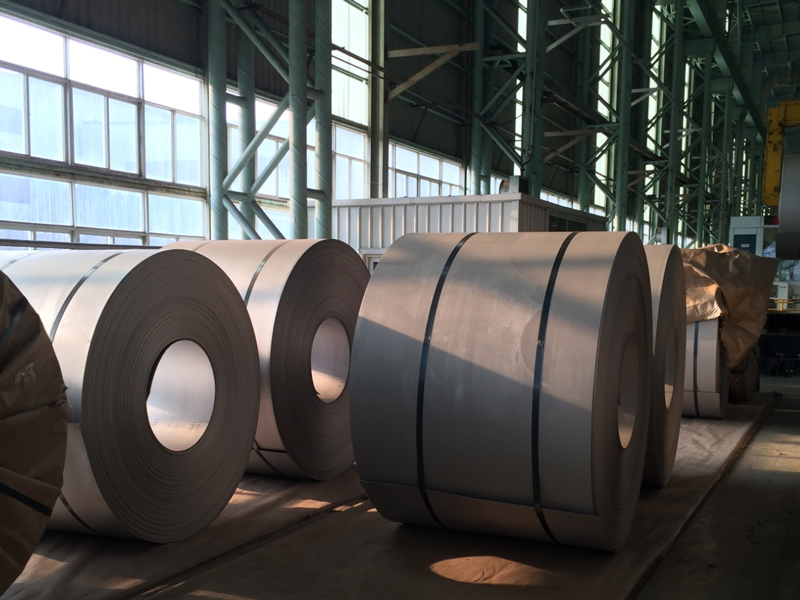

GB/T11251 1345 Alloy Structural Steel Coil

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

GB/T11251 1345 Alloy Structural Steel Coil description

GB/T 11251 alloy structural steel coil exhibits high strength and wear resistance, along with high hardenability, moderate cold deformation plasticity, good cutting performance, and excellent welding capabilities. The steel’s toughness experiences minimal reduction during heat treatment and can maintain high toughness under water cooling conditions. However, it is susceptible to overheating sensitivity, white point sensitivity, and temper brittleness. Typically used after quenching and tempering, it can also be employed under positive inflammation or hot rolling conditions. Common applications include valve bodies, pumps, fittings, wheels, bolts, studs, gears, high-load internal combustion engine components, drive shafts, steel balls, rollers, bushings for electric locomotives, machine tools, tractors, steel rolling equipment, boring machines, railway vehicles, and mining machinery.

Product Parameters

| Product Name | GB/T11251 1345 Alloy Structural Steel Coil |

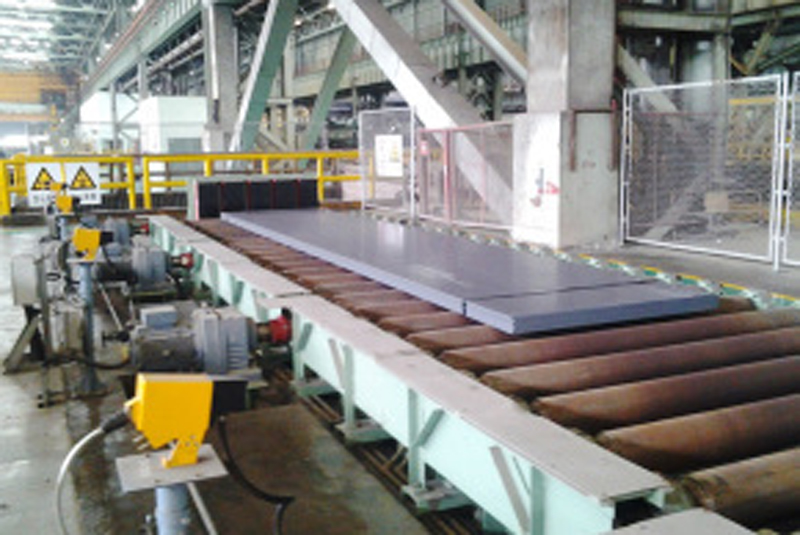

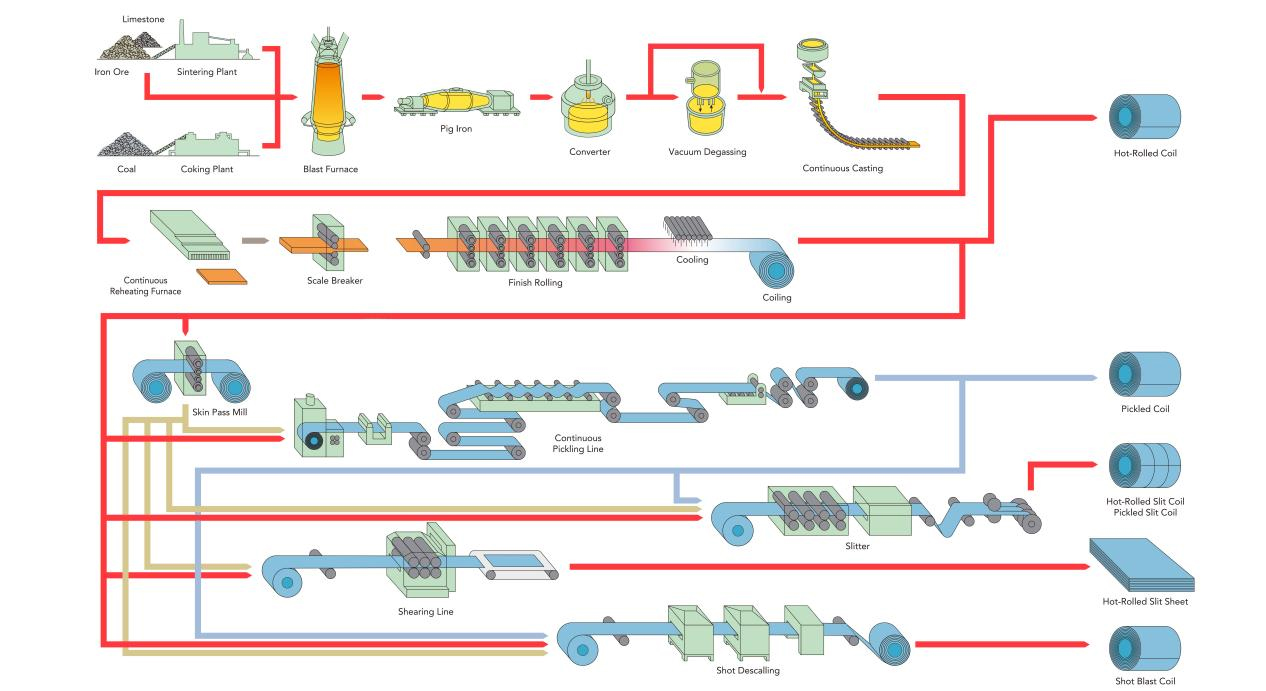

| Production Process | Hot Rolling, Cold Rolling |

| Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

| Width | 45mm-2200mm |

| Length | Custom Size |

| Thickness | Hot Rolling: 2.75mm-100mm Cold Rolling: 0.2mm-3mm |

| Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

| Surface Process | Ordinary, Wire Drawing, Laminated Film |

| Scope of Application | GB/T 11251 alloy steel plates find extensive use in a variety of applications, including bearings and gears for rotating machinery. Typical applications encompass valve bodies, pumps, fittings, wheels, bolts, studs, gears, high-load internal combustion engine components, drive shafts for electric locomotives, machine tools, tractors, steel rolling equipment, boring machines, railway vehicles, and mining machinery, involving steel balls, rollers, and bushings. |

Chemical Composition

| Brand | C | Si | Mn | B |

| 45Mn2 | 0.42~0.49 | 0.17~0.37 | 1.40~1.80 | - |

| 27SiMn | 0.24~0.32 | 1.10~1.40 | 1.10~1.40 | - |

| 40B | 0.37~0.44 | 0.17~0.37 | 0.60~0.90 | 0.0005~0.0035 |

| 45B | 0.42~0.49 | 0.17~0.37 | 0.60~0.90 | 0.0005~0.0035 |

| 50B | 0.47~0.55 | 0.17~0.37 | 0.60~0.90 | 0.0005~0.0035 |

Mechanical Properties

| Brand | Yield Strength MPa min. | Elongationmin.% | Brand |

| 45Mn2 | 600 | 13 | 45Mn2 |

| 27SiMn | 550 | 18 | 27SiMn |

| 40B | 500 | 20 | 40B |

| 45B | 550 | 18 | 45B |

Equivalent Material

| China | United States | Germany | Japan | France |

| 45Mn2 | 1345 | 46Mn7 | SMn3 | 45M5 |

| 27SiMn | - | 27MnSi5 | - | |

| 40B | 14B35 | 35B2 | - | - |

| 45B | 50B46H | 45B2 | - | - |

| 50B | 14B50 | - | - | - |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners