Cutting Edge 430 Stainless Steel Bar

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

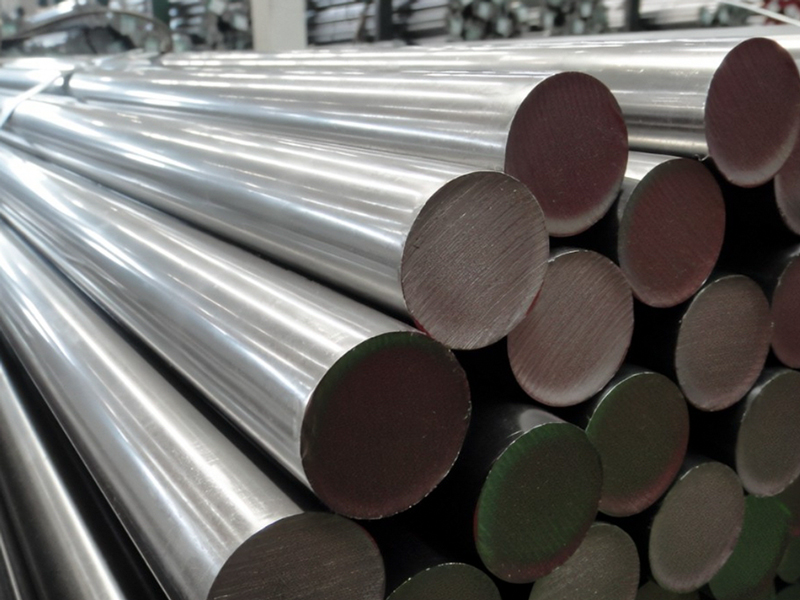

430 Stainless Steel Bar Description

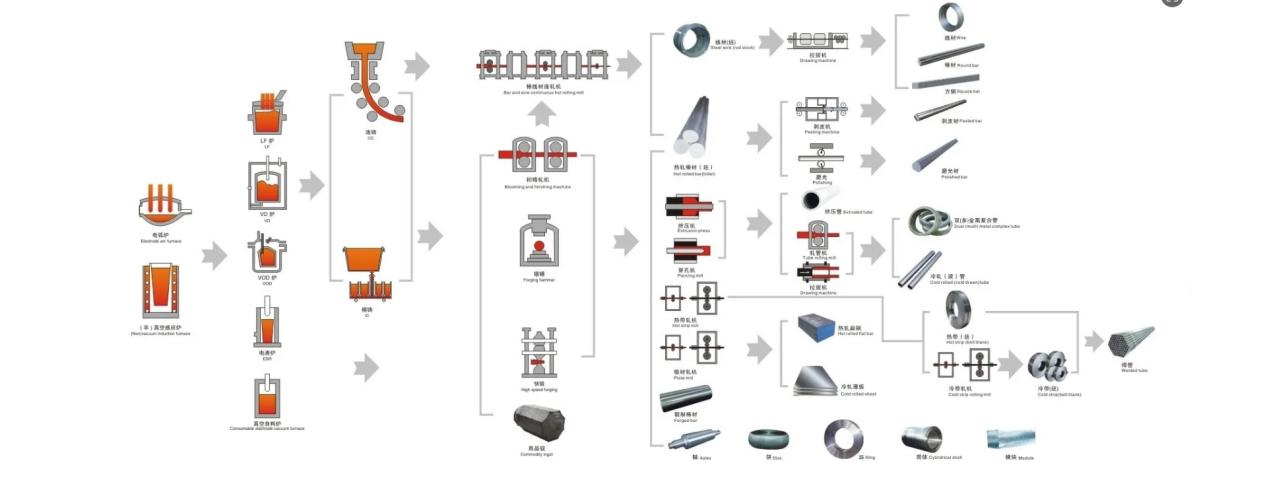

430 stainless steel bars are renowned for their exceptional resistance to oxidation and rust in humid or mildly corrosive environments. The presence of chromium forms an invisible protective layer on the surface, effectively preventing rust. Additionally, this steel material offers the advantage of maintaining its strength and resilience at high temperatures without becoming brittle. Industries frequently utilizing 430 stainless steel bars for manufacturing components include aerospace engineering, medical device manufacturing, petrochemical processing plants, and marine applications. However, welding 430 stainless steel can be challenging due to its high chromium content. Thoroughly cleaning the bars with a wire brush to remove any discoloration caused by heat exposure during the welding process is essential.

Product Parameters

| Product Name | 430 Stainless Steel Bar | |

| Type | Steel Bar | |

| Outer Diameter | Round Bar | 4mm-500mm |

| Hexagon Bar | 18mm-57mm (11/16″ to 2-3/4″) | |

| Square Bar | 18mm-47mm (11/16″ to 1-3/4″) | |

| Flat Steel | 1/2 "to 10", Thickness: 2mm-150mm, Can provide customized | |

| Length | 1-6 meters, Length can be customized | |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

| Surface | Black, Bright Polished, Rough Turning, Mattness Surface Treatment, No. 4. BA, etc. | |

| Scope of Application | Stainless steel bars find applications across a diverse range of industries, including shipbuilding, defense, automotive, textiles, paper and pulp, manufacturing, cement, heavy earthmoving equipment, and construction. | |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.12 | ≤1.0 | ≤1.0 | 16.0~18.0 | ≤0.75 | ≤ 0.03 | ≤ 0.04 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥634 | ≥440 | ≥20 | Annealing≤ 223HB; quenching and tempering ≥ 192HB |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 7.70 | 200 | 10.4 | 23.9 | 360 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners