PPGL Steel Sheet

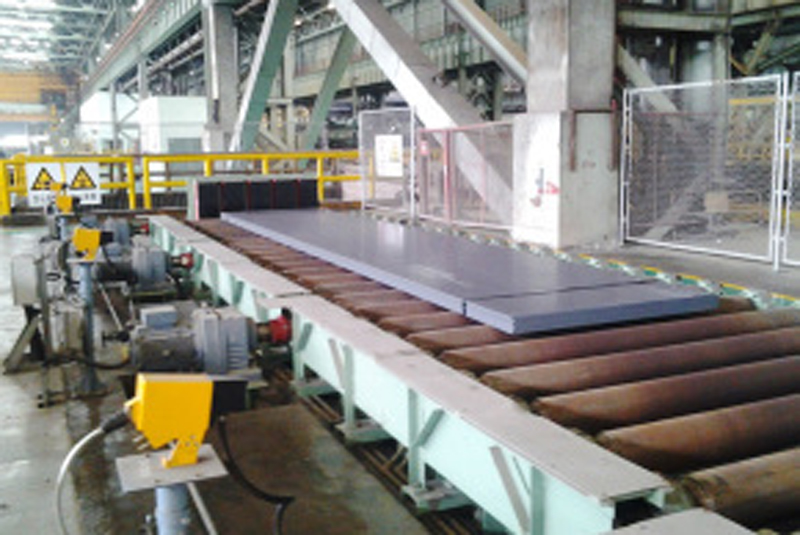

What sets PPGL apart is its unique composition. The galvalume coating is composed of 55% aluminum, 43.4% zinc and 1.6% silicon, creating a strong barrier against rust and corrosion. This advanced formula not only extends the life of the steel, but also ensures it retains its beauty over time, making it ideal for both functional and decorative applications.

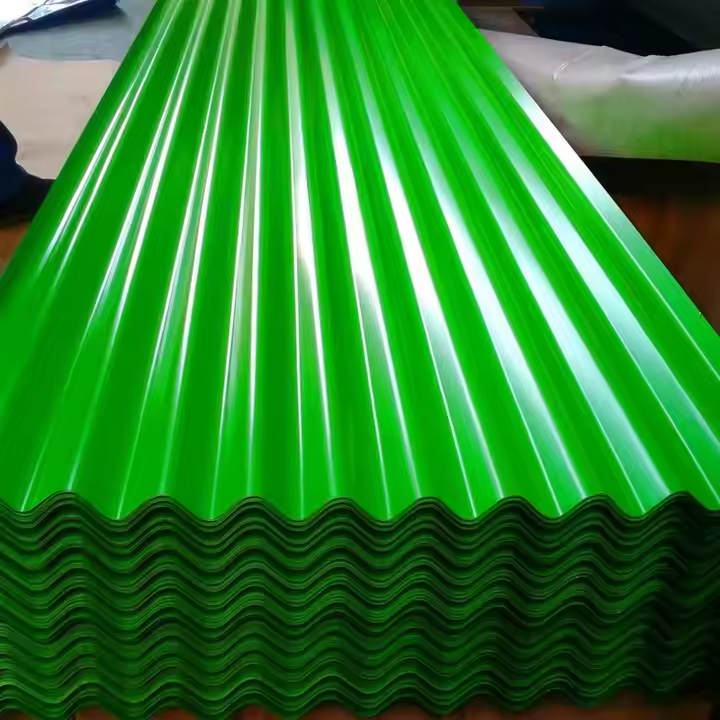

In addition to their excellent corrosion resistance, PPGL sheets also have high thermal reflectivity. This property allows them to effectively resist heat, making them suitable for a variety of environments, from hot industrial environments to residential rooftops. By reflecting solar radiation, PPGL helps maintain lower indoor temperatures, helping to improve energy efficiency and reduce cooling costs.

Product Parameters

|

Product Name |

PPGL Steel Sheet |

|

Thickness |

0.12mm-1.2mm |

|

Width |

600mm-1250mm |

|

Length |

Support Customization |

|

Color |

According RAL Color Card (Can provide custom pattern) |

|

Paint |

PE, SMP, HDP, PVDF |

|

Primer |

Epoxy primer, Polyester primer, Water soluble acrylic primer, Polyurethane primer |

|

Coating Thickness |

Top: 11-35μm, Back: 5-14μm |

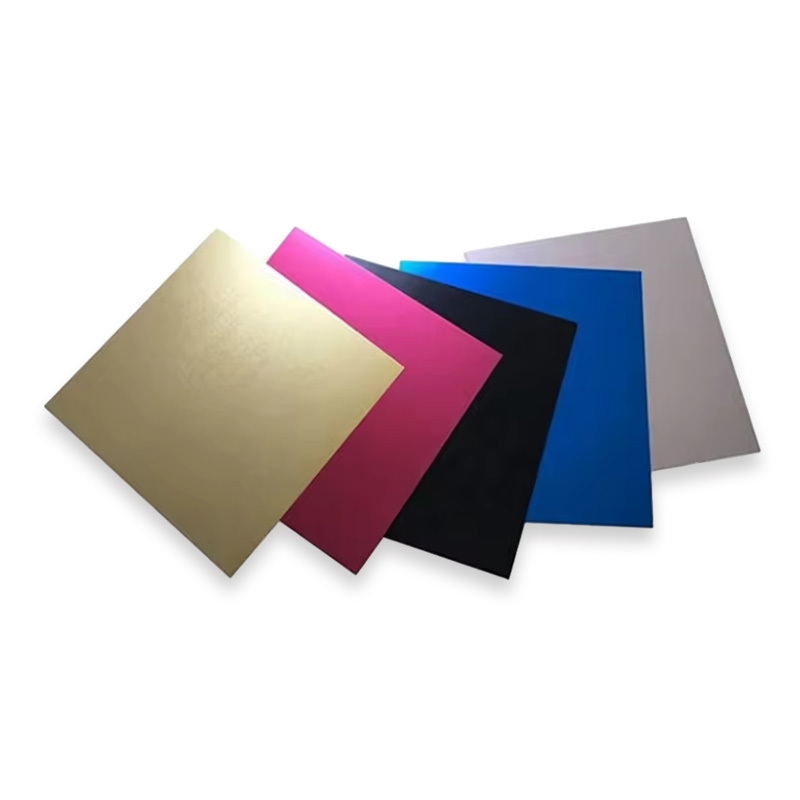

Color Selection

We provide many colors to choose from, the following are common colors, if you like other colors or patterns, please send us the RAL color code.

Advantages of Color Coated Plate

Custom Colors

You can choose any RAL color, as well as customize the pattern according to your needs. The beautiful surface makes the color coated board decorative. So it can be directly used in many fields.

Tough Soating

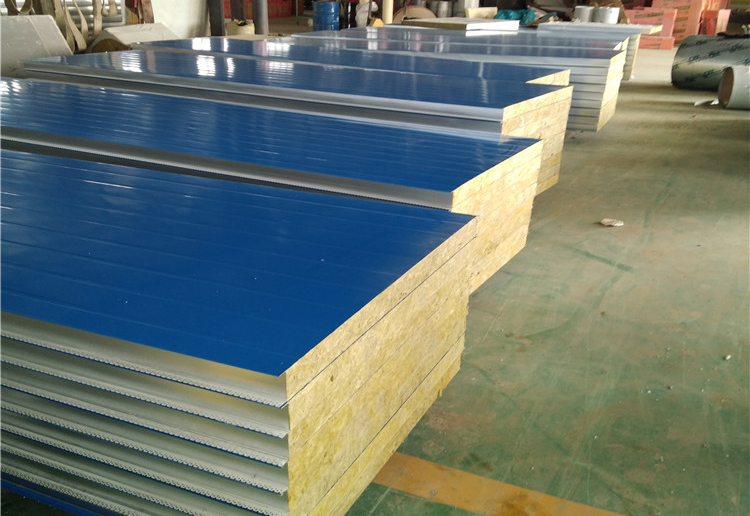

Color coated steel plate including PPGL plate PPGI steel, the use of continuous coil coating, the surface luster bright, no cracking, no peeling. In addition, it can keep the color for at least 10 years.

Excellent Mechanical Properties

The color coated plate retains the mechanical properties of the base metal, such as tensile strength. In addition, the application of the coating can protect the surface from rust, thereby extending its service life. Studies have shown that the service life of color-coated steel sheets is 50% longer than that of galvanized steel sheets.

Easy to Use

Different from the coil, the color coated plate is a kind of finished product. This means that it can be directly used in many industries. Considering its light weight, it is easy to carry and install. In addition, due to its aesthetic appearance, no additional decoration is required. Also, less maintenance is required during the service life.

Coating Type

In the coil coating, the durability of the role is the resin and pigment, the most commonly used finish polyester, silicon modified polyester, high durability polyester and polyvinylidene fluoride.

Polyester PE

Good adhesion, rich color, wide range in formability and outdoor durability, medium chemical resistance, low cost.

Silicon Modified Polyester SMP

The hardness, abrasion resistance and heat resistance of the coating film are good; as well as good external durability and powder resistance, gloss retention, general flexibility and medium cost.

High Durability Polyester HDP

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, good film adhesion, rich color, excellent cost performance.

Polyvinylidene Fluoride PVDF

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good formability, dirt resistance, limited color, and high cost.

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners