First Class 410 Stainless Steel Coil

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

410 Stainless Steel Coil Description

410 stainless steel is a type of martensitic stainless steel with a chromium content of 11.5%, designed to provide excellent corrosion resistance. It undergoes quenching, tempering, and polishing processes to enhance both its corrosion resistance and hardness. While martensitic stainless steel is generally less corrosion-resistant compared to austenitic stainless steel, it requires a final heat treatment during manufacturing to optimize its properties. Grade 410 stainless steel is resilient against hot gases, steam, food, weak acids and bases, fresh water, and dry air. This steel is hardened to maximize its resistance to corrosion and heat. Its high strength makes it particularly well-suited for applications that demand durability and wear resistance.

Stainless steel AISI 410 has undergone a specialized heat treatment, resulting in a hardened and tempered, double-hardened product that meets NACE standards. AISI 410 is a martensitic stainless steel known for its good corrosion resistance in moderately aggressive, chloride-free environments such as organic acids, soaps, and solvents. For optimal corrosion resistance, surface polishing is recommended.

This stainless steel features a chromium content of 11.5 – 13.5% and is characterized by its low susceptibility to embrittlement, the ability to achieve a mirror finish, and its application range up to 400°C. We manufacture our AISI 410 rectangular bars to the highest standards, ensuring consistent quality throughout.

Product Parameters

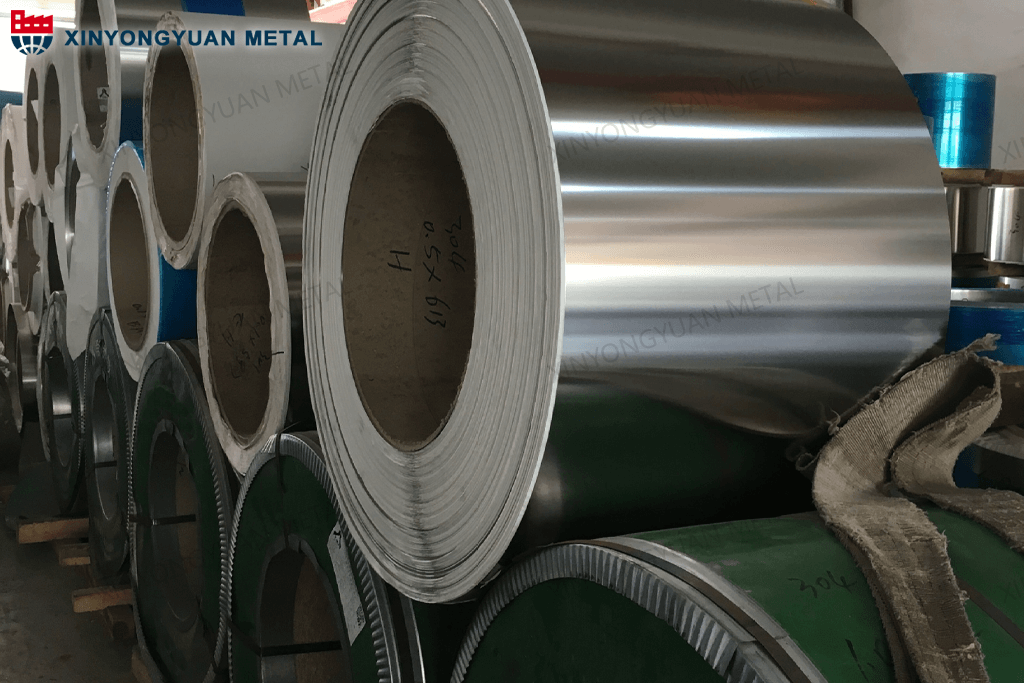

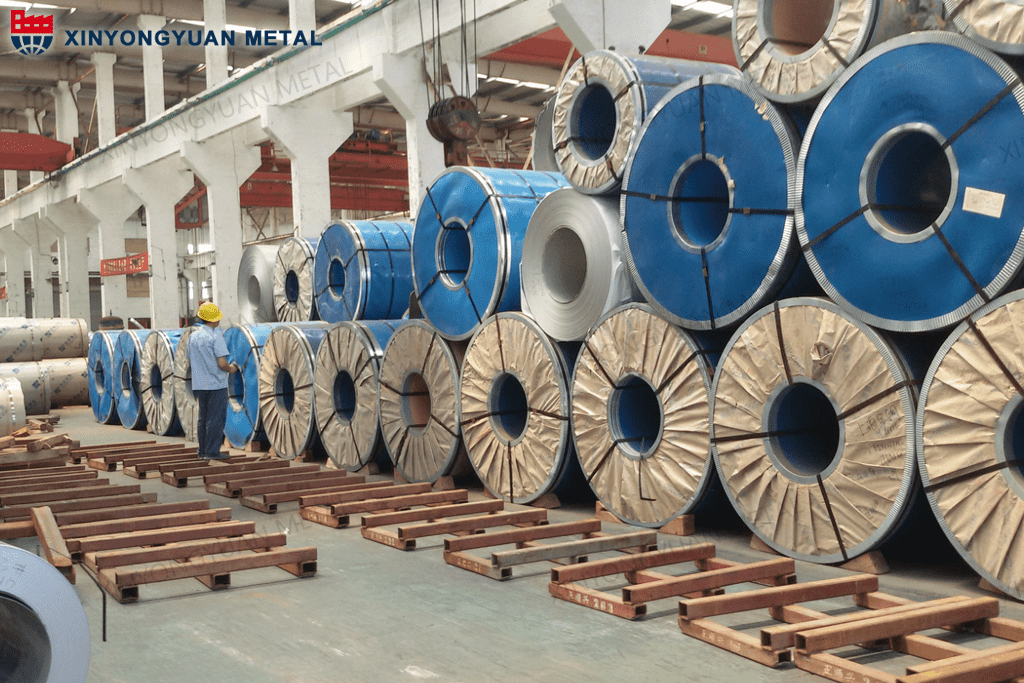

| Product Name | 410 Stainless Steel Coil |

| Type | Steel Coil |

| Thickness | 2.5mm-10.0mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

| Width | 610mm-2000mm |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

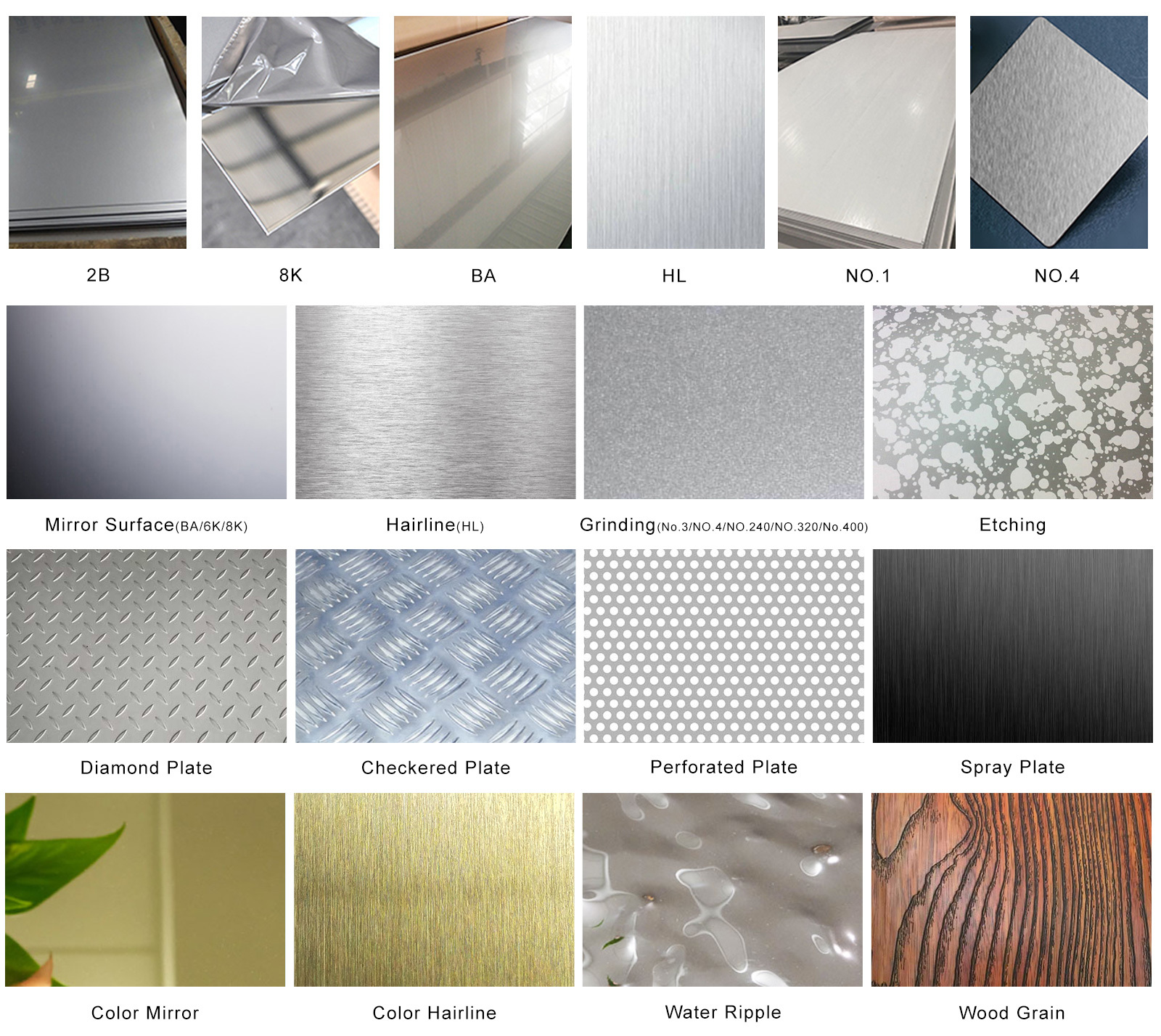

| Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

| Scope of Application | This stainless steel is widely employed in various industries, including high-temperature and electrical sectors, medical equipment construction, chemical and food industries, agriculture, ship parts, food and beverage packaging, kitchen supplies, trains, airplanes, conveyor belts, vehicles, as well as in bolts, nuts, springs, and screens, among other applications. |

| Certificate | ISO, SGS, BV, etc. |

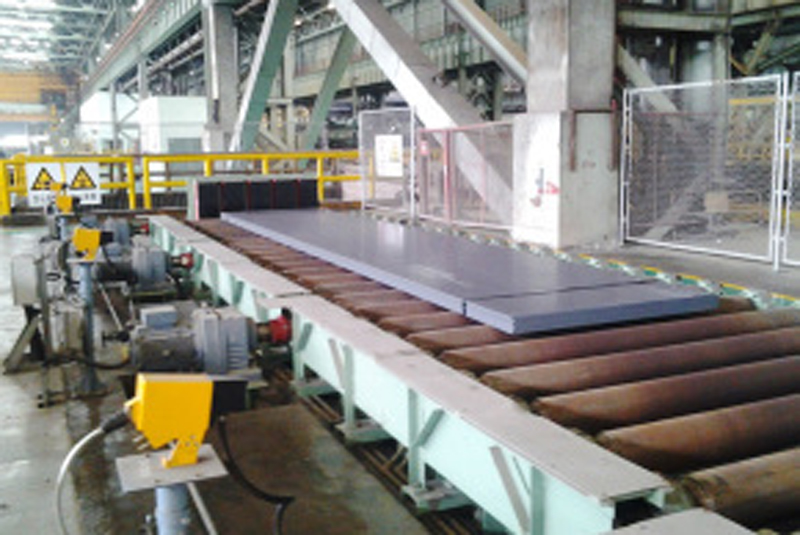

| Production Technology | Hot Rolling, Cold Rolling |

| Edge Processing | Edging, Trimming |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.15 | ≤ 1.0 | ≤ 1.0 | 11.5~13.5 | ≤ 0.5 | ≤ 0.03 | ≤ 0.04 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥450 | ≥205 | ≥20 | ≤ 201HB |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 7.74 | 200 | 9.9 | 24.9 | 570 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners