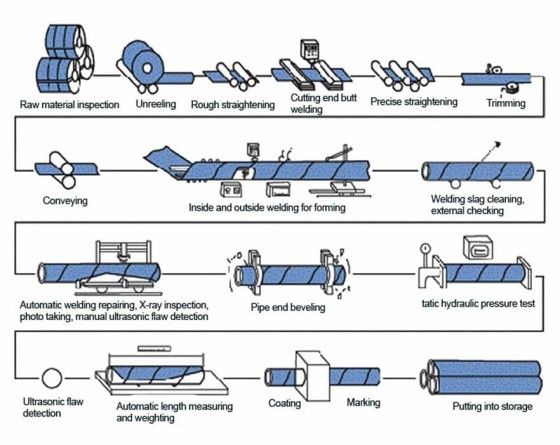

Spiral Welded Pipe (SSAW) Process Introduction Diagram

1. Steel plate preparation: We select high-quality steel plates and use advanced straightening machines to straighten them to ensure that the steel plates are flat and straight, providing a solid foundation for subsequent forming and welding processes.

2. Forming: A precision forming machine guides the steel plate through multiple passes of forming rollers, gradually forming it into a pipe. Controlling the spacing and speed of the rollers during this process is critical to ensuring accuracy of pipe diameter and wall thickness.

3. Welding: Use advanced submerged arc welding machines and double-sided welding machines to weld the inner and outer sides of the pipe. Special equipment and automatic tracking systems ensure welding quality throughout the entire process.

4. Pipe Cutting: After welding, plasma technology is used to accurately cut the pipe to the specified size to ensure accuracy and uniformity.

5. Inspection: Adopt advanced technologies such as ultrasonic flaw detectors and X-ray flaw detection equipment to conduct comprehensive inspections to ensure the quality of welds. Any defects are immediately addressed through repair and welding until each welded pipe meets the required standards.

6. Surface treatment: The spiral welded pipe is thoroughly cleaned to remove oil stains and impurities, and then sprayed with spray equipment for anti-corrosion treatment to provide long-term and effective protection. These meticulous processes produce high-quality spiral welded pipes.

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

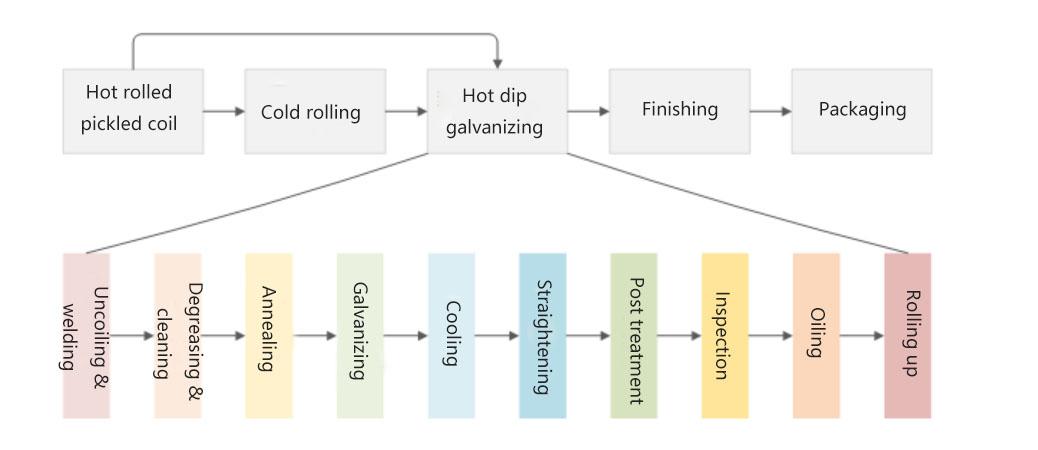

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners