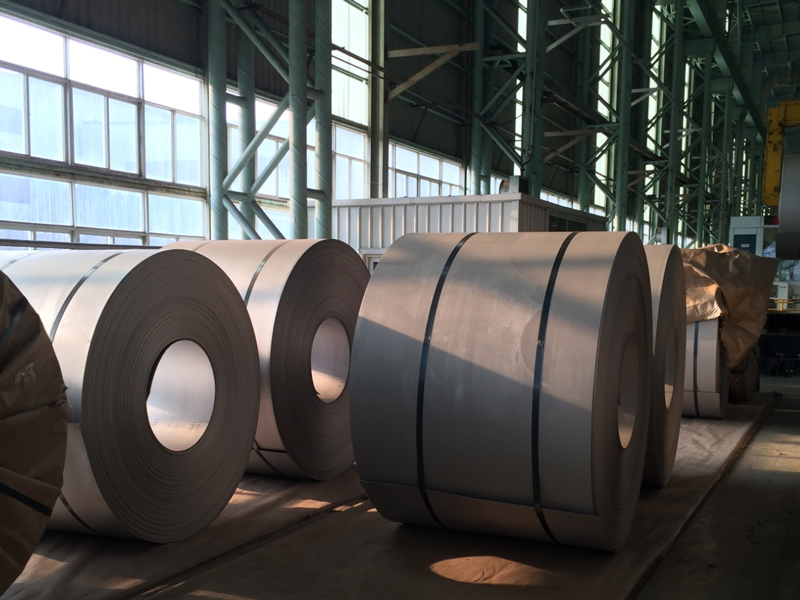

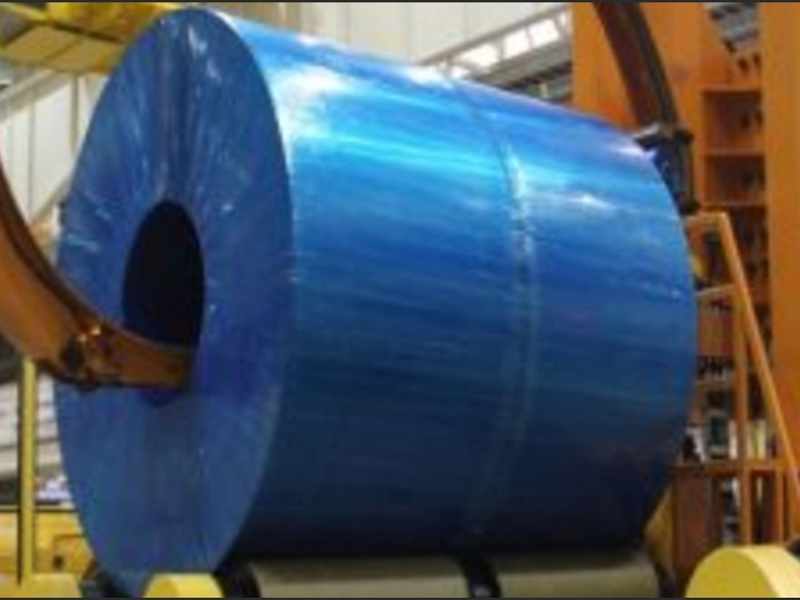

Fine Grade 1008 Cold Rolled Steel Coil

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

1008 Cold Rolled Steel Coil description

Product Parameters

| Product Name | 1008 Cold Rolled Steel Coil |

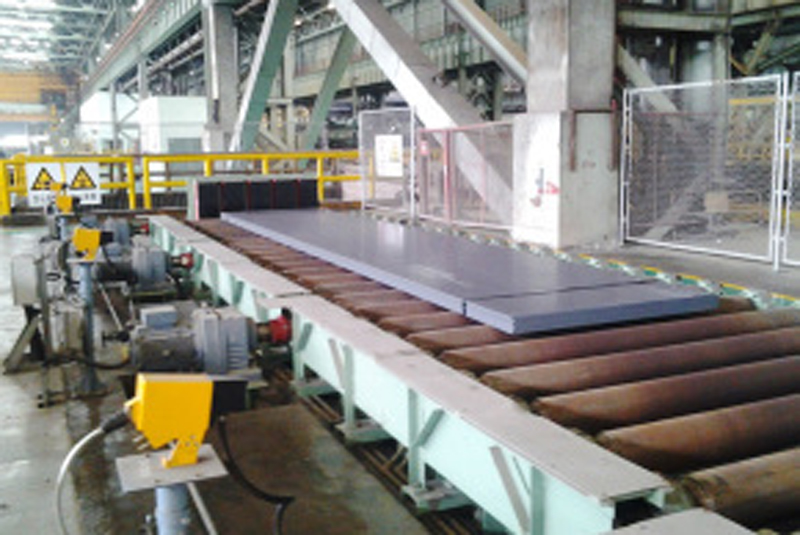

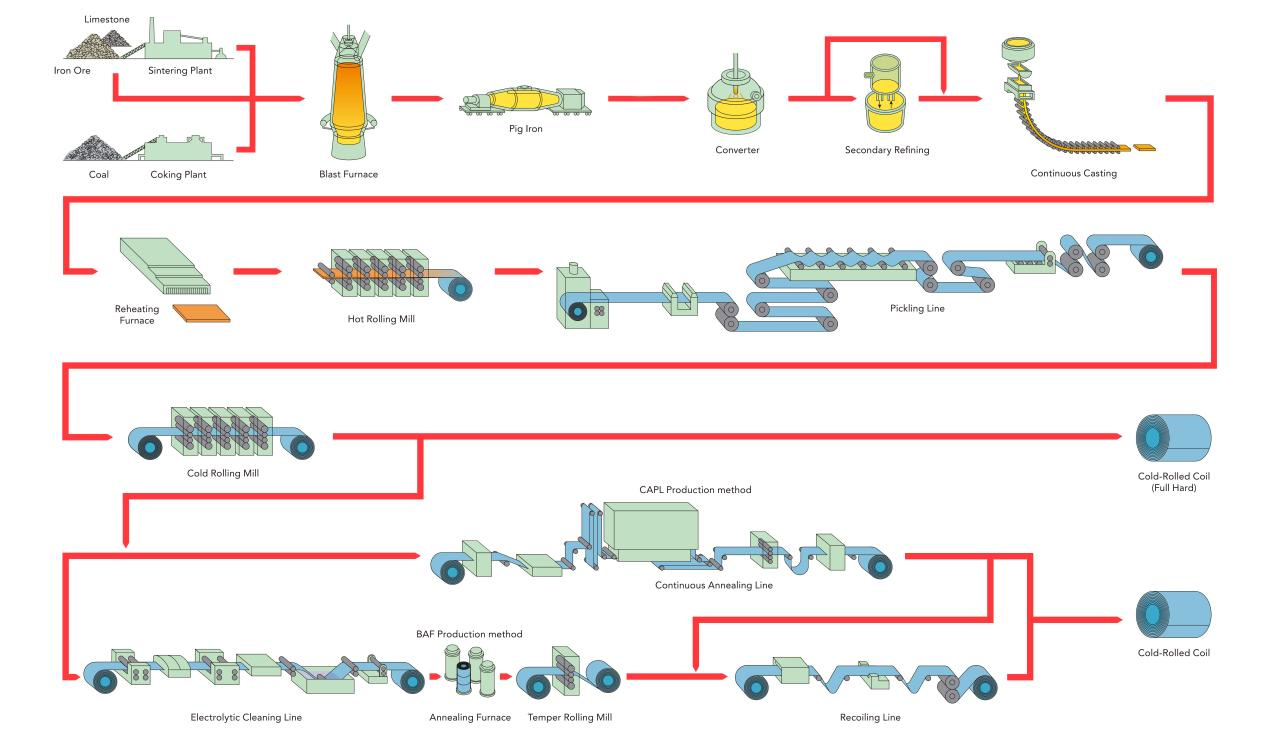

| Production Process | Hot Rolling, Cold Rolling |

| Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

| Width | 45mm-2200mm |

| Length | Custom Size |

| Thickness | Hot Rolling: 2.75mm-100mm Cold Rolling: 0.2mm-3mm |

| Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

| Surface Process | Ordinary, Wire Drawing, Laminated Film |

| Scope of Application | AISI 1008 carbon steel is predominantly utilized in extruded, cold headed, cold upset, and cold pressed parts and forms. |

Chemical Composition

|

Element |

Content (%) |

|

Iron, Fe |

99.31-99.7 % |

|

Manganese, Mn |

0.30-0.50 % |

|

Carbon, C |

0.10 % |

|

Sulfur, S |

0.050 % |

|

Phosphorous, P |

0.040 % |

Mechanical Properties

|

Properties |

Metric |

Imperial |

|

Tensile strength |

340 MPa |

49300 psi |

|

Yield strength (depending on temper) |

285 MPa |

41300 psi |

|

Elastic modulus |

190-210 Gpa |

27557-30458 ksi |

|

Bulk modulus (typical for steel) |

200 GPa |

29000 ksi |

|

Shear modulus (typical for steel) |

80.0 GPa |

11600 ksi |

|

Poisson’s ratio |

0.27-0.30 |

0.27-0.30 |

|

Elongation at break (in 50 mm) |

20% |

20% |

|

Reduction of area |

45% |

45% |

|

Hardness, Brinell |

95 |

95 |

|

Hardness, Knoop (converted from Brinell hardness) |

113 |

113 |

|

Hardness, Rockwell B (converted from Brinell hardness) |

55 |

55 |

|

Hardness, Vickers (converted from Brinell hardness) |

98 |

98 |

|

Machinability (based on AISI 1212 steel as 100 machinability) The machinability of group I bar, rod, and wire products can be improved by cold drawing) |

55 |

55 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners