Cutting Edge 1018 Cold Rolled Steel Plate

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

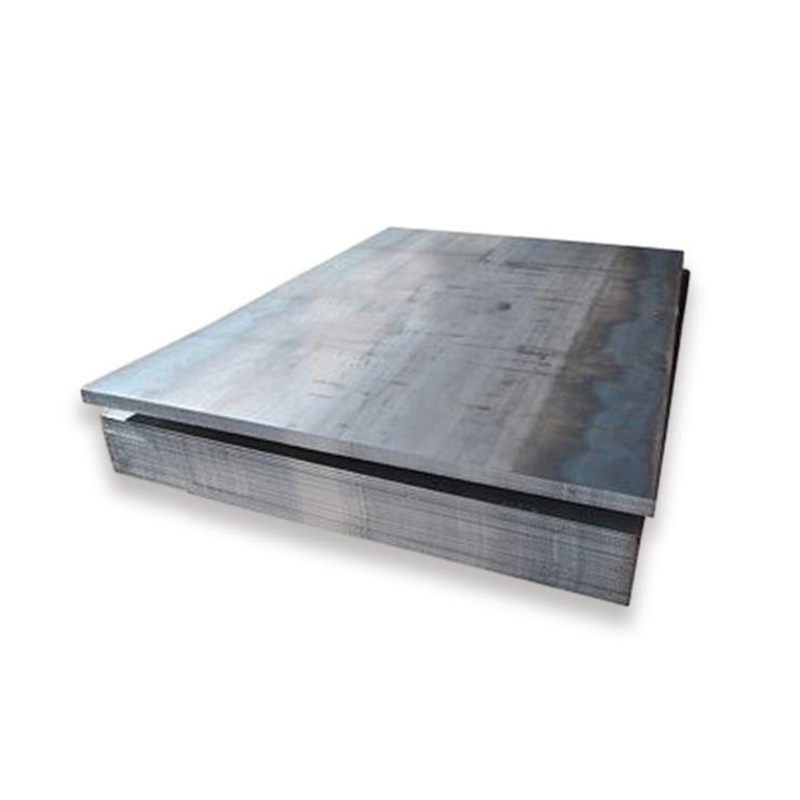

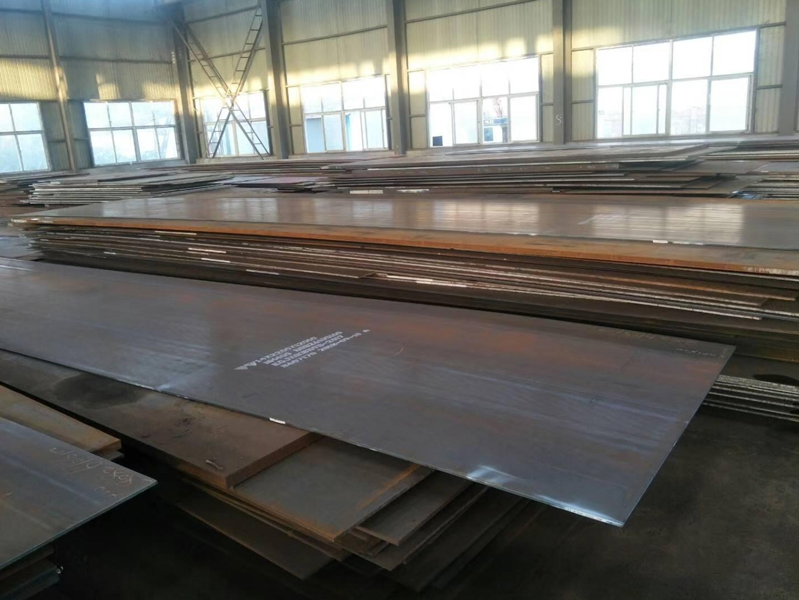

1018 Cold Rolled Steel Plate

There are numerous steel categories, and carbon steels are among them, containing 0.12 to 2% carbon. As the carbon content increases, the steel’s hardness and strength improve with heat treatment, albeit at the expense of reduced ductility.

AISI 1018 carbon steel is a widely available free machining grade that is commonly used worldwide. While its mechanical properties may not be exceptional, it is easily formable, machinable, weldable, and fabricable.

The subsequent sections will provide a detailed discussion of AISI 1018 carbon steel.

Product Parameters

| Product Name | 1008 Cold Rolled Steel Plate |

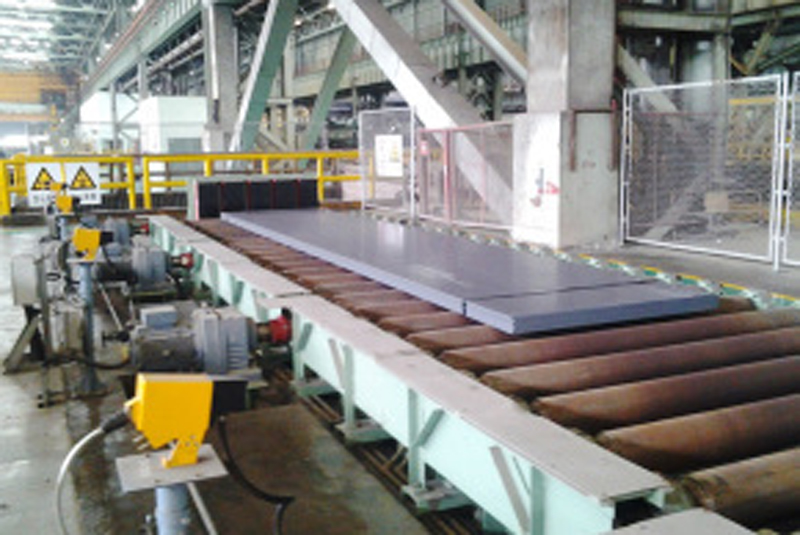

| Type | Hot Rolling, Cold Rolling |

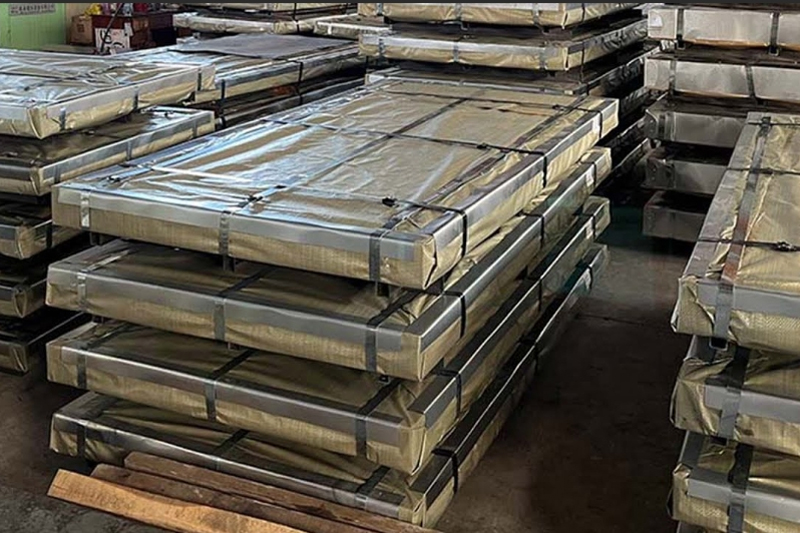

| Thickness | 0.1mm-400mm |

| Length | 1m-12m, or Customized Size |

| Width | 100mm-3000mm |

| Standard | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

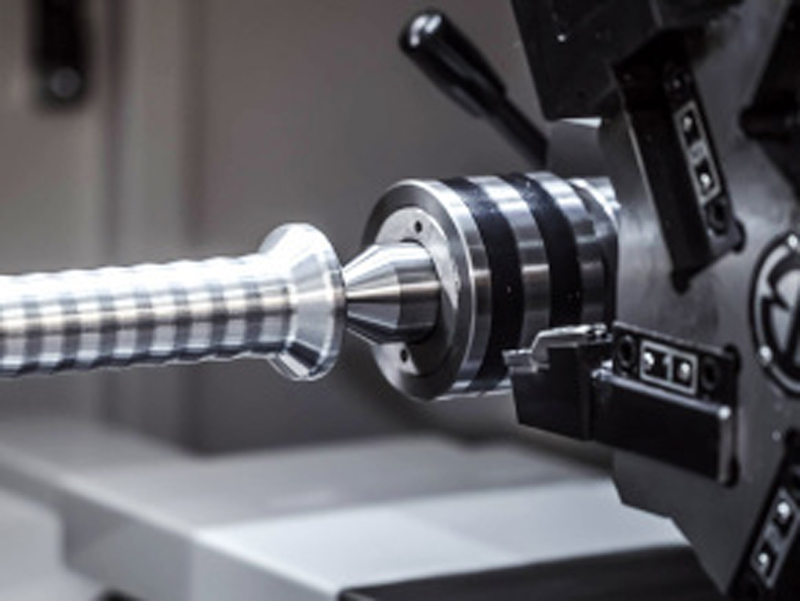

| Scope of Application | AISI 1018 carbon steel is frequently utilized in high volume screw machine parts applications. Additionally, this alloy finds application in the following areas: Shafts Spindles Pins Rods Sprocket assemblies |

| Certificate | ISO, SGS, BV, etc. |

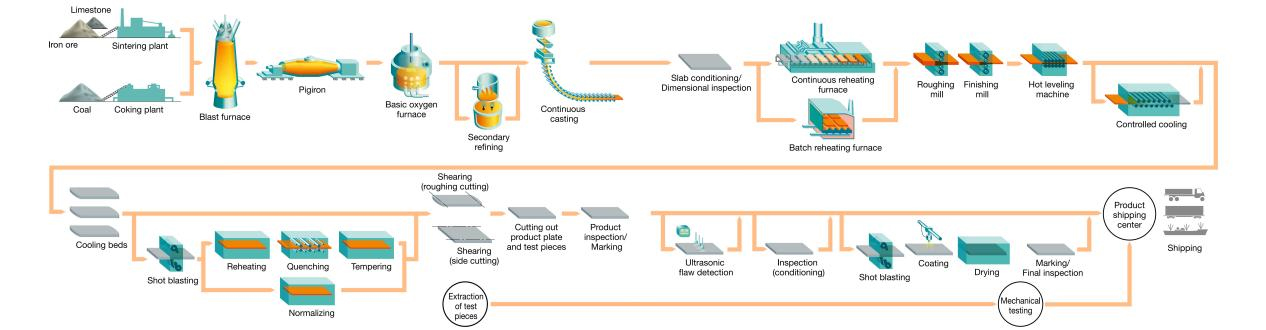

| Production Technology | Rolling, Annealing, Quenching, Tempered or Standard |

| Edge Processing | Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

| Element | Content (%) |

| Manganese, Mn | 0.60-0.90 |

| Carbon, C | 0.15-0.20 |

| Sulfur, S | 0.05 (max) |

| Phosphorous, P | 0.04 (max) |

| Iron, Fe | Balance |

Mechanical Properties

| Properties | Metric | Imperial |

| Tensile strength | 440 MPa | 63800 psi |

| Yield strength | 370 MPa | 53700 psi |

| Modulus of elasticity | 205 GPa | 29700 ksi |

| Shear modulus (typical for steel) | 80 GPa | 11600 ksi |

| Poisson’s ratio | 0.29 | 0.29 |

| Elongation at break (in 50 mm) | 15% | 15% |

| Hardness, Brinell | 126 | 126 |

| Hardness, Knoop (converted from Brinell hardness) | 145 | 145 |

| Hardness, Rockwell B (converted from Brinell hardness) | 71 | 71 |

| Hardness, Vickers (converted from Brinell hardness) | 131 | 131 |

| Machinability (based on AISI 1212 steel. as 100 machinability) | 70 | 70 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners