Color Coated Galvalume Steel Coil PPGL

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

Color Coated Galvalume Steel Coil PPGL Description

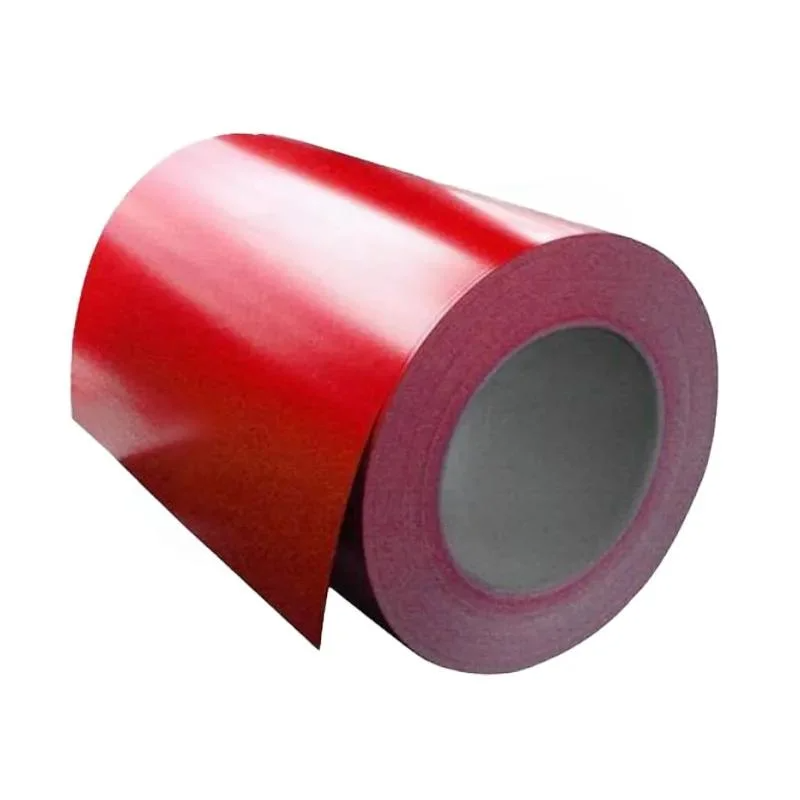

PPGL steel is a resilient, vibrant, and cost-effective building material. It is short for color-coated aluminum-zinc plated steel coil, which is derived from aluminum-zinc plated steel coil. The aluminum-zinc coated steel is subsequently continuously painted in coil form. With its heat resistance and corrosion resistance, it has become a favored material for diverse construction applications, particularly for roofs and walls. With 55% aluminum content, the corrosion resistance of PPGL coil surpasses that of PPGI, significantly extending its service life.

Product Parameters

|

Product Name |

Color Coated Galvalume Steel Coil PPGL |

|

Thickness |

0.13mm-0.8mm |

|

Width |

600mm-1250mm |

|

Length |

Support Customization |

|

Color |

According RAL Color Card (Can provide custom pattern) |

|

Paint |

PE, SMP, HDP, PVDF |

|

Primer |

Epoxy primer, Polyester primer, Water soluble acrylic primer, Polyurethane primer |

|

Coating Thickness |

Top Coat: 10-30mic, Back Paint: 5-25mic |

Color Selection

We provide many colors to choose from, the following are common colors, if you like other colors or patterns, please send us the RAL color code.

PPGL Color Coated Coil Advantages

Excellent Corrosion Resistance

Because it contains 55% aluminum, the corrosion resistance of PPGL is much better than that of PPGI, which can greatly extend the service life.

Good Heat Reflectivity

Good heat resistance can keep the building cool in the hot summer.

Weather Resistance

Pre-coated aluminum-zinc steel can withstand severe weather conditions, such as extreme summer, winter or rainfall.

Good Processing Performance

PPGL steel plate is easy to shear, profiling, blanking and other processing.

Beautiful Appearance

They have a pleasing surface finish and aesthetics that look attractive and impressive.

Coating Type

In the coil coating, the durability of the role is the resin and pigment, the most commonly used finish polyester, silicon modified polyester, high durability polyester and polyvinylidene fluoride.

Polyester PE

Good adhesion, rich color, wide range in formability and outdoor durability, medium chemical resistance, low cost.

Silicon Modified Polyester Smp

The hardness, abrasion resistance and heat resistance of the coating film are good; as well as good external durability and powder resistance, gloss retention, general flexibility and medium cost.

High Durability Polyester HDP

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, good film adhesion, rich color, excellent cost performance.

Polyvinylidene Fluoride PVDF

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good formability, dirt resistance, limited color, and high cost.

Scope of Application

Construction industry: such as roof, interior and exterior wall panels, balcony panels, suspended ceilings, partition walls, windows, door panels, etc.

Transportation: For example, car trim panels, train or ship decks, containers, etc.

Electrical equipment: mainly used for making freezers, washing machines, air conditioners and other enclosures. PPGI coils for home appliances have the best quality and the highest production requirements.

Furniture: such as wardrobes, lockers, radiators, lampshades, tables, beds, bookcases, shelves, etc.

Other industries: such as roller shutters, billboards, traffic signs, elevators, whiteboards, etc.

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners