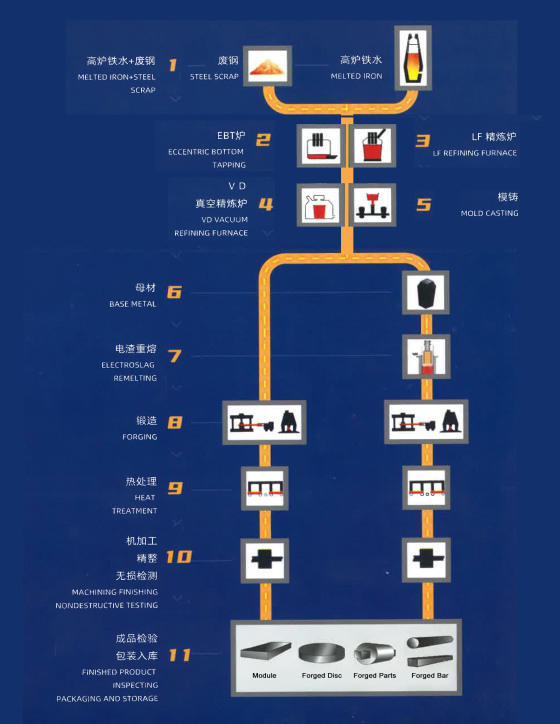

Forging Steel Production Process Introduction Diagram

1. Heating: The forging process begins with metal blocks known as “ingots,” which come in various shapes and sizes depending on the part or component to be produced. These ingots are heated to a near-molten state, allowing the metal to retain its shape while being easily manipulated with force.

2. Preforming: The heated ingot is then edged and blocked using a press or hammer to prepare it for pressing between closed dies. Edging increases the working cross-section, while blocking refines the shape in preparation for finish forging.

3. Finish Forging: The preformed metal is forced into an impression between two dies to achieve the general shape of the final product. While simple items may require only one press, more complex items may need multiple strokes at different pressures or different dies to achieve the desired design.

4. Cooling: By carefully controlling the cooling process, forgers can enhance the strength of the final product by deforming and optimizing the grain flow within the metal. An important aspect of impression die forging is the “flash,” which is the excess metal that flows outside the dies. The flash cools and hardens rapidly, becoming stronger than the metal within the dies, ensuring complete filling of any cavities.

5. Finishing: After forging, trimming and other surface treatment operations are performed to improve the dimensional accuracy of the forged product. Surface treatments can also be applied to enhance corrosion resistance and improve the appearance of the finished product.

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners