Hot Rolled Steel Production Process Introduction Diagram

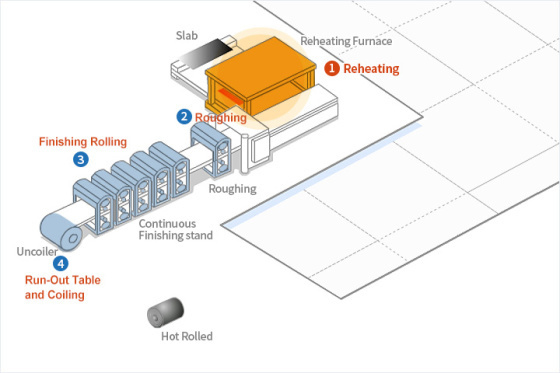

1. Reheating: After the hot rolled coils pass through a pickling line, scale breaker machines and hydrochloric acid solutions are utilized to eliminate any surface scale or oxide film, which can cause surface flaws during the final stage of cold rolled steel processing.

2. Roughing: During this process, slabs with removed surface scale are shaped into rolled materials with the appropriate thickness and width. In the entry and exit area of the roughing mill, an edger utilizes an Automatic Width Control (AWC) system to roll the strip in the width direction.

3. Finishing Rolling: The finishing rolling process aims to adjust the thickness and width of a coil to the specified dimensions, producing a smooth surface and shape at the desired finishing temperature for its intended use. Our modern equipment, including Work Roll Shift Mills, Pair Cross Mills, and On-line Roll Grinders (ORG), enhances plant productivity and improves the quality of the finished coils by controlling the crown shape.

4. Run-Out Table and Coiling: Following the finishing mill, steel strips are conveyed to the run-out table for coiling. As the strips are rolled on the table, they are cooled to the appropriate temperature for coiling by being sprayed with water.

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners