Elite AISI/SAE 1025 Round Steel Bar

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

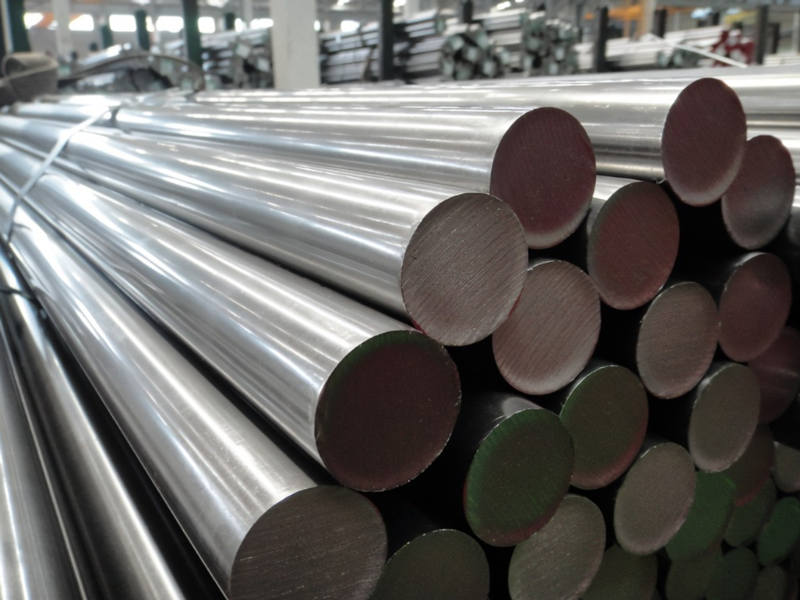

AISI/SAE 1025 Round Steel Bar Description

Under standard conditions, AISI1025 steel bars demonstrate favorable corrosion resistance. Due to its lower carbon content, it is less resistant to corrosion compared to stainless steel and high-strength alloy steel. However, when subjected to appropriate conditions, the corrosion resistance of AISI1025 components can be enhanced through surface treatment with a thin film. Additionally, AISI1025 can undergo heat treatment to enhance its strength and hardness, achieved through quenching and tempering at elevated temperatures. These steel bars are commonly employed in the production of bolts, nuts, and other mechanical industrial parts. AISI1025 steel boasts excellent processability and is easily weldable. Furthermore, the hardness of AISI1025 steel is readily controllable, making it a widely utilized material for manufacturing metal parts.

Product Parameters

| Product Name | AISI/SAE 1025 Round Steel Bar | |||

| Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. | |||

| Common Round Bar Specifications | 3.0-50.8 mm, Over 50.8-300mm | |||

| Flat Steel Common Specifications | 6.35x12.7mm, 6.35x25.4mm, 12.7x25.4mm | |||

| Hexagon Bar Common Specifications | AF5.8mm-17mm | |||

| Square Bar Common Specifications | AF2mm-14mm, AF6.35mm, 9.5mm, 12.7mm, 15.98mm, 19.0mm, 25.4mm | |||

| Length | 1-6meters, Size Accept Custom | |||

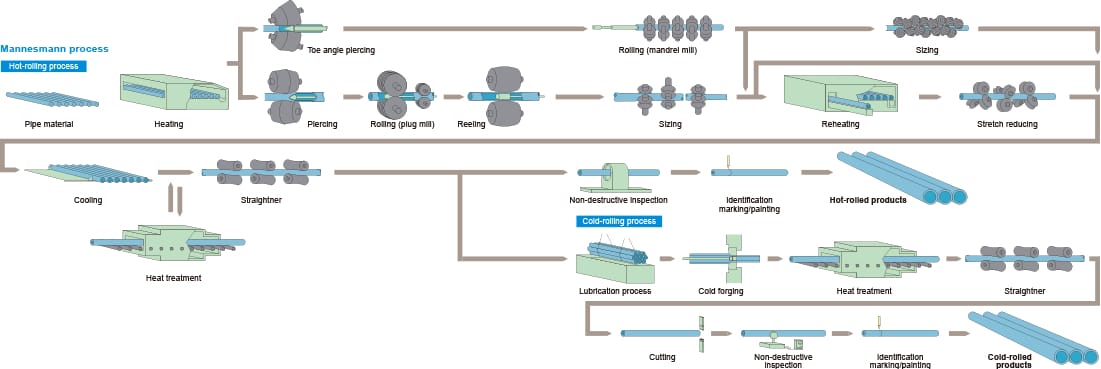

| Diameter(mm) | Hot Rolling Round Bar | 25-600 | Cold Rolling Square Bar |

6-50.8 |

| Hot Rolling Square Bar |

21-54 |

Cold Rolling Hexagon Bar |

9.5-65 |

|

| Cold Rolling Round bar | 6-101.6 | Forged Rebar |

200-1000 |

|

| Surface Process | Bright, Polished, Black | |||

| Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |||

Chemical Composition

|

1025 |

C |

Si |

Mn |

S |

P |

Cr |

Ni |

Cu |

|

0.62-0.70 |

0.17-0.37 |

0.90-1.20 |

≤ 0.035 |

≤ 0.035 |

≤0.25 |

≤0.25 |

≤0.25 |

Mechanical Properties

|

1025 |

Tensile Strength |

Yield Strength |

Elongation |

Reduction of Area Meat |

Hardness |

|||

|

(Mpa) |

(Mpa) |

(%) |

(%)min |

Hot Rolled |

Cold Rolled Soft |

Cold Rolled Hard |

Heat Treatment |

|

|

825-925 |

520-690 |

14-21.5 |

10 |

240-270HB |

190-220HB |

300-340HB |

38-60HRC |

|

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners