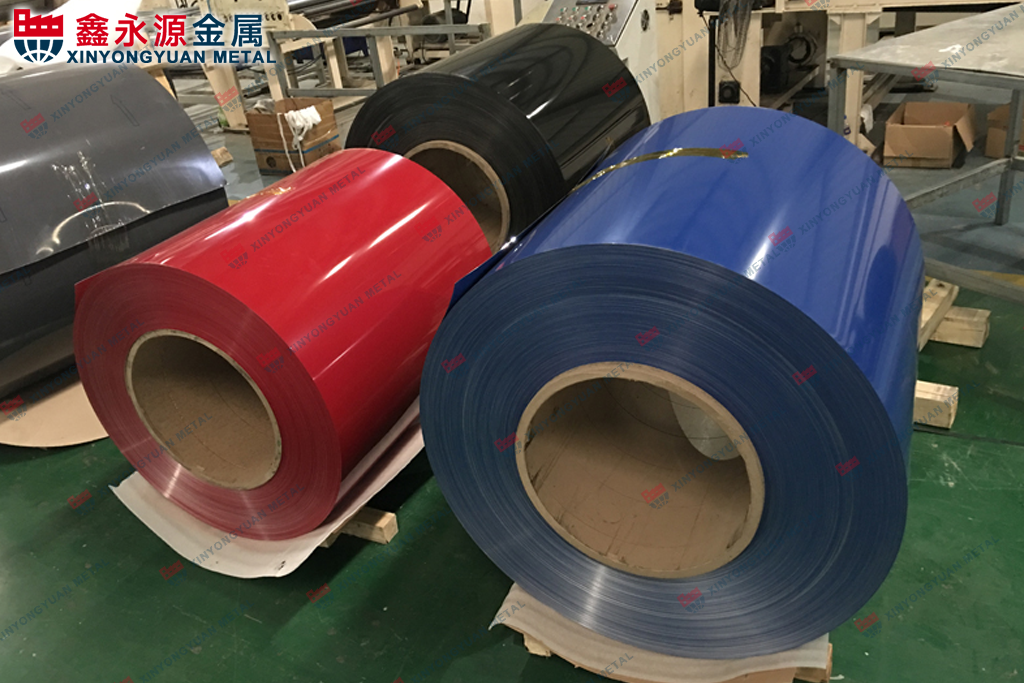

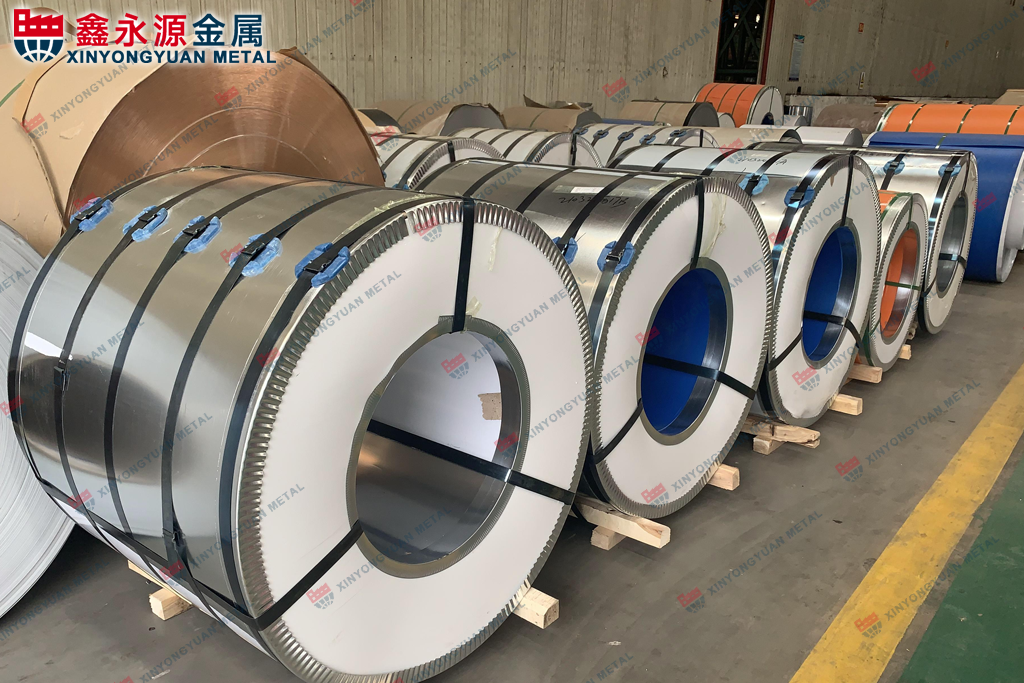

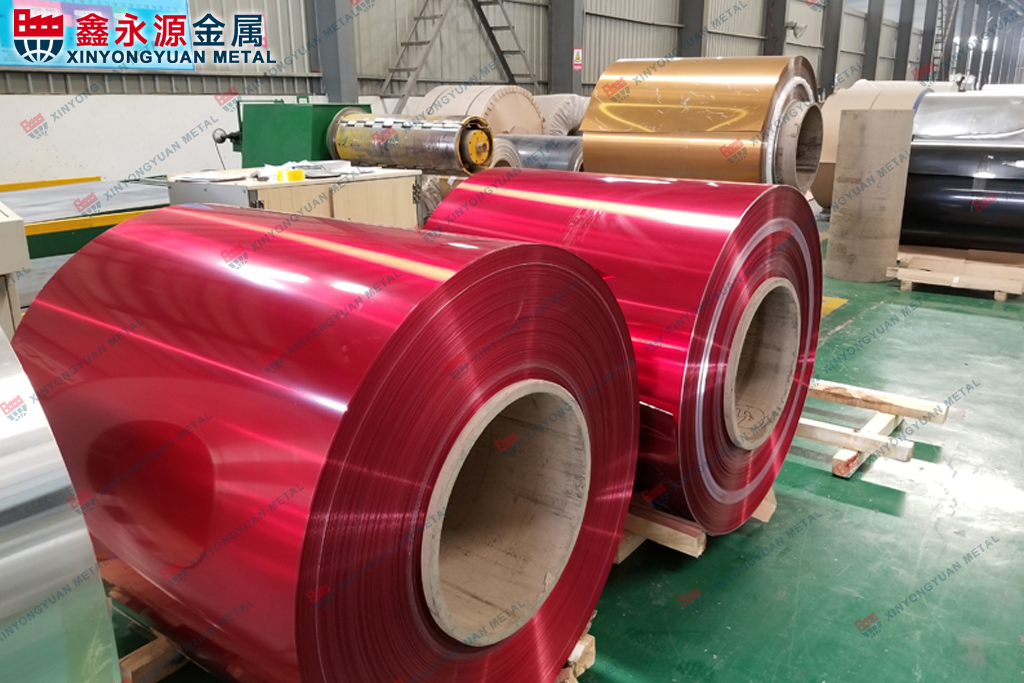

Color Selection

We provide many colors to choose from, the following are common colors, if you like other colors or patterns, please send us the RAL color code.

Surface Treatment

Laminated Film

The process is to coat a transparent organic film (30-50 µm) on the steel coil at high temperature. It has some unique properties, such as fire resistance, fingerprint resistance, excellent durability, anti-fouling ability, etc. Obviously, this treatment method can protect the steel coil well during storage and transportation.

Embossing

Embossed PPGI steel coil design has different patterns. Popular patterns are stucco, rhombus, etc. And it's customizable. Compared with the smooth steel coil, it has a vivid 3D effect.

Coating Type

In the coil coating, the durability of the role is the resin and pigment, the most commonly used finish polyester, silicon modified polyester, high durability polyester and polyvinylidene fluoride.

Polyester PE

Good adhesion, rich color, wide range in formability and outdoor durability, medium chemical resistance, low cost.

Silicon Modified Polyester Smp

The hardness, abrasion resistance and heat resistance of the coating film are good; as well as good external durability and powder resistance, gloss retention, general flexibility and medium cost.

High Durability Polyester HDP

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, good film adhesion, rich color, excellent cost performance.

Polyvinylidene Fluoride PVDF

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good formability, dirt resistance, limited color, and high cost.

Scope of Application

Construction industry: such as roof, interior and exterior wall panels, balcony panels, suspended ceilings, partition walls, windows, door panels, etc.

Transportation: For example, car trim panels, train or ship decks, containers, etc.

Electrical equipment: mainly used for making freezers, washing machines, air conditioners and other enclosures. PPGI coils for home appliances have the best quality and the highest production requirements.

Furniture: such as wardrobes, lockers, radiators, lampshades, tables, beds, bookcases, shelves, etc.

Other industries: such as roller shutters, billboards, traffic signs, elevators, whiteboards, etc.

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners