What Will Affect the Quality of Coated Steel?

| Paint Types | Hardness | Bending performance | Corrosion resistance | Weather resistance | Cost |

| PE | Excellent | Good | Good | Great | Low |

| SMP | Good | Medium | Great | Excellent | Medium |

| HDP | Good | Excellent | Great | Excellent | Medium |

| PVDF | Medium | Excellent | Excellent | Excellent | High |

As shown in the table, PVDF is the most expensive, but its service life is more than 20 years. You can choose according to the use environment and the expected service life.

When choosing the top paint, you need to pay attention to its color, color difference, gloss, hardness, durability, thickness, and other properties. While the back coating is usually determined by the use purposes and use environment. For example, if the pre-painted sheets are used in sandwich panels, choose PE or epoxy resin with good adhesion.

4. Paint Thickness

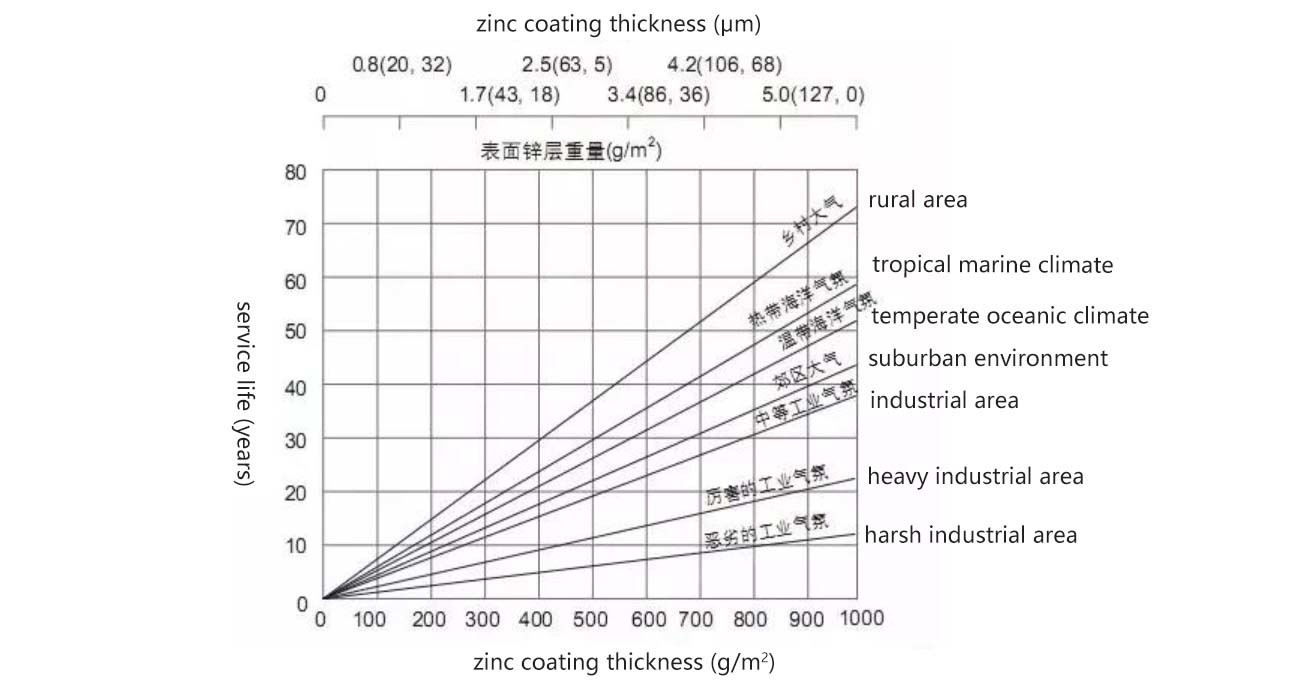

The paint also plays an anti-corrosion effect. However, because the paint film is porous, the water in the air will still penetrate into the paint and may cause the painting to peel off. For steel sheets, the GI or GL coating has a greater impact on the service life. The recommended top paint thickness is 20 μm or more.

This is a paragraph

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

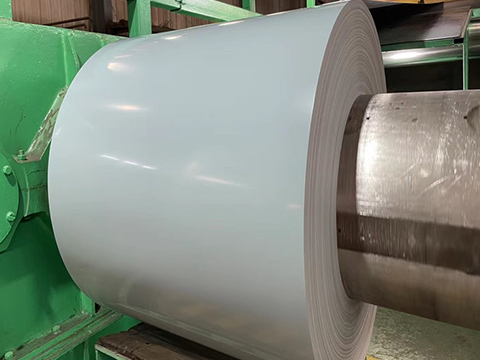

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

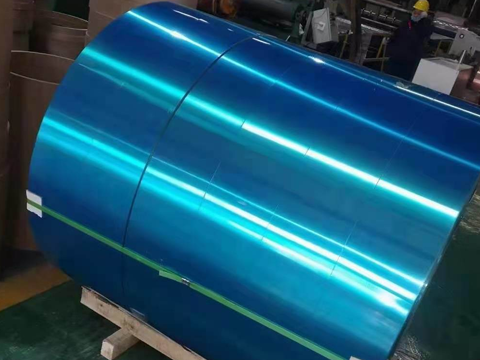

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners