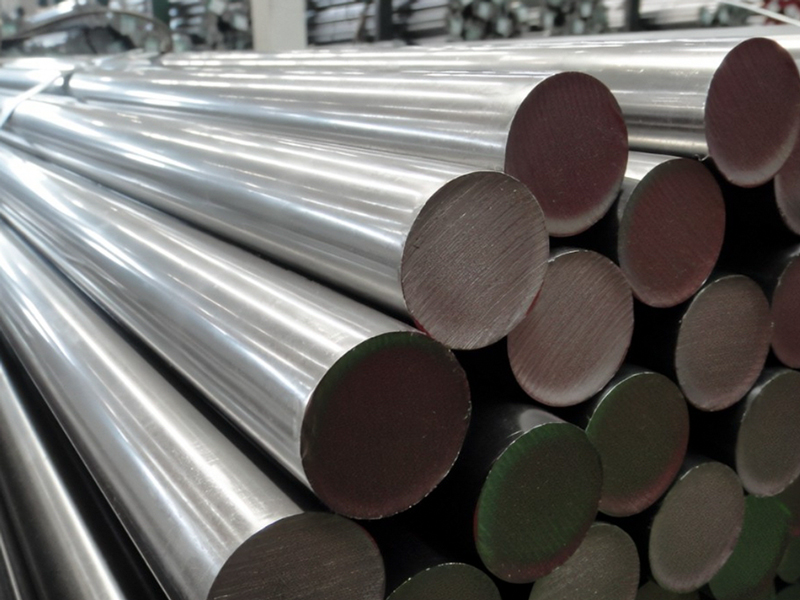

403 Stainless Steel Bar Description

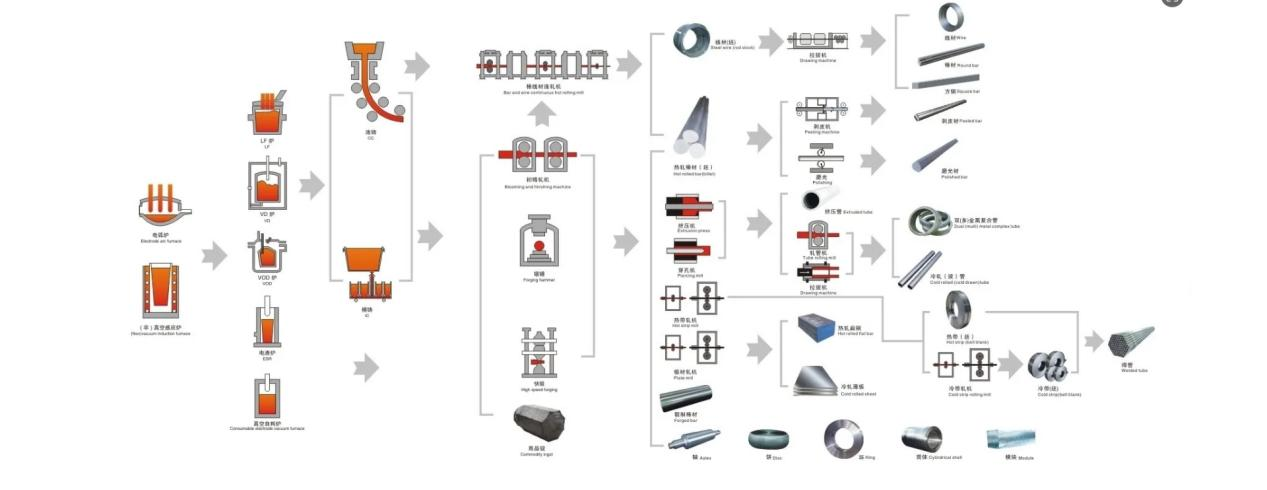

The unique composition of 403 stainless steel ensures it maintains structural integrity even in harsh conditions. Its high chromium content provides excellent resistance to oxidation and corrosion, making it suitable for use in industries such as aerospace, automotive, and manufacturing. Whether you are manufacturing components for high-pressure environments or creating complex designs that require precision, 403 stainless steel provides the performance you need.

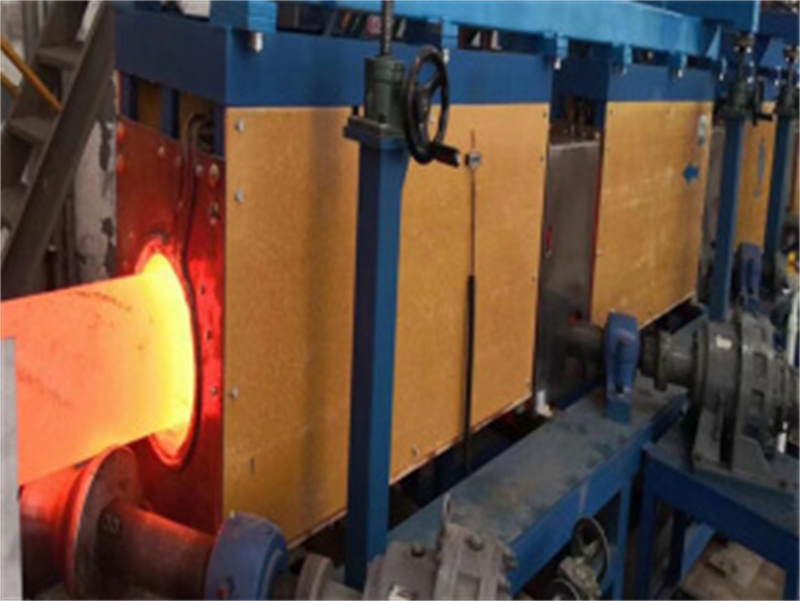

One of the outstanding features of 403 stainless steel is that it can be heat treated, which increases its hardness and strength. This property makes it a top choice for applications that require the material to withstand heavy loads and impacts. In addition, its excellent machinability makes it easy to manufacture, ensuring that you can achieve the specifications you require without compromising quality.

Product Parameters

| Product Name | 403 Stainless Steel Bar | |

| Type | Steel Bar | |

| Outer Diameter | Round Bar | 4mm-500mm |

| Hexagon Bar | 18mm-57mm (11/16″ to 2-3/4″) | |

| Square Bar | 18mm-47mm (11/16″ to 1-3/4″) | |

| Flat Steel | 1/2 "to 10", Thickness: 2mm-150mm, Can provide customized | |

| Length | 1-6 meters, Length can be customized | |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

| Surface | Black, Bright Polished, Rough Turning, Mattness Surface Treatment, No. 4. BA, etc. | |

| Scope of Application | Stainless steel bars find extensive applications across a wide range of industries, including shipbuilding, defense, automotive, textiles, paper and pulp, manufacturing, cement, heavy earthmoving equipment, and construction. | |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.15 | ≤ 0.5 | ≤ 1.0 | 11.5~13.0 | ≥ 0.6 | ≤ 0.03 | ≤ 0.04 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥485 | ≥290 | ≥25 | ≤ 98HB |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 7.80 | 190 | 9.9 | 21.5 | 740 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners