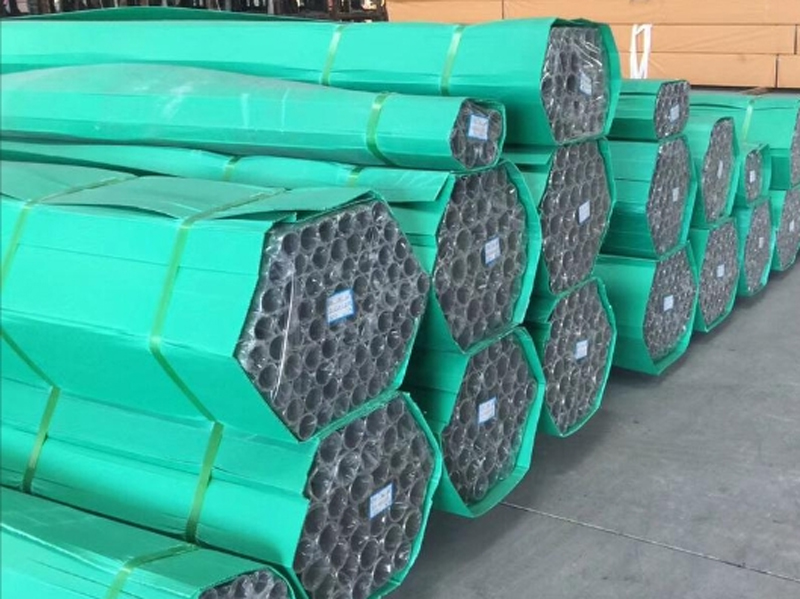

Heavy Duty 316L Stainless Steel Pipe

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

316L Stainless Steel Pipe Description

316L stainless steel pipe contains a lower carbon content compared to 316 stainless steel pipe, making it suitable for welding applications. The reduced carbon content significantly minimizes the precipitation of carbides in the heat-affected zone near the weld, which is closely linked to intergranular corrosion of stainless steel in certain environments. Notably, there is no need to anneal weld joints prior to using the completed metal form. 316L stainless steel pipe is the second most prevalent stainless steel after 304, offering superior corrosion resistance compared to 304. It also exhibits improved high-temperature resistance, up to 1000 degrees. Widely regarded as a universal stainless steel material, 316L stainless steel pipe is extensively used in the chemical industry due to its exceptional corrosion resistance.

Product Parameters

| Product Name | 316L Stainless Steel Pipe | |

| Type | Steel Pipe | |

| Outer diameter | Round Tube | 4mm-200mm |

| Square Tube | 10*10mm-100*100mm | |

| Rectangular Tube | 10*20mm-50*100mm | |

| Wall Thickness | 0.6mm-6.0mm | |

| Length | 1-6 meters, Length can be customized | |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

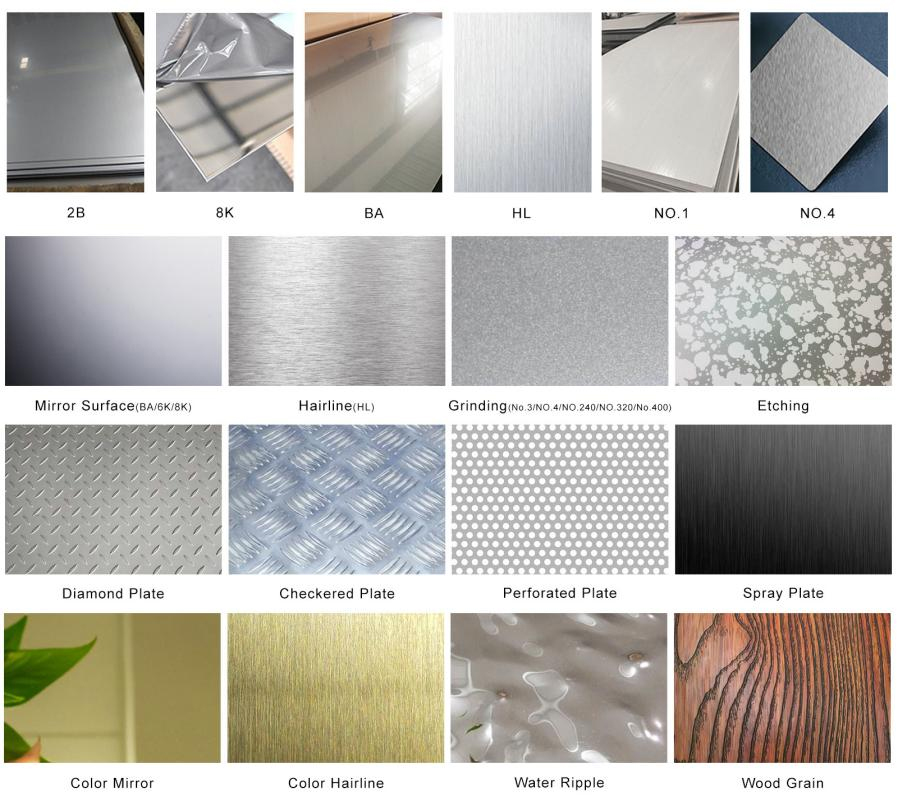

| Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. | |

| Scope of Application | Stainless steel pipes are commonly employed in various industries such as food processing, textile operations, breweries, water treatment plants, oil and gas processing, fertilizers and pesticides production, chemical applications, construction, pharmaceuticals, and auto parts manufacturing, among others. | |

| Certificate | ISO, SGS, BV, etc. | |

| Production Technology | Hot Rolling, Cold Rolling | |

| Edge Processing | Edging, Trimming | |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P | Mo |

| ≤ 0.03 | ≤1.0 | ≤ 2.0 | 16.0~18.0 | 10.0~14.0 | ≤ 0.03 | ≤ 0.045 | 2.0~3.0 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥480 | ≥177 | ≥ 40 | ≤ 187HB;≤ 90HRB;≤ 200HV |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 7.99 | 193 | 16.0 | 16.2 | 74 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners