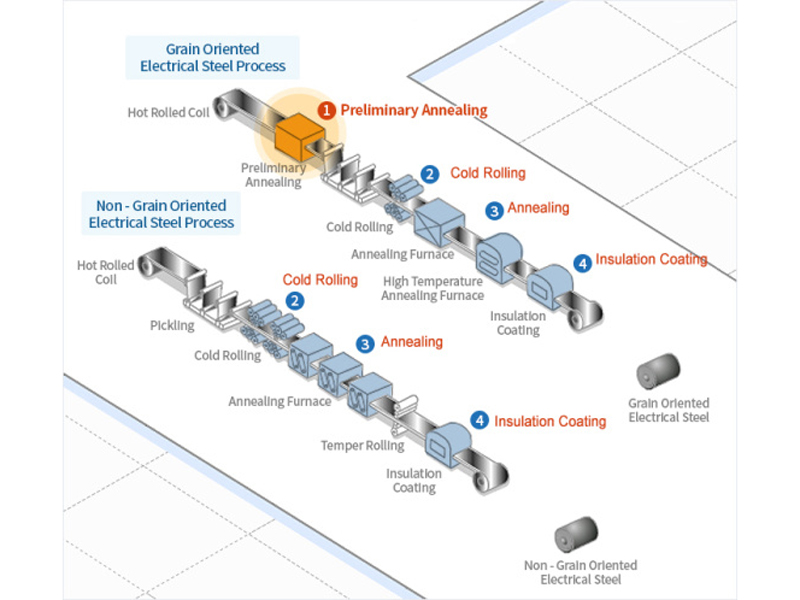

Electrical Eteel Production Process Introduction Diagram

1. Preliminary Annealing: During the preliminary annealing process, any scale formed on the hot rolled steel is effectively removed through delayed passing through a scale breaker and a hydrochloric acid bath. This initial heat treatment process not only enhances the cold rolling properties of the steel but also improves its magnetic properties.

2. Cold Rolling: To achieve specific thickness and material properties, a reduction ratio of 40-90% is typically applied. Rolling and edge trimming machines are automatically controlled to ensure uniform thickness and width.

3. Annealing: Annealing involves the transformation of cold rolled structures into a recrystallized structure through heat treatment. For grain oriented electrical steel, two distinct annealing methods are available: decarbonization annealing and high-temperature annealing. Decarbonization annealing removes excess carbon from the steel and applies a MgO coating, while high-temperature annealing produces secondary recrystallized structures with superior magnetic properties.

4. Insulation Coating: In this process, insulation coating is applied using a continuous coater roll to minimize eddy current losses, which are proportional to the sheet thickness. Multiple coaters are utilized to apply insulation coating liquid to both the top and bottom of the plate. Grain oriented electrical steel features a base coating of dark brown Forsterite (Mg2SiO4) and a transparent insulating coating containing phosphates, while non-oriented electrical steel employs various coating methods with different thicknesses and ingredients based on end usage and specific user requirements.

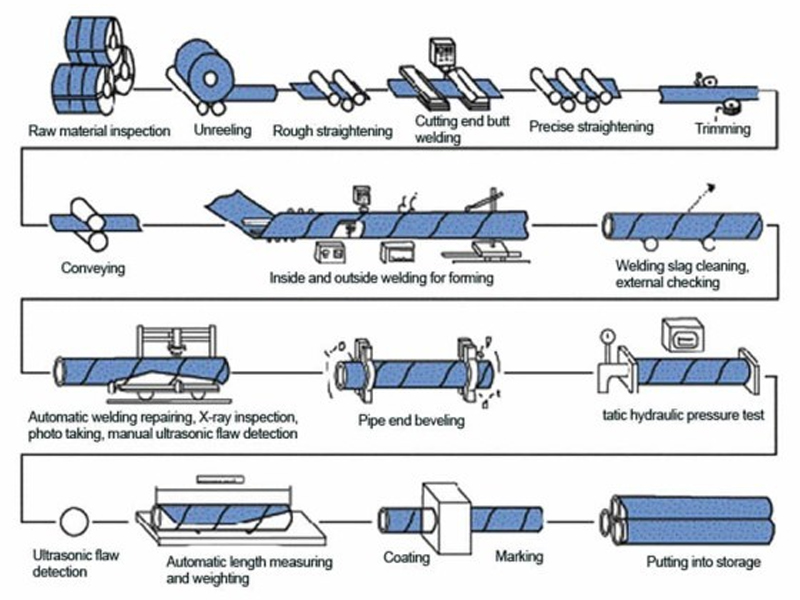

Spiral Welded Pipe (SSAW) Process Introduction Diagram

1. Steel plate preparation: We select high-quality steel plates and use advanced straightening machines to straighten them to ensure that the steel plates are flat and straight, providing a solid foundation for subsequent forming and welding processes.

2. Forming: A precision forming machine guides the steel plate through multiple passes of forming rollers, gradually forming it into a pipe. Controlling the spacing and speed of the rollers during this process is critical to ensuring accuracy of pipe diameter and wall thickness.

3. Welding: Use advanced submerged arc welding machines and double-sided welding machines to weld the inner and outer sides of the pipe. Special equipment and automatic tracking systems ensure welding quality throughout the entire process.

4. Pipe Cutting: After welding, plasma technology is used to accurately cut the pipe to the specified size to ensure accuracy and uniformity.

5. Inspection: Adopt advanced technologies such as ultrasonic flaw detectors and X-ray flaw detection equipment to conduct comprehensive inspections to ensure the quality of welds. Any defects are immediately addressed through repair and welding until each welded pipe meets the required standards.

6. Surface treatment: The spiral welded pipe is thoroughly cleaned to remove oil stains and impurities, and then sprayed with spray equipment for anti-corrosion treatment to provide long-term and effective protection. These meticulous processes produce high-quality spiral welded pipes.

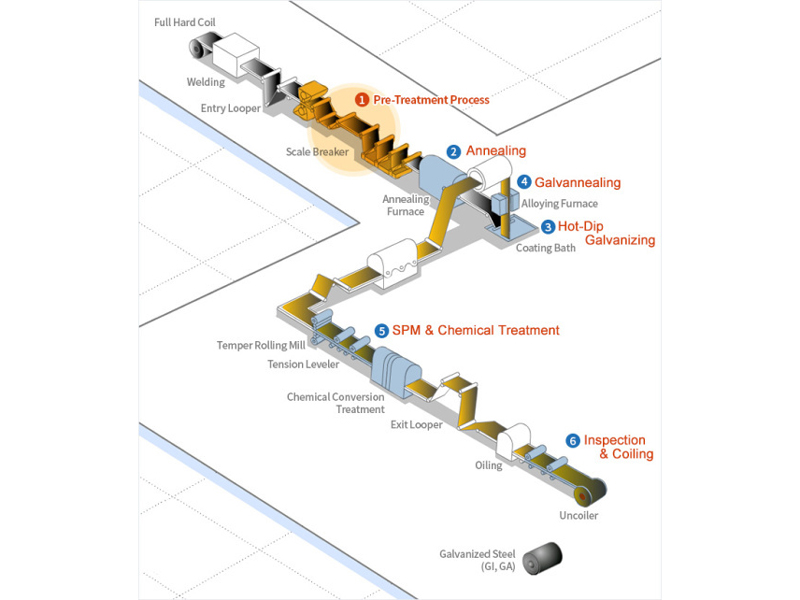

Galvanized Steels Production Process Introduction Diagram

1. Pre-Treatment Process: Following the processing of cold rolled steel sheets, residual rolling oil and contaminants are effectively removed by passing the electrically charged sheet through an alkaline solution, inducing an electrochemical reaction to ensure surface cleanliness.

2. Annealing: The annealing process plays a crucial role in altering and enhancing the material properties of the pre-treated steel sheet through recrystallization, resulting in improved structural characteristics.

3. Hot-Dip Galvanizing: After passing through the annealing furnace, steel sheets are immersed in a zinc pot, where molten zinc is coated onto the surface. The desired coating weight is achieved by removing excess zinc before solidification, using high-pressure air from an air knife.

4. Galvannealing: Following the air knife process, the steel sheet surface can be coated with a zinc compound before undergoing reheating in an annealing process. This facilitates the diffusion of zinc atoms into the iron to create a Zn-Fe series alloy, enhancing the sheet’s properties.

5. SPM & Chemical Treatment: To achieve a flat surface and an elegant finish, the steel sheet undergoes processing with a skin pass mill. Additionally, to prevent the formation of white rust on the surface of activated zinc and to improve corrosion resistance, the surface is coated with a Cr-free resin.

6. Inspection & Coiling: The final steps involve thorough inspection to ensure quality standards are met, followed by coiling to prepare the steel sheets for distribution and further processing.

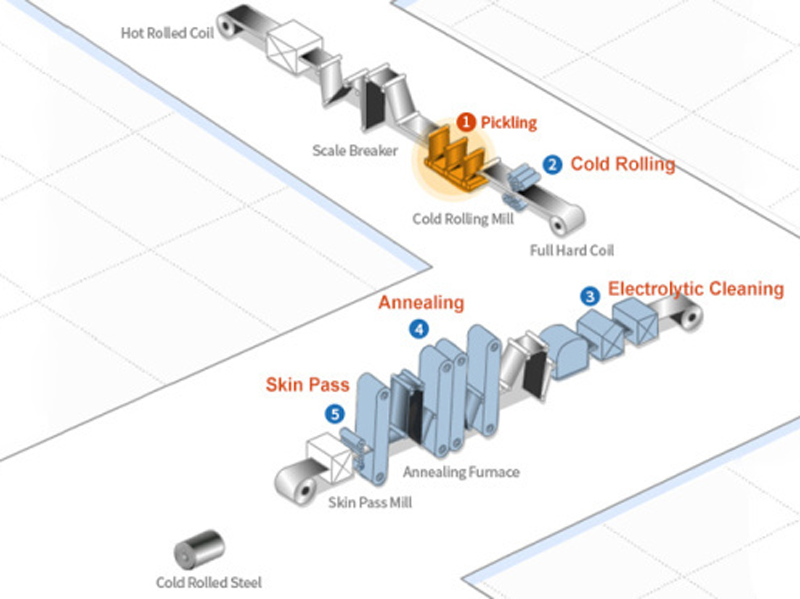

Cold Rolled Steel Production Process Details

1. Pickling: During the pickling process, hot rolled coils are passed through a pickling line where scale breaker machines and hydrochloric acid solutions are utilized to eliminate any surface scale or oxide film that may cause surface flaws during the final stage of cold rolled steel processing.

2. Cold Rolling: Pickled coils undergo cold rolling in tandem mills to achieve a specified thickness, typically 40 to 90% of the original material dimensions. This process is carried out with fully automated shape adjustment using state-of-the-art process machinery.

3. Electrolytic Cleaning: Electrolytic cleaning is employed to remove lubricant oil and contaminants from the cold rolled steel prior to the annealing process, ensuring the production of high-quality steel products.

4. Annealing: This highly productive manufacturing method enables the production of steel products with extra deep drawing qualities and high tensile strength. Two commonly used annealing methods are batch annealing and continuous annealing, each offering distinct advantages in the production process.

5. Skin Pass: The final rolling process, known as skin pass, is performed to eliminate minor surface defects such as stretch marks and to create a smooth, lustrous surface. This process results in a further thickness reduction of about 1%, ensuring the production of high-quality steel products with impeccable surface finish.

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners