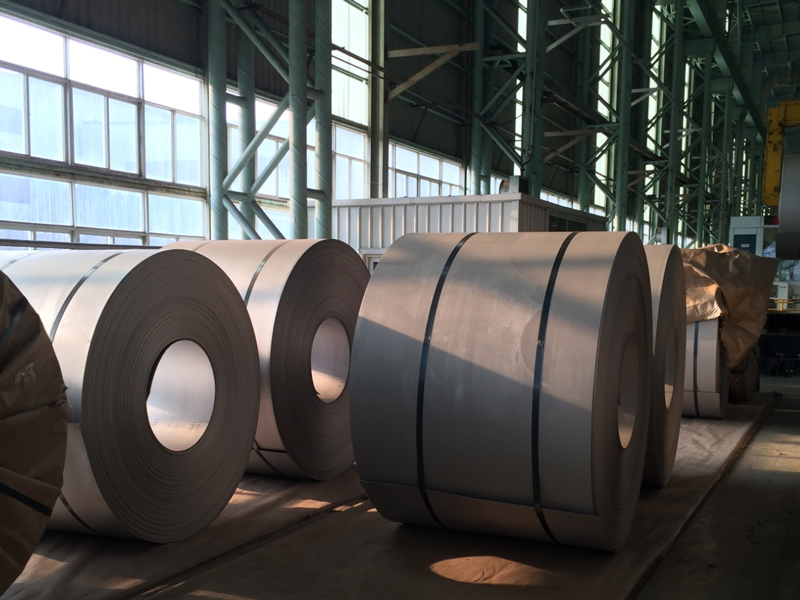

Toughened 1023 Cold Rolled Steel Coil

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

1023 Cold Rolled Steel Coil description

1023 cold rolled steel coil is crafted from low-carbon alloy steel, tailored for applications necessitating exceptional machinability and formability. This steel type offers remarkable weldability and machinability, rendering it a prime selection for diverse applications. Its composition primarily comprises iron, carbon, and manganese. Notably, 1023 steel coil exhibits lower heat resistance compared to other steels due to its low carbon content. Therefore, it is not recommended for high-temperature operations unless appropriate heat treatments such as tempering or annealing are applied beforehand.

Product Parameters

| Product Name | 1023 Cold Rolled Steel Coil |

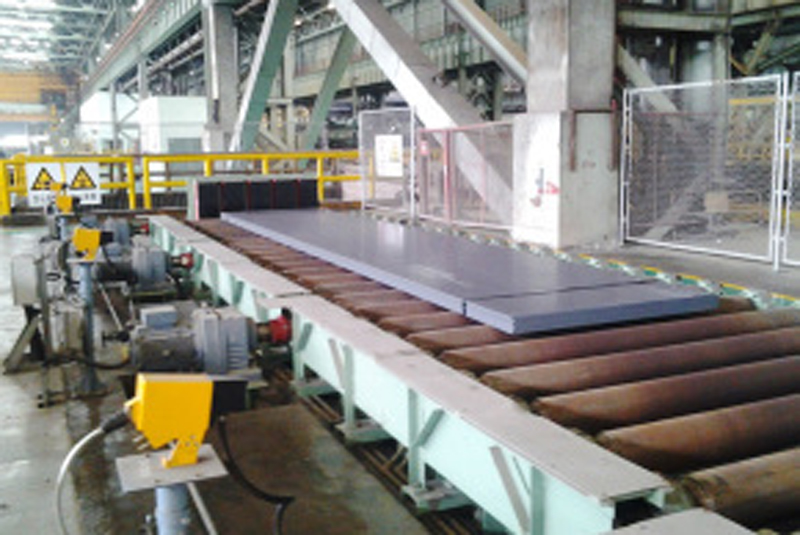

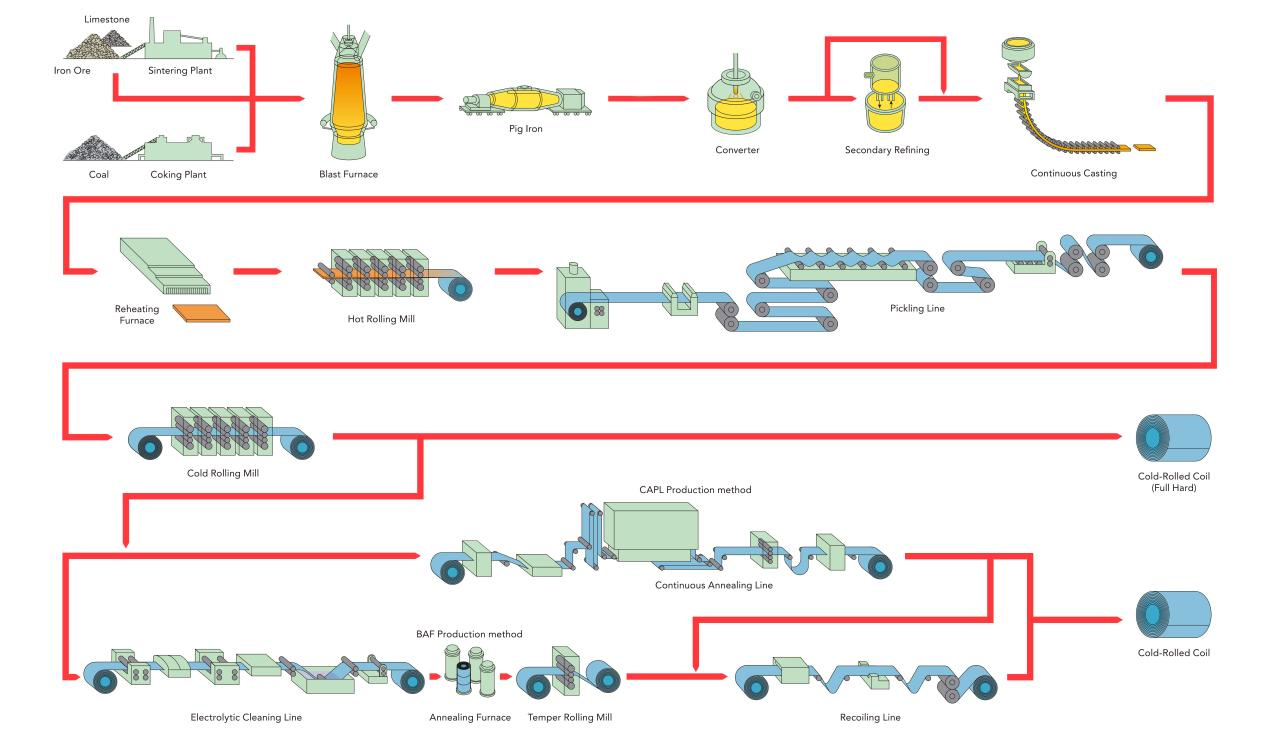

| Production Process | Hot Rolling, Cold Rolling |

| Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

| Width | 45mm-2200mm |

| Length | Custom Size |

| Thickness | Hot Rolling: 2.75mm-100mm Cold Rolling: 0.2mm-3mm |

| Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

| Surface Process | Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

| Element | Content (%) |

| Iron, Fe | 99.06-99.51 |

| Manganese. Mn | 0.30-0.60 |

| Carbon, C | 0.19-0.25 |

| Sulfur, S | ≤ 0.050 |

| Phosphorous, P | ≤ 0.040 |

Mechanical Properties

| Mechanical Properties | Metric | Imperial |

| Tensile strength | 425 MPa | 61600 psi |

| Yield strength | 360 MPa | 52200 psi |

| Shear modulus | 80.0 GPa | 11600 ksi |

| Bulk modulus | 140 GPa | 20300 ksi |

| Elastic modulus | 190-210 GPa | 27557-30458 ksi |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

| Elongation at break | 15% | 15% |

| Reduction of area | 40% | 40% |

| Hardness Brinell | 121 | 121 |

| Hardness, Knoop | 140 | 140 |

| Hardness, Rockwell B | 68 | 68 |

| Hardness, Vickers | 126 | 126 |

| Machinability | 65 | 65 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners