Wire Rods

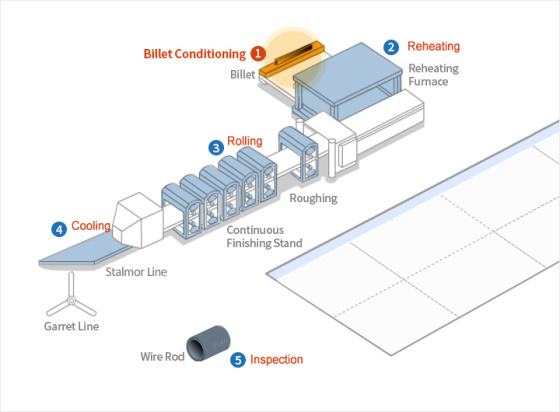

1. Billet Preparation: This process involves inspecting the surface quality of the billet and eliminating any defects. Shot blasting is utilized to remove any scale from the surface. Additionally, magnet particle testing and visual inspection are employed to identify and remove any defects using a grinder. Internal quality assurance measures such as ultrasonic testing, dimension and geometry checking are also applied.

2. Preheating: The temperature and duration of reheating within the furnace are tailored based on the intended use of the product. To prevent decarburization, which can impact the surface quality of the product, the billet is preheated adequately at a low temperature before undergoing rolling in the reheating furnace. Strict control over the fuel and air ratio is maintained for this purpose.

3. Rolling: The temperature, draft, and speed of deformation during the rolling process are managed to meet specific customer requirements for material properties. Additional measures to ensure surface quality include adjusting roll roughness and gap, detecting any cracks, and correcting dimensions.

4. Cooling: The coiling temperature at the laying head, the air flow and movement speed of the blower on the cooling bed, and the cooling speed of the insulation cover are meticulously controlled to ensure that the product possesses the necessary features for each application. High carbon steel wire rods undergo rapid cooling to achieve the required microstructure for successful drawing, while low carbon steel undergoes slow cooling to ensure the desired softness, eliminating the need for an annealing process.

5. Inspection: Samples are extracted from the front and rear edges of the product after rolling and cooling for testing to identify any defects in dimension, surface, or material integrity. Additionally, packaging and tagging are inspected in accordance with customer requirements prior to shipping.

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners