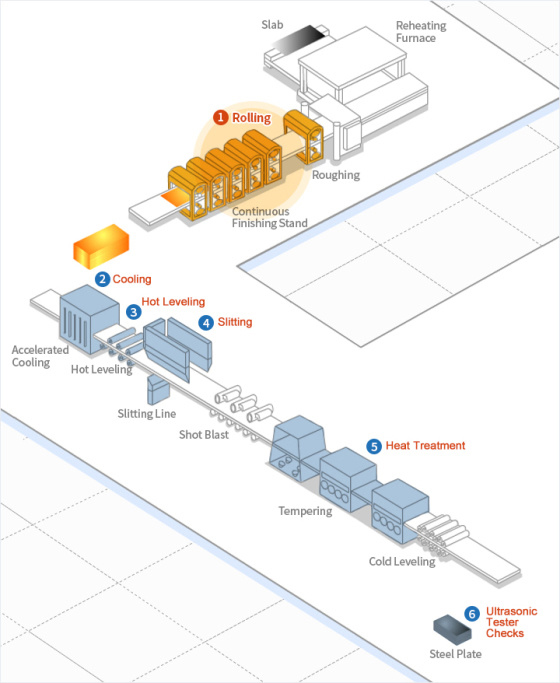

Steel Plate Production Process Introduction Diagram

1. Rolling: Our 4-high reversible finishing mill, with a maximum load of 7000 tons, ensures minimal internal defects even in thick plates. The implementation of automatic gauge control and shape control systems not only reduces thickness deviation but also enhances plate flatness, ensuring superior quality.

2. Cooling: Our advanced cooling system enables the production of high-strength steel without the need for heat treatment, achieved through rolling and accelerated cooling. Utilizing the mist cooling method with a suction type, our system boasts high cooling capacity and maintains a uniform temperature gradient in the widthwise direction, effectively reducing plate quality deviation.

3. Hot Leveling: The hot leveler is instrumental in producing superior quality flat plates by eliminating residual stress left on rolled plates, ensuring exceptional flatness and uniformity.

4. Slitting: Following the cooling process, the plates undergo meticulous dimensional accuracy inspection and are then cut into the appropriate width and length based on plate grade and thickness. This is carried out using either a mechanical shearing machine or flame planner, with production conditions tailored to factors such as the air knife gap and the nozzle size of the gas torch to achieve a higher degree of dimensional accuracy.

5. Heat Treatment: To meet the structural demands of our customers, plates undergo heat treatment after scale removal by shot blasters. Our non-oxidizing radiation tube type heat treating facilities produce scale-free heat-treated plates, ensuring the desired plate structure.

6. Ultrasonic Tester Checks: Our ultrasonic tester meticulously checks for blow holes, pipes, laminations, and other internal defects to guarantee the internal quality of plates demanded by our customers, ensuring the highest standards of quality and reliability.

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners