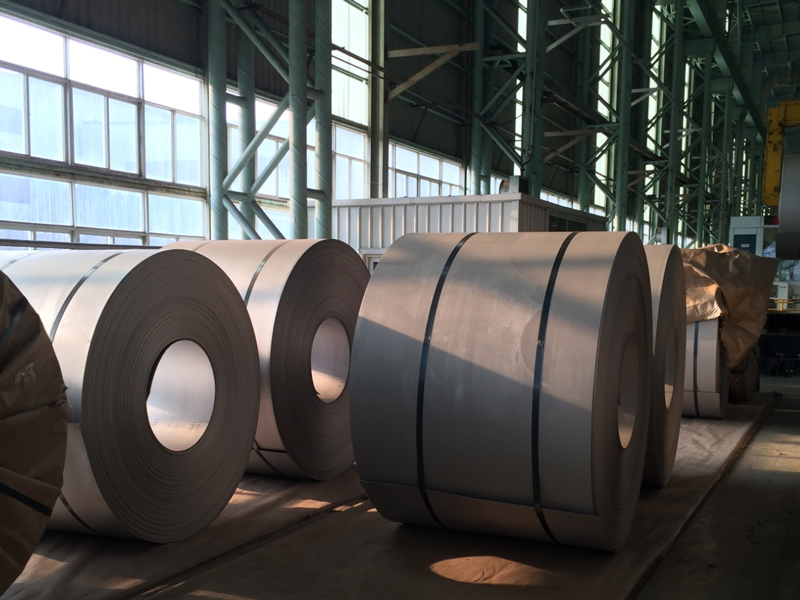

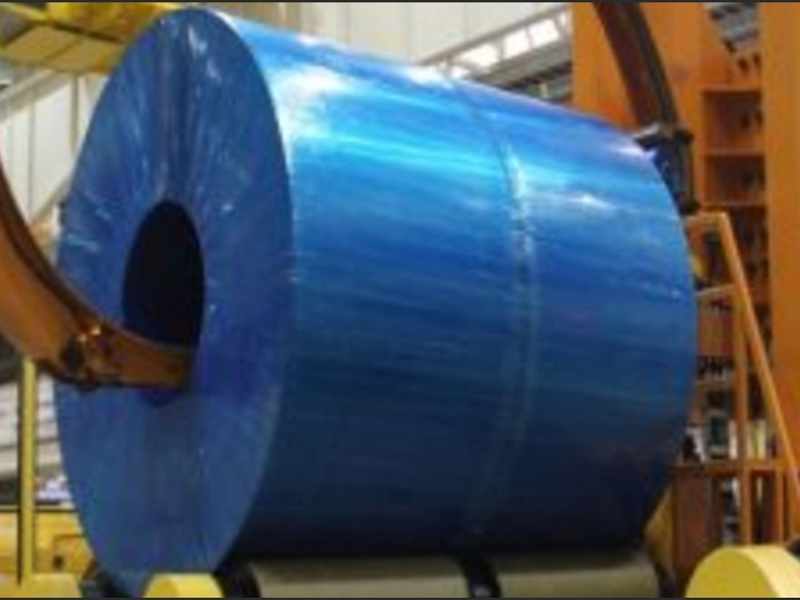

Premium Grade 1018 Cold Rolled Steel Coil

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

1018 Cold Rolled Steel Coil description

The 1018 cold rolled steel coil is crafted from a versatile, low-carbon steel with excellent case hardening properties. It is particularly well-suited for cold forming and bending operations. This type of steel is ideal for components requiring cold forming, such as crimping, swaging, or bending. 1018 steel is categorized as mild steel with medium-low carbon content. AISI 1018 carbon steel is a widely available free machining grade that, while not possessing exceptional mechanical properties, can still be easily formed, machined, welded, and fabricated.

Product Parameters

| Product Name | 1018 Cold Rolled Steel Coil |

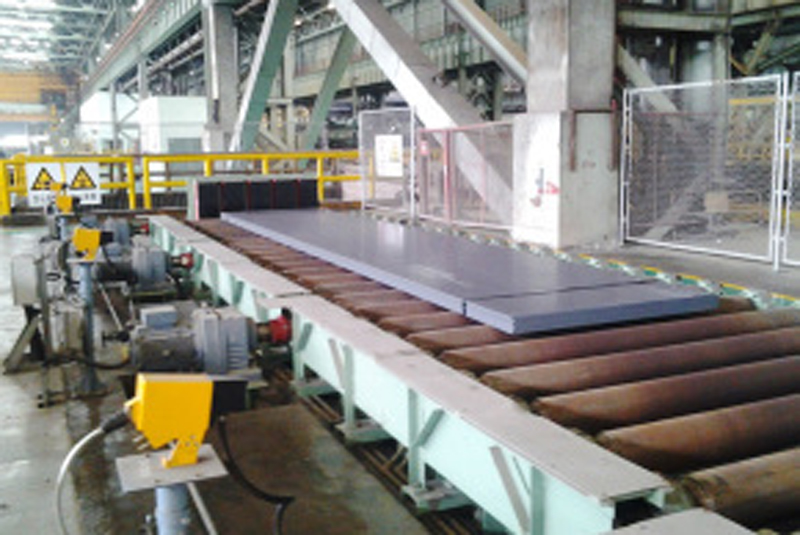

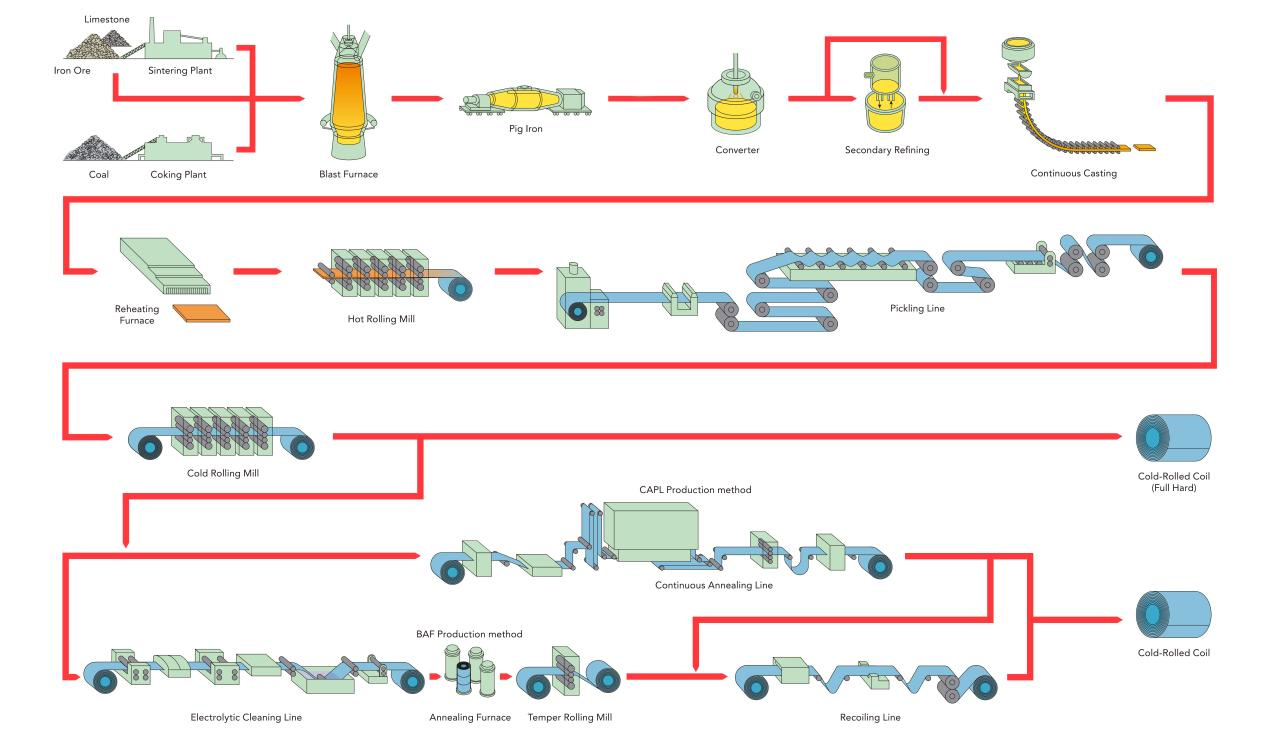

| Production Process | Hot Rolling, Cold Rolling |

| Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

| Width | 45mm-2200mm |

| Length | Custom Size |

| Thickness | Hot Rolling: 2.75mm-100mm Cold Rolling: 0.2mm-3mm |

| Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

| Surface Process | Ordinary, Wire Drawing, Laminated Film |

| Scope of Application | AISI 1018 carbon steel is commonly used in high volume screw machine parts applications. The other applications of this alloy are as follows: ● Shafts ● Spindles ● Pins ● Rods ● Sprocket assemblies. |

Chemical Composition

|

Element |

Content (%) |

|

Manganese, Mn |

0.60-0.90 |

|

Carbon, C |

0.15-0.20 |

|

Sulfur, S |

0.05 (max) |

|

Phosphorous, P |

0.04 (max) |

|

Iron, Fe |

Balance |

Mechanical Properties

|

Properties |

Metric |

Imperial |

|

Tensile strength |

440 MPa |

63800 psi |

|

Yield strength |

370 MPa |

53700 psi |

|

Modulus of elasticity |

205 GPa |

29700 ksi |

|

Shear modulus (typical for steel) |

80 GPa |

11600 ksi |

|

Poisson’s ratio |

0.29 |

0.29 |

|

Elongation at break (in 50 mm) |

15% |

15% |

|

Hardness, Brinell |

126 |

126 |

|

Hardness, Knoop (converted from Brinell hardness) |

145 |

145 |

|

Hardness, Rockwell B (converted from Brinell hardness) |

71 |

71 |

|

Hardness, Vickers (converted from Brinell hardness) |

131 |

131 |

|

Machinability (based on AISI 1212 steel. as 100 machinability) |

70 |

70 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners