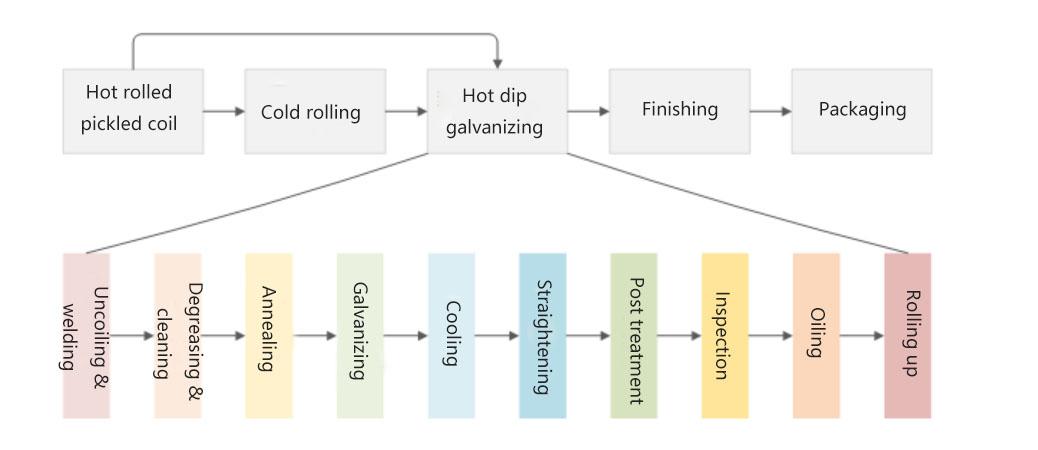

Galvanized Steels Production Process Introduction Diagram

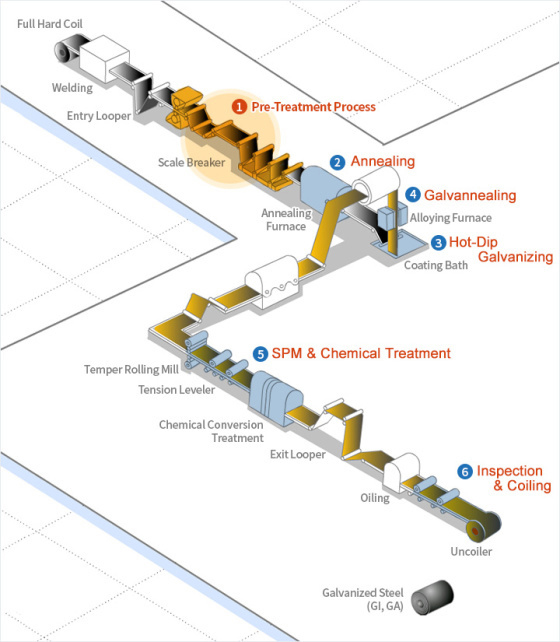

1. Pre-Treatment Process: Following the processing of cold rolled steel sheets, residual rolling oil and contaminants are effectively removed by passing the electrically charged sheet through an alkaline solution, inducing an electrochemical reaction to ensure surface cleanliness.

2. Annealing: The annealing process plays a crucial role in altering and enhancing the material properties of the pre-treated steel sheet through recrystallization, resulting in improved structural characteristics.

3. Hot-Dip Galvanizing: After passing through the annealing furnace, steel sheets are immersed in a zinc pot, where molten zinc is coated onto the surface. The desired coating weight is achieved by removing excess zinc before solidification, using high-pressure air from an air knife.

4. Galvannealing: Following the air knife process, the steel sheet surface can be coated with a zinc compound before undergoing reheating in an annealing process. This facilitates the diffusion of zinc atoms into the iron to create a Zn-Fe series alloy, enhancing the sheet’s properties.

5. SPM & Chemical Treatment: To achieve a flat surface and an elegant finish, the steel sheet undergoes processing with a skin pass mill. Additionally, to prevent the formation of white rust on the surface of activated zinc and to improve corrosion resistance, the surface is coated with a Cr-free resin.

6. Inspection & Coiling: The final steps involve thorough inspection to ensure quality standards are met, followed by coiling to prepare the steel sheets for distribution and further processing.

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners