For Industrial Use 302 Stainless Steel Plate

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

302 Stainless Steel Plate Description

Product Parameters

|

Product Name |

302 Stainless Steel Plate |

|

Type |

Plate |

|

Thickness |

0.3mm-200mm |

|

Length |

2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. |

|

Width |

40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. |

|

Standard |

ASTM, AISI, JIS, GB, DIN, EN, etc. |

|

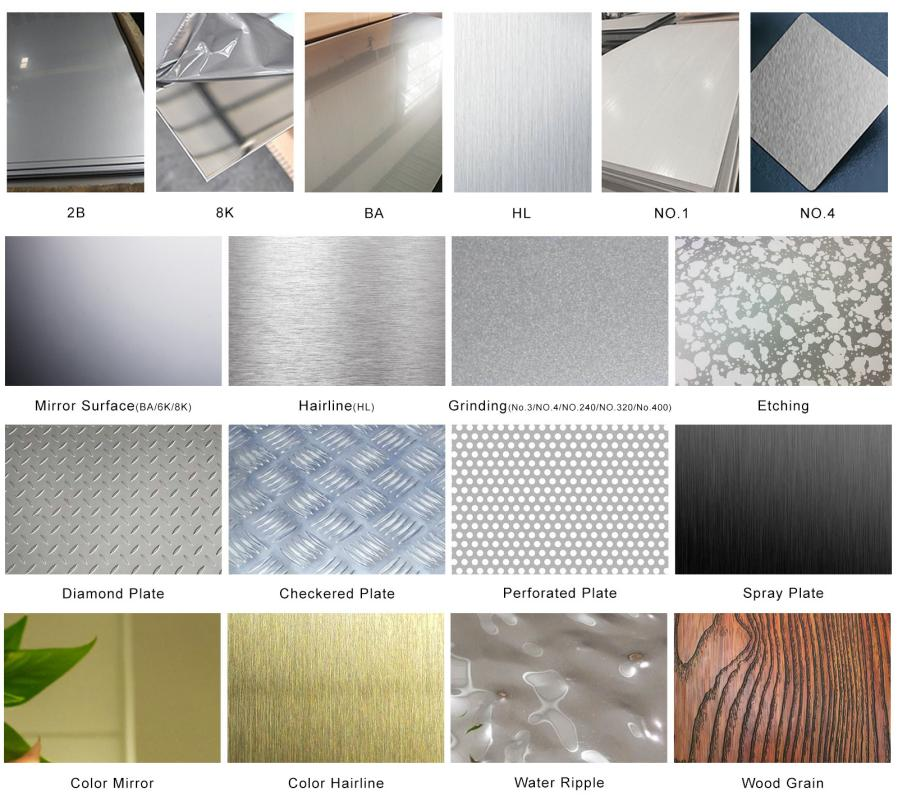

Surface |

BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

|

Scope of Application |

Common applications for these stainless steel grades include high-temperature and electrical industries, medical equipment construction, chemical and food industries, agriculture and ship parts, food and beverage packaging, kitchen supplies, trains, airplanes, conveyor belts, vehicles, as well as in bolts, nuts, springs, and screens, among others. |

|

Certificate |

ISO, SGS, BV, etc. |

|

Production Technology |

Hot Rolling, Cold Rolling |

|

Edge Processing |

Edging, Trimming |

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

S |

P |

|

≤ 0.15 |

≤1.0 |

≤ 2.0 |

17.0~19.0 |

8.0~10.0 |

≤ 0.03 |

≤ 0.035 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥520 |

≥205 |

≥40 |

≤ 187HB ;≤ 90HRB;≤ 200HV |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

7.93 |

100 |

17.6 |

16.3 |

27.4 |

Surface Selection

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners