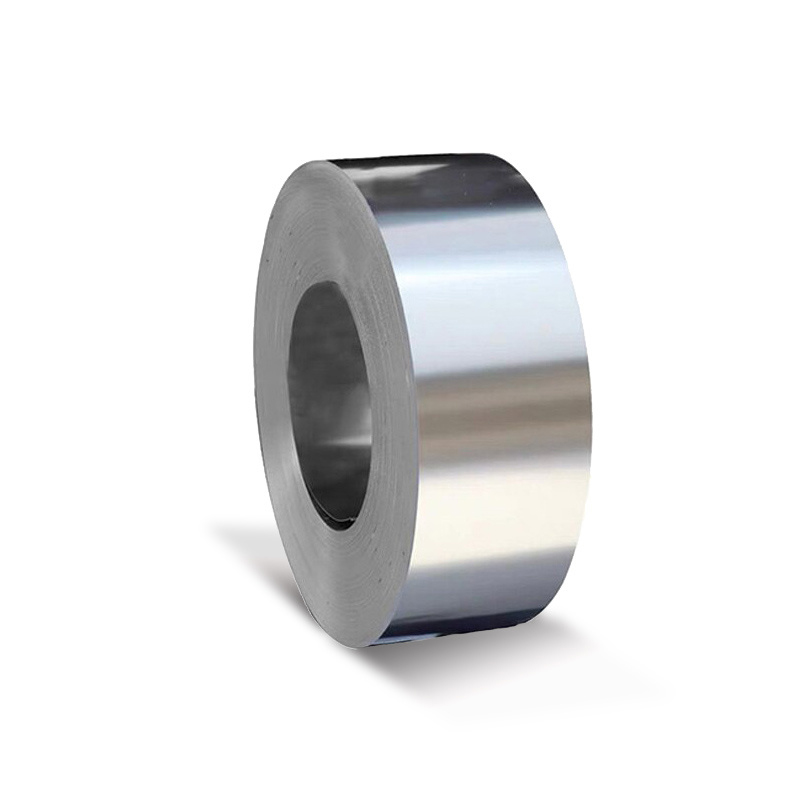

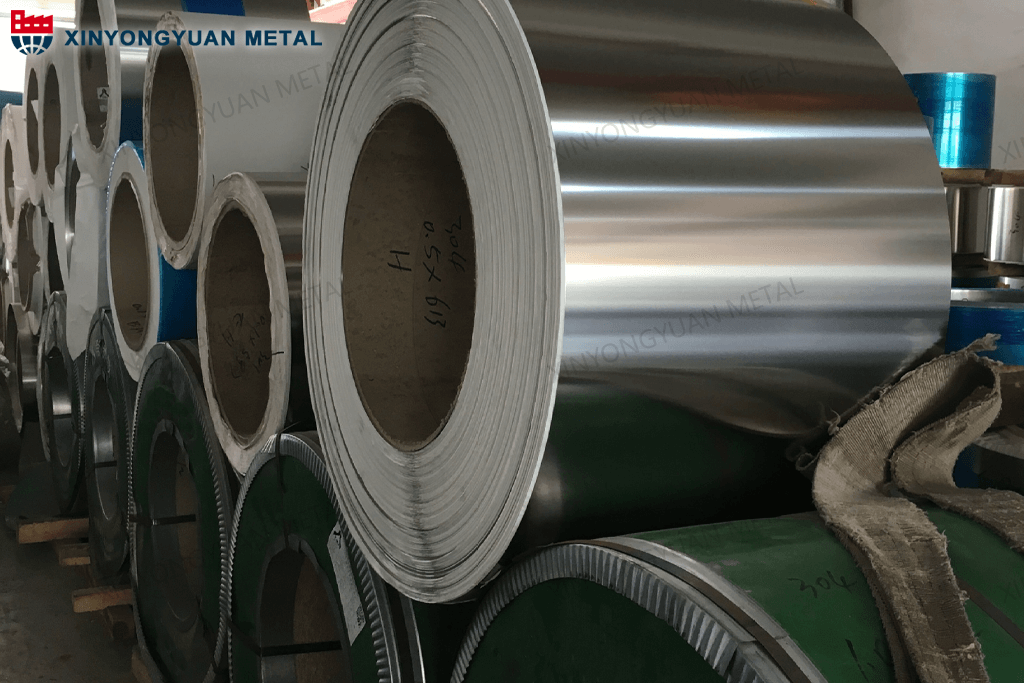

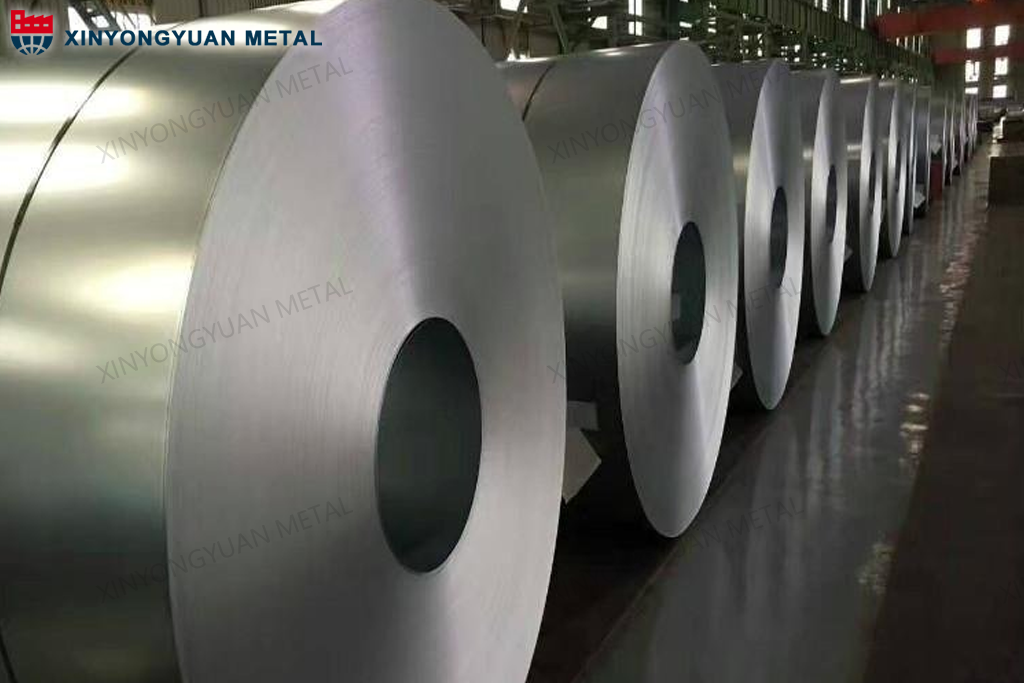

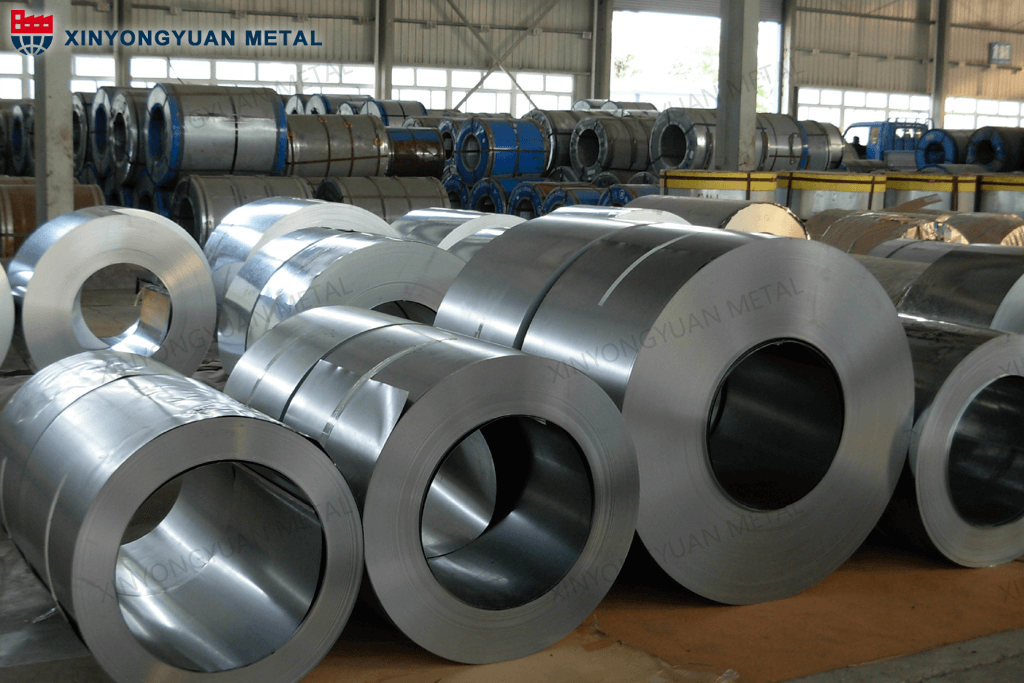

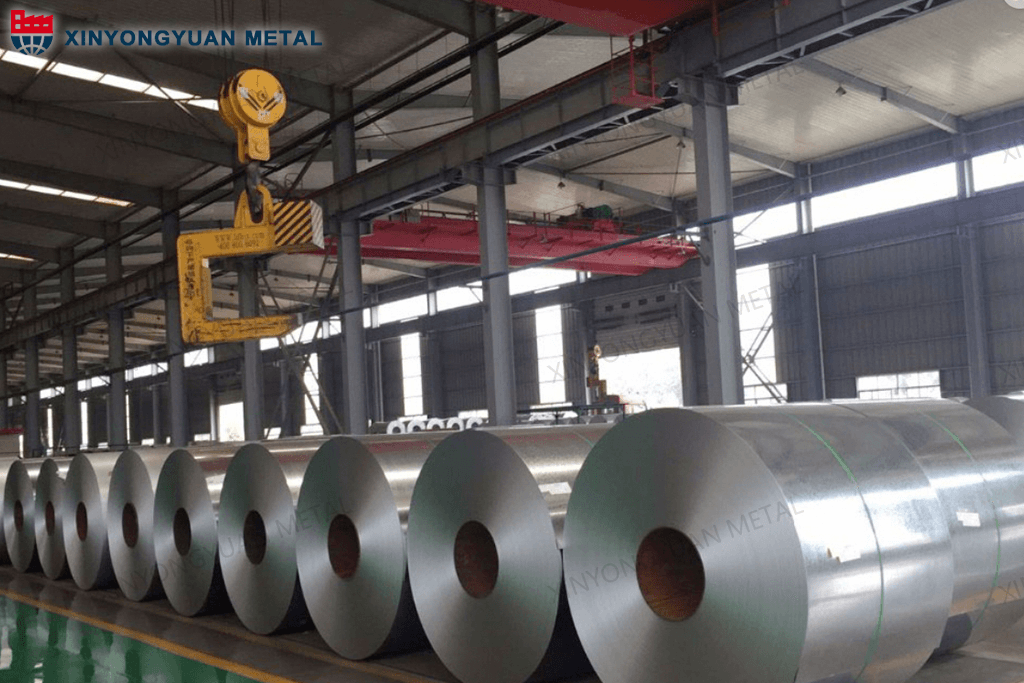

High Strength 201 Stainless Steel Coil

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

201 Stainless Steel Coil Description

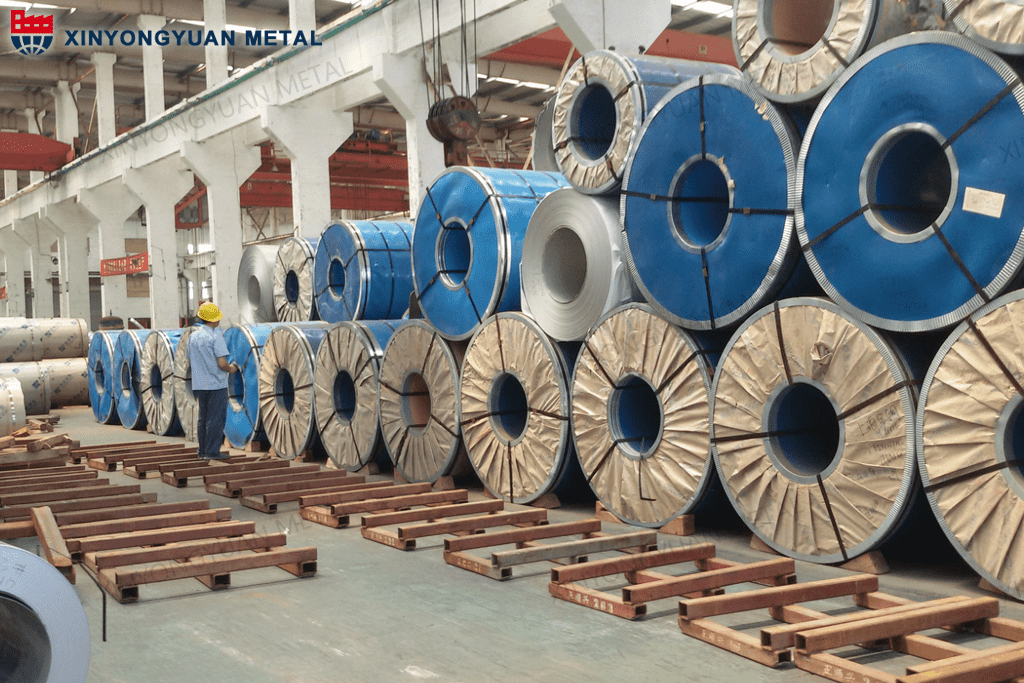

The 201 stainless steel coil is primarily composed of iron, with approximately 18% chromium and less than 0.15% carbon. It also contains small amounts of manganese, nickel, silicon, nitrogen, and copper. This grade offers higher formability compared to the 300 series grades. Additionally, it can be hardened through cold working processes but does not undergo heat treatment like the 304 or 316 grades. 201 stainless steel is characterized by its high manganese and low nickel content, providing corrosion resistance. It finds widespread use in various applications such as tabletops, countertops, kitchenware, outdoor decoration engineering, urban decoration industry, and low-grade household products. Furthermore, it is utilized in medical instruments and automotive parts that require flexibility while maintaining strength under pressure.

Product Parameters

| Product Name | 201 Stainless Steel Coil |

| Type | Steel Coil |

| Thickness | 2.5mm-10.0mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

| Width | 610mm-2000mm |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

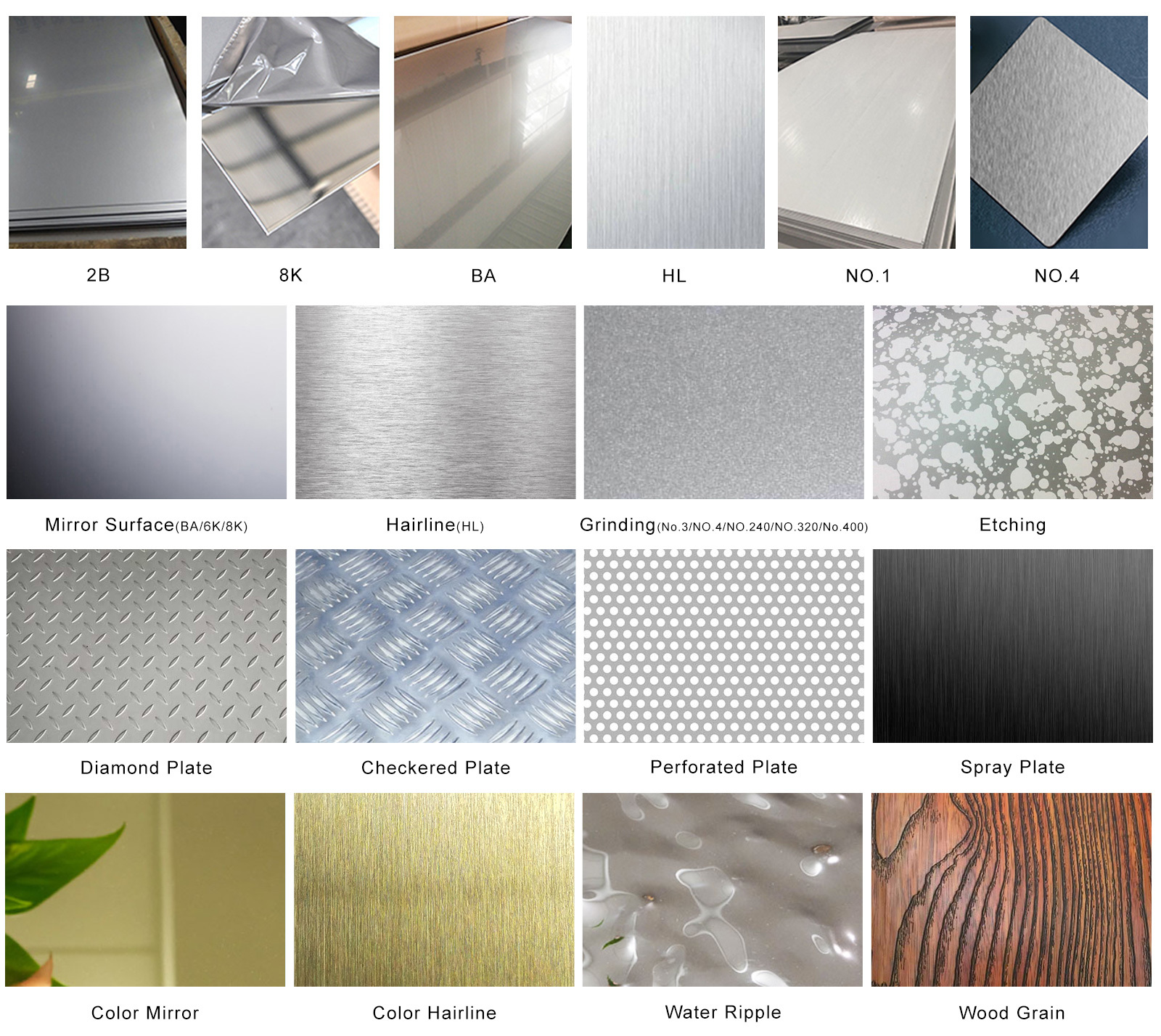

| Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

| Scope of Application | This stainless steel is extensively utilized in a wide range of industries, including high-temperature and electrical sectors, medical equipment construction, chemical and food industries, agriculture, ship parts, food and beverage packaging, kitchen supplies, trains, airplanes, conveyor belts, vehicles, as well as in bolts, nuts, springs, and screens, among others. |

| Certificate | ISO, SGS, BV, etc. |

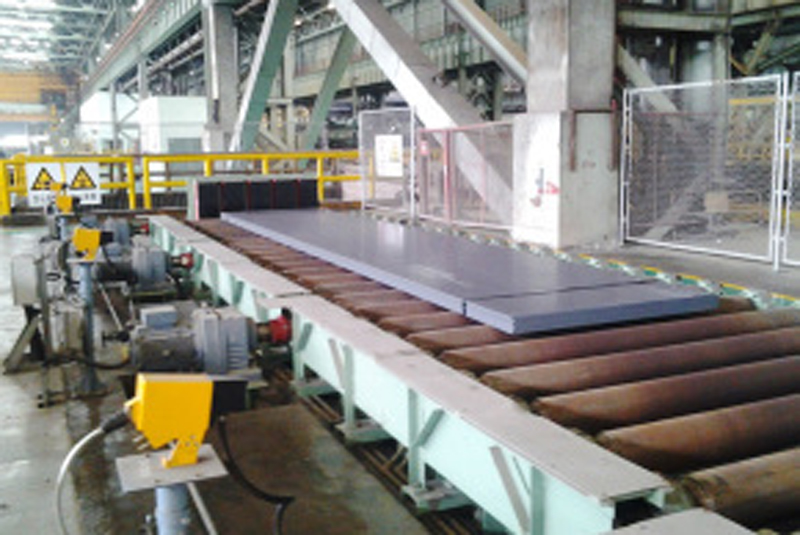

| Production Technology | Hot Rolling, Cold Rolling |

| Edge Processing | Edging, Trimming |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.15 | ≤ 0.75 | 5.50~7.50 | 16.00~18.00 | 3.50~5.50 | ≤ 0.03 | ≤ 0.06 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥ 520 | ≥ 275 | ≥55-60 | ≤183HB;≤ 100 HRB |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(μohm.in) |

| 7.8 | 197 | 15.7 | 16.2 | 27 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners