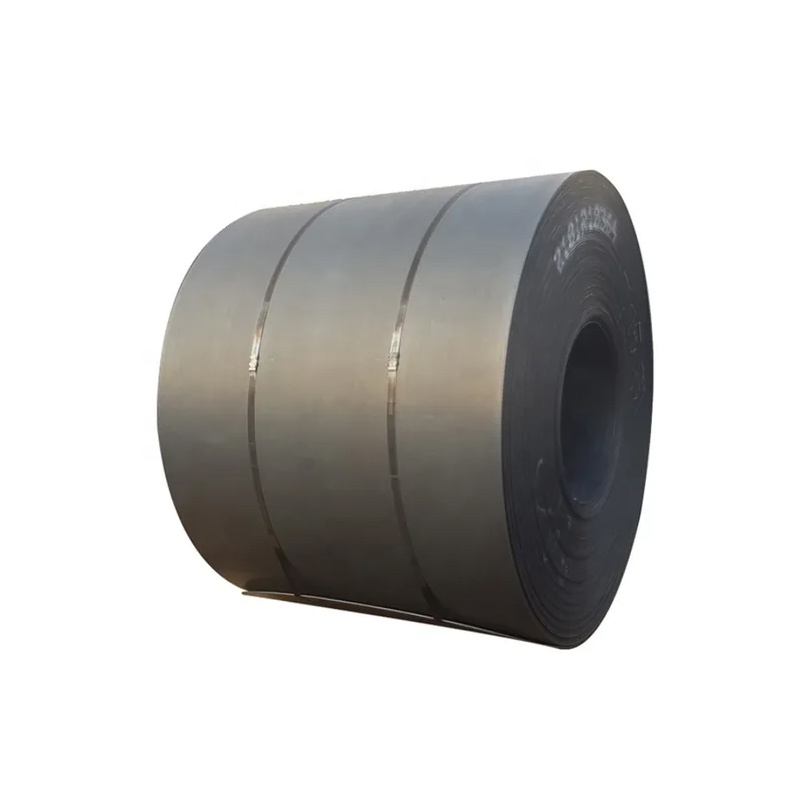

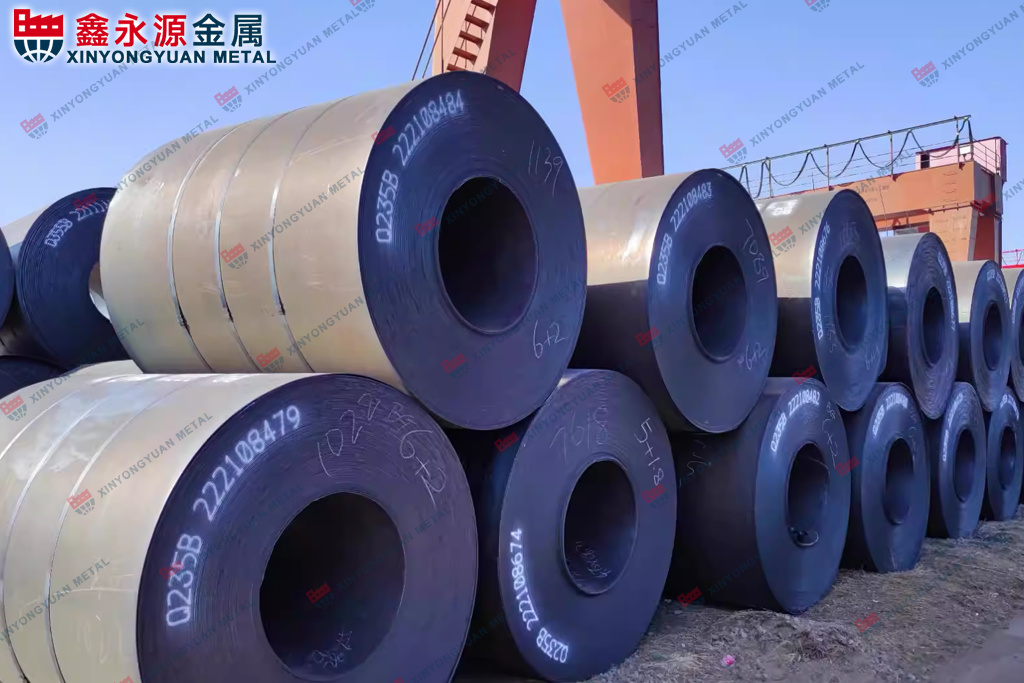

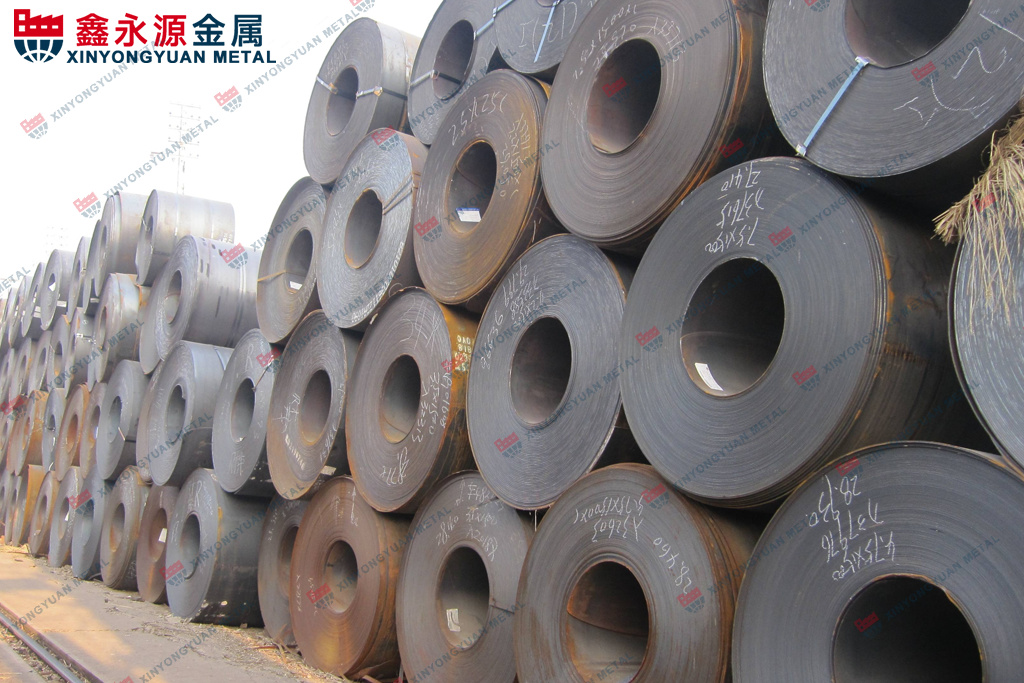

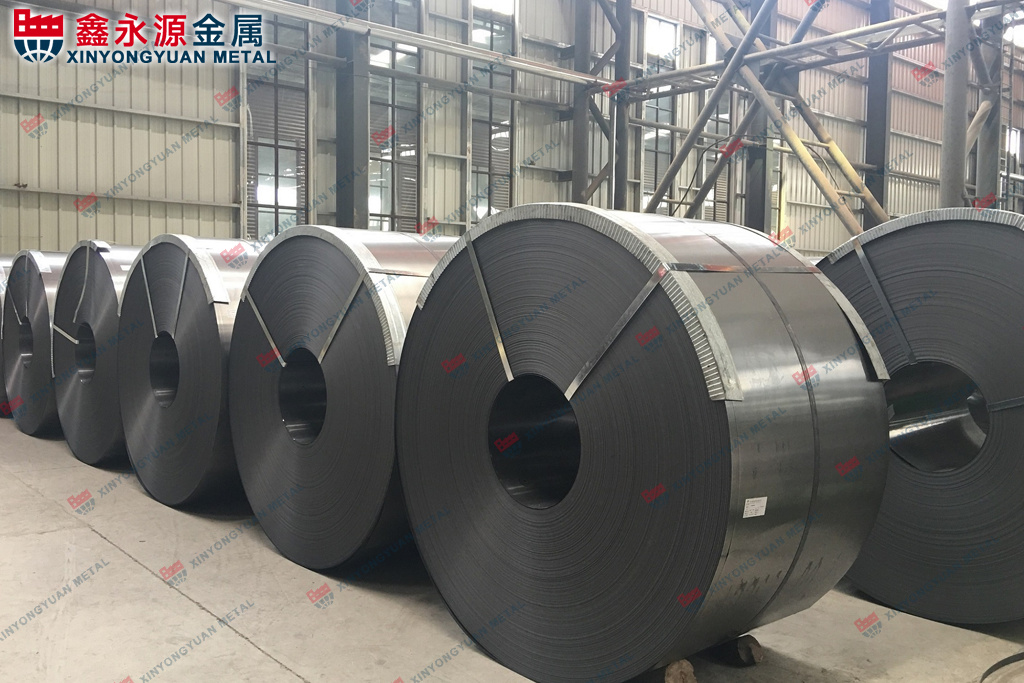

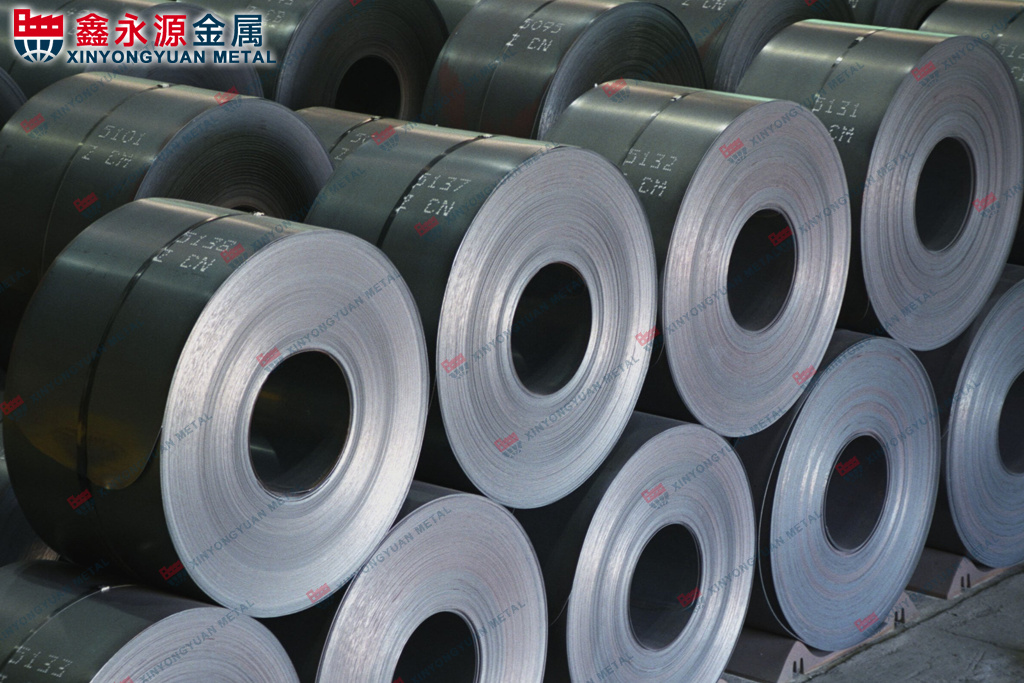

SPHC Hot Rolled Steel Coil

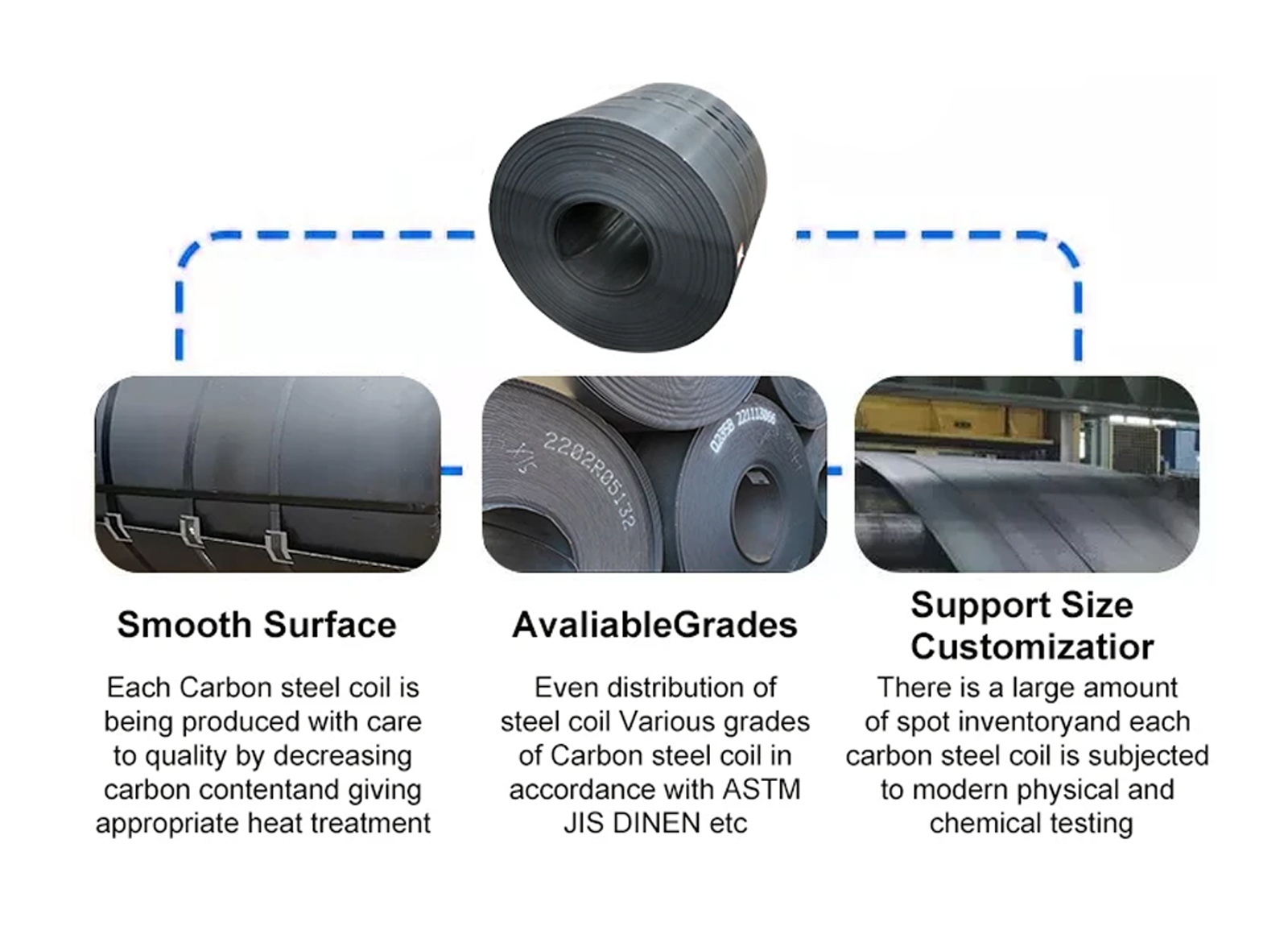

The hot rolling process involves passing steel through rollers at high temperatures, allowing it to be formed into plates or strips with great precision. This method not only improves the physical properties of the steel, but also ensures that the steel maintains its integrity under pressure. As a result, SPHC steel has excellent strength, durability and ductility, making it ideal for a variety of applications.Whether you work in automotive, construction or manufacturing, SPHC steel offers the versatility and resilience you need to tackle demanding projects. Its enhanced strength allows it to be built into sturdy structures, while its ductility ensures it can be easily formed into a variety of shapes without sacrificing quality. This combination of properties makes SPHC steel a reliable choice for everything from structural components to complex designs.In addition, SPHC steel is designed to stand the test of time. Its durability means it can withstand harsh environmental conditions, reducing the need for frequent replacement and maintenance. This not only saves costs but also contributes to a more sustainable use of materials.

Product Parameters

|

Product Name |

SPHC Hot Rolled Steel Coil |

|

Production Process |

Hot Rolling |

|

Material Standards |

AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

|

Width |

800mm-1600mm |

|

Length |

1m-1200m, or Customized Size |

|

Thickness |

0.1mm-4mm |

|

Delivery Conditions |

Rolling, Annealing, Quenching, Tempered or Standard |

|

Surface Process |

Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

|

Element |

Percentage |

|

C |

0.26 |

|

Cu |

0.2 |

|

Fe |

99 |

|

Mn |

0.75 |

|

P |

0.04 max |

|

S |

0.05 max |

Mechanical Properties

|

Imperial |

Metric |

|

|

|

Density |

0.282 lb/in3 |

7.8 g/cc |

|

|

Ultimate Tensile Strength |

58,000 psi |

400 MPa |

|

|

Yield Tensile Strength |

47,700 psi |

315 MPa |

|

|

Shear Strength |

43,500 psi |

300 MPa |

|

|

Melting Point |

2,590 - 2,670 °F |

1,420 - 1,460 °C |

|

Scope of Application

● Trailers

● Walkways

● Ramps

● Structural supports

● General fabrication

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners