Color Coated Aluminum Sheet Description

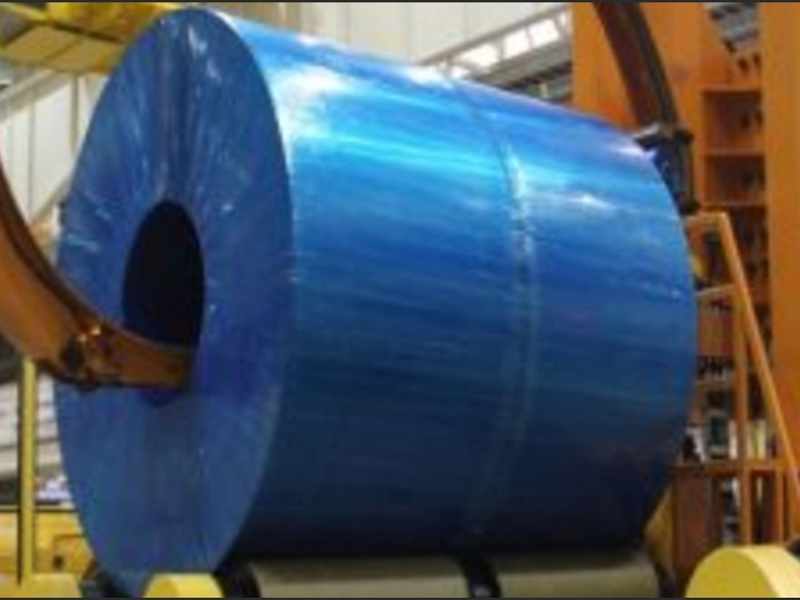

Our color coated aluminum coils are engineered to last. The advanced organic coating not only provides a stunning finish, but also offers excellent resistance to corrosion, UV rays, and weathering. This means that whether you are using them for building facades, roofing, signage, or interior applications, you can be confident that our coils will retain their brilliance and integrity for years to come.

The continuous coating process ensures a consistent layer of color across the entire surface, allowing it to blend seamlessly into any design. Available in a wide range of colors and finishes, our aluminum sheet coils can be customized to your specific aesthetic requirements, making them ideal for both commercial and residential projects.

Product Parameters

|

Product Name |

Color Coated Aluminum Sheet |

|

Thickness |

0.2mm-1.2mm |

|

Width |

600mm-1250mm |

|

Length |

750mm-1100mm |

|

Color |

According RAL Color Card (Can provide custom pattern) |

|

Shape |

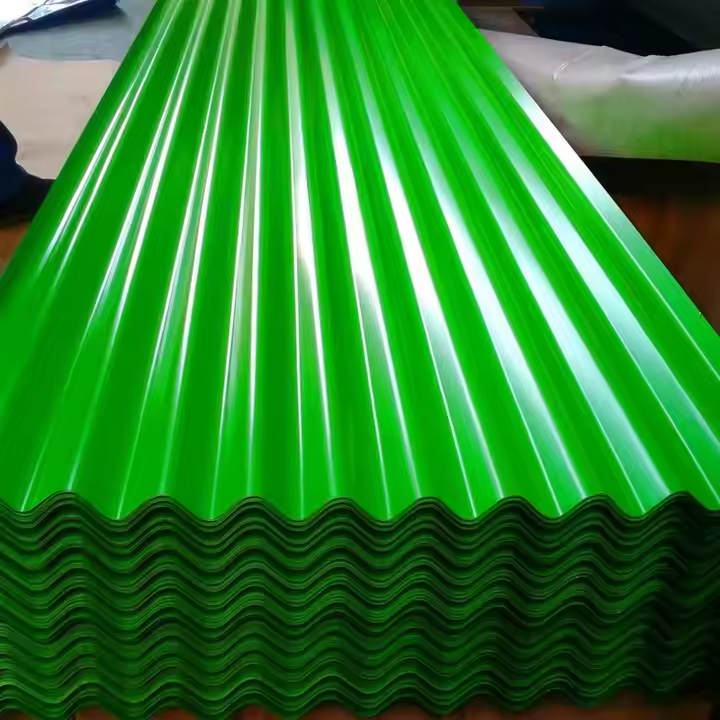

Wavy, Trapezoidal, etc. |

|

Paint |

PE, SMP, HDP, PVDF |

|

Primer |

Epoxy primer, Polyester primer, Water soluble acrylic primer, Polyurethane primer |

|

Coating Thickness |

Top: 11-35μm, Back: 5-14μm |

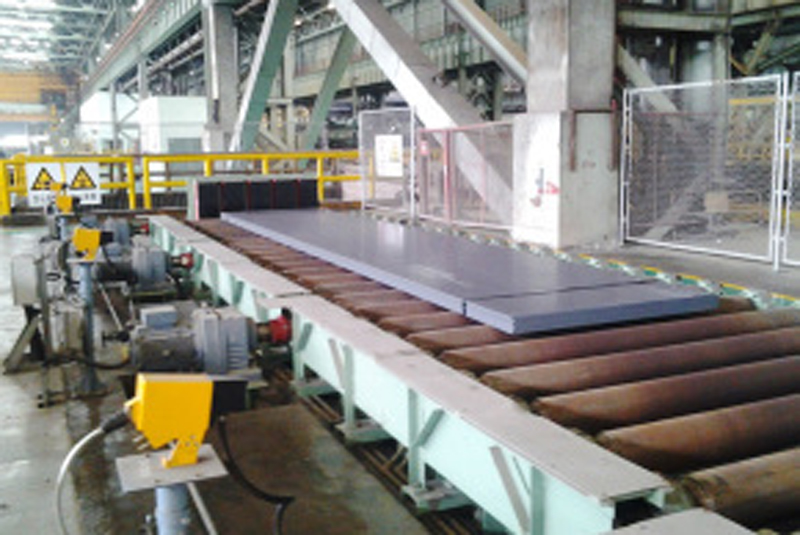

Processes of Colored Aluminum Sheets

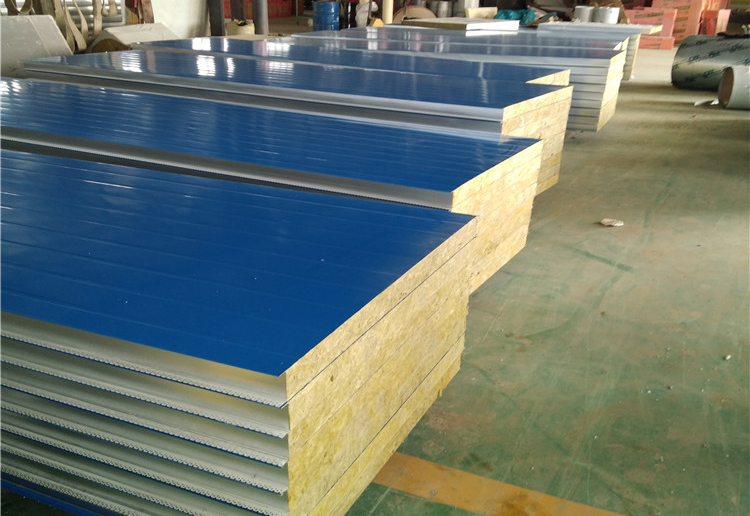

Coating: Colored aluminum sheets are coated with a colored finish using various processes, such as powder coating, anodizing, and painting. These processes add a layer of color to the surface of the aluminum sheet, improving its appearance and durability.

Cutting and Shaping: Colored aluminum sheets are cut and shaped using various processes, such as shearing, sawing, and punching. These processes help manufacturers create custom shapes and sizes of colored aluminum sheets that are suitable for various applications.

Forming: Colored aluminum sheets can be formed into different shapes using various processes, such as bending, folding, and rolling. These processes help manufacturers create colored aluminum sheets that are suitable for specific applications, such as roofing and wall cladding.

Scope of Application

Building and Construction: Colored aluminum sheets are commonly used in the building and construction industry for roofing, wall cladding, and facades. These sheets are lightweight, durable, and corrosion-resistant, making them an excellent choice for exterior applications.

Transportation: Colored aluminum sheets are used in the transportation industry for manufacturing car bodies, aircraft parts, and marine vessels. These sheets are lightweight, strong, and flexible, making them ideal for applications that require high strength and durability.

Packaging: Colored aluminum sheets are also used in the packaging industry for making cans, containers, and lids. These sheets are non-toxic, odorless, and moisture-resistant, making them an excellent choice for food and beverage packaging.

Electronics: Colored aluminum sheets are used in the electronics industry for manufacturing electronic components, such as capacitors, heat sinks, and connectors. These sheets are excellent conductors of electricity, making them ideal for applications that require high conductivity.

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners