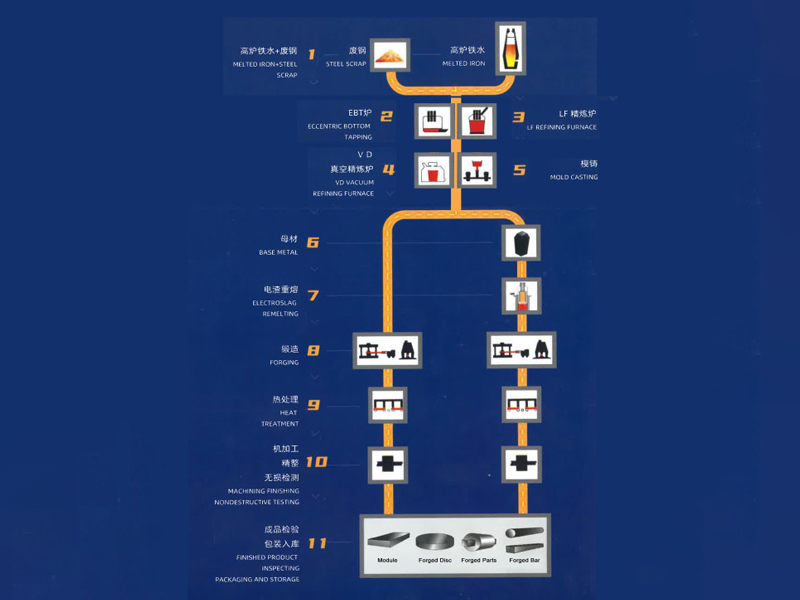

Forging Steel Production Process Introduction Diagram

1. Heating: The forging process begins with metal blocks known as “ingots,” which come in various shapes and sizes depending on the part or component to be produced. These ingots are heated to a near-molten state, allowing the metal to retain its shape while being easily manipulated with force.

2. Preforming: The heated ingot is then edged and blocked using a press or hammer to prepare it for pressing between closed dies. Edging increases the working cross-section, while blocking refines the shape in preparation for finish forging.

3. Finish Forging: The preformed metal is forced into an impression between two dies to achieve the general shape of the final product. While simple items may require only one press, more complex items may need multiple strokes at different pressures or different dies to achieve the desired design.

4. Cooling: By carefully controlling the cooling process, forgers can enhance the strength of the final product by deforming and optimizing the grain flow within the metal. An important aspect of impression die forging is the “flash,” which is the excess metal that flows outside the dies. The flash cools and hardens rapidly, becoming stronger than the metal within the dies, ensuring complete filling of any cavities.

5. Finishing: After forging, trimming and other surface treatment operations are performed to improve the dimensional accuracy of the forged product. Surface treatments can also be applied to enhance corrosion resistance and improve the appearance of the finished product.

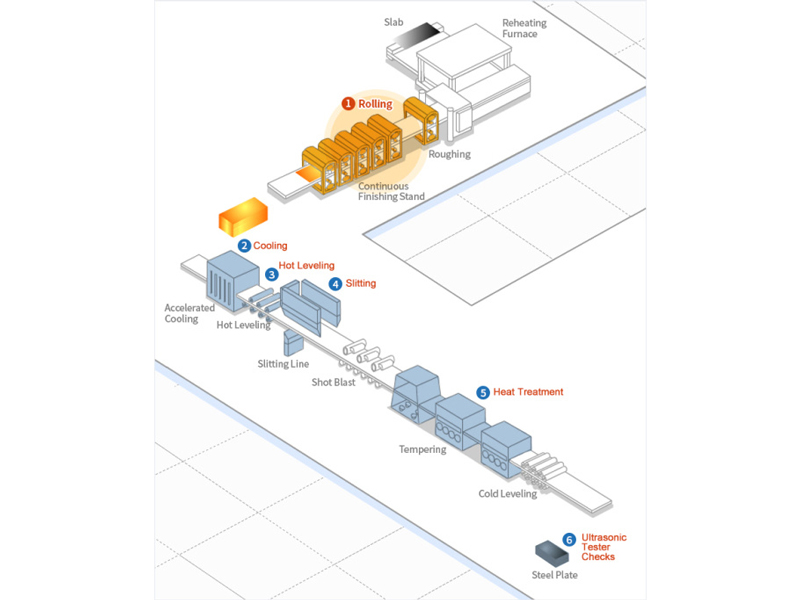

Steel Plate Production Process Introduction Diagram

1. Rolling: Our 4-high reversible finishing mill, with a maximum load of 7000 tons, ensures minimal internal defects even in thick plates. The implementation of automatic gauge control and shape control systems not only reduces thickness deviation but also enhances plate flatness, ensuring superior quality.

2. Cooling: Our advanced cooling system enables the production of high-strength steel without the need for heat treatment, achieved through rolling and accelerated cooling. Utilizing the mist cooling method with a suction type, our system boasts high cooling capacity and maintains a uniform temperature gradient in the widthwise direction, effectively reducing plate quality deviation.

3. Hot Leveling: The hot leveler is instrumental in producing superior quality flat plates by eliminating residual stress left on rolled plates, ensuring exceptional flatness and uniformity.

4. Slitting: Following the cooling process, the plates undergo meticulous dimensional accuracy inspection and are then cut into the appropriate width and length based on plate grade and thickness. This is carried out using either a mechanical shearing machine or flame planner, with production conditions tailored to factors such as the air knife gap and the nozzle size of the gas torch to achieve a higher degree of dimensional accuracy.

5. Heat Treatment: To meet the structural demands of our customers, plates undergo heat treatment after scale removal by shot blasters. Our non-oxidizing radiation tube type heat treating facilities produce scale-free heat-treated plates, ensuring the desired plate structure.

6. Ultrasonic Tester Checks: Our ultrasonic tester meticulously checks for blow holes, pipes, laminations, and other internal defects to guarantee the internal quality of plates demanded by our customers, ensuring the highest standards of quality and reliability.

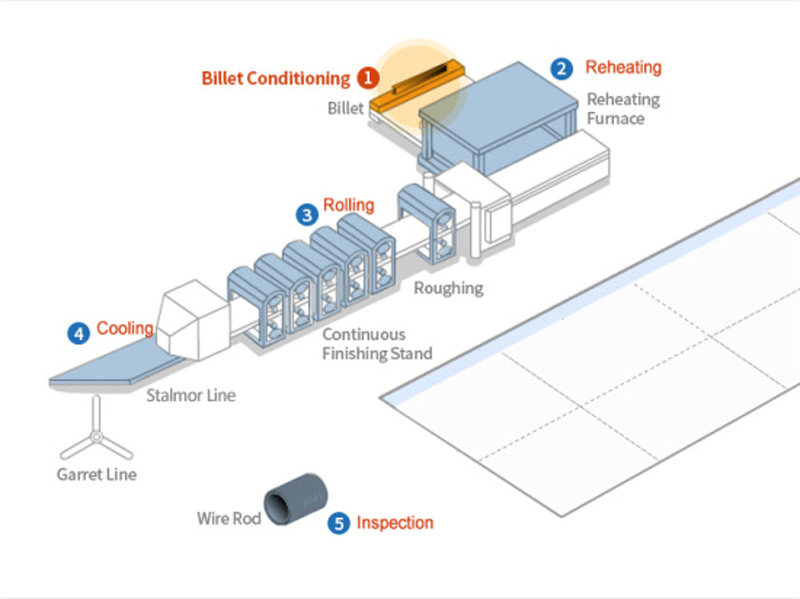

Wire Rod Production Process Introduction Diagram

1. Billet Conditioning: This important process involves a thorough inspection of the surface quality of the billet and removal of any defects. Shot peening is used to remove surface scale, while magnetic particle testing and visual inspection help identify and resolve defects using a grinder. In addition, ultrasonic testing as well as dimensional and geometric inspections are an integral part of the internal quality assurance process.

2. Reheating: The temperature and duration of furnace reheating are customized based on the specific application of the product. To prevent decarburization from affecting surface quality, the billet is preheated at a controlled low temperature before entering the heating furnace. To achieve this, the ratio of fuel to air needs to be tightly controlled.

3. Rolling: Accurately control the temperature, draft force, and deformation speed during the rolling process to meet customer requirements for material performance. Other measures to ensure surface quality include adjusting roll roughness and gaps, detecting cracks and correcting dimensions.

4. Cooling: The coiling temperature of the spinning machine, the air flow and moving speed of the cooling bed fan, and the cooling speed of the insulation cover are all carefully controlled to ensure that the product meets various specifications. application. High carbon steel wire rod is cooled quickly to obtain the microstructure required for successful drawing, while low carbon steel is cooled slowly to provide the softness required by the customer, eliminating the need for an annealing process.

5. Inspection: Samples are taken from the front and rear edges of the product after rolling and cooling for testing to identify defects in size, surface, or material integrity. In addition, packaging and labels are inspected according to customer requirements before shipment.

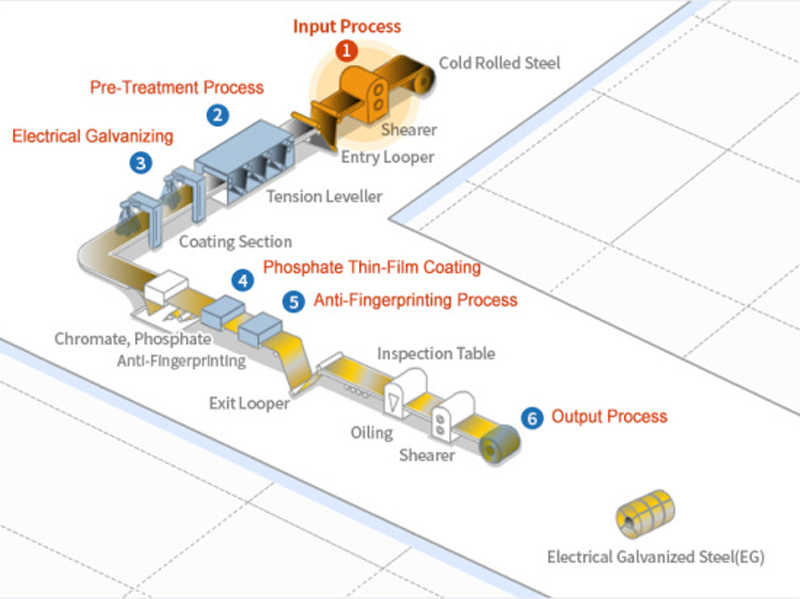

Electrical Galvanized Steels Production Process Introduction

1. Input Process: The entry point of the electrogalvanizing line is equipped with a pay-off reel, a shearing M/C, a welding M/C, a looper, and a tension leveler. The pay-off reel transports stacked or cold rolled steel materials to the shearing machine, which cuts and connects them in preparation for welding, followed by the welding process.

2. Pre-Treatment Process: An electrolytic cleaning line comprises an electrolysis tank, an acid bath, and a rinse tank to effectively remove contaminants and oxide films from the surface of the steel before electroplating, ensuring a clean and suitable surface for the subsequent processes.

3. Electrical Galvanizing: The CAROSEL method, along with other electric galvanizing techniques, involves the plating of one side at a time using a conductor roll. This process results in two-sided, single-sided, or differential-sided plated sheets. Additionally, the horizontal type allows for simultaneous plating of both sides of a sheet, producing a two-sided plated sheet.

4. Phosphate Thin-Film Coating: A phosphate thin-film is applied to the surface of the zinc layer through chemical or electrochemical reactions, providing temporary anti-corrosion protection and creating a secure painting substrate.

5. Anti-Fingerprinting Process: An organic, inorganic, or organic-inorganic hybrid film is applied to the surface of sheet steel to enhance corrosion resistance and desirable properties such as resistance to fingerprint marks and improved workability.

6. Output Process: The exit point of the line includes an output looper, tension reel, and an automatic packaging line to protect the products after coil winding, ensuring the safe and secure handling of the finished products.

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners