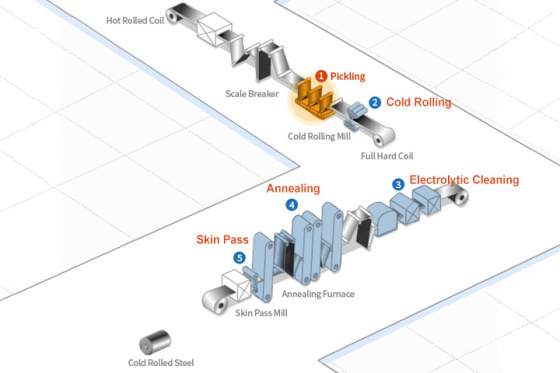

Cold Rolled Steel Production Process Details

1. Pickling: During the pickling process, hot rolled coils are passed through a pickling line where scale breaker machines and hydrochloric acid solutions are utilized to eliminate any surface scale or oxide film that may cause surface flaws during the final stage of cold rolled steel processing.

2. Cold Rolling: Pickled coils undergo cold rolling in tandem mills to achieve a specified thickness, typically 40 to 90% of the original material dimensions. This process is carried out with fully automated shape adjustment using state-of-the-art process machinery.

3. Electrolytic Cleaning: Electrolytic cleaning is employed to remove lubricant oil and contaminants from the cold rolled steel prior to the annealing process, ensuring the production of high-quality steel products.

4. Annealing: This highly productive manufacturing method enables the production of steel products with extra deep drawing qualities and high tensile strength. Two commonly used annealing methods are batch annealing and continuous annealing, each offering distinct advantages in the production process.

5. Skin Pass: The final rolling process, known as skin pass, is performed to eliminate minor surface defects such as stretch marks and to create a smooth, lustrous surface. This process results in a further thickness reduction of about 1%, ensuring the production of high-quality steel products with impeccable surface finish.

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners