Wear Resistant AISI/SAE 4130 Alloy Steel Bar

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

AISI/SAE 4130 Alloy Steel Bar Description

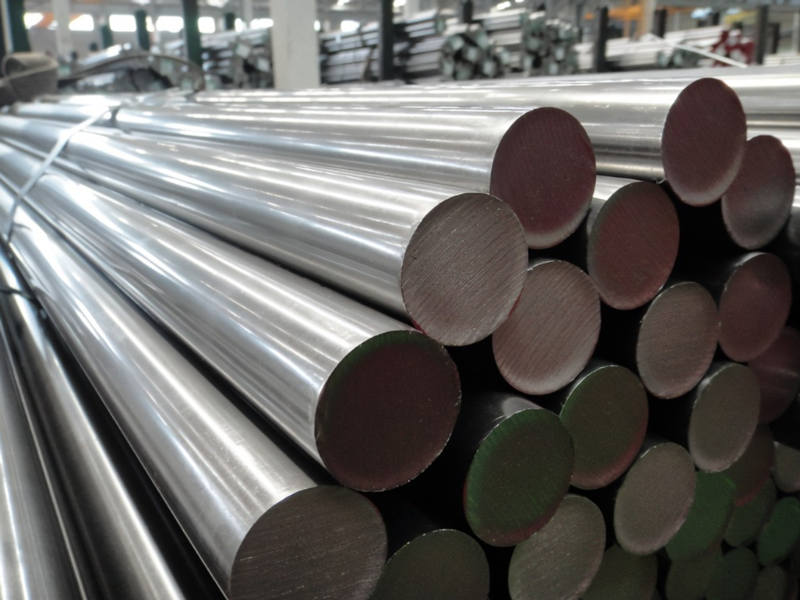

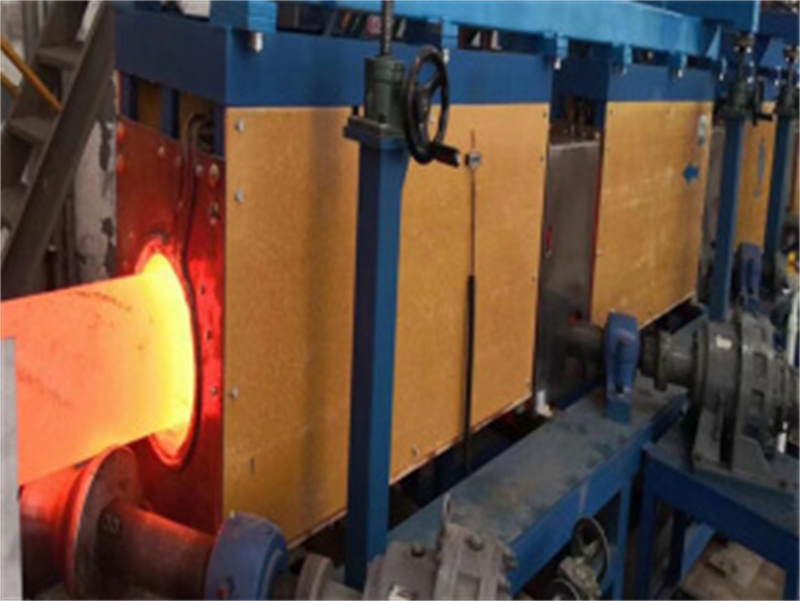

AISI 4130 steel bars are crafted from high-strength, low-alloy steel, primarily employed in high-temperature, high-pressure, and high-strength industrial applications. This chromium-molybdenum low-alloy steel offers significantly higher strength and toughness than standard steel grades. Furthermore, the reduced carbon content of this alloy, while limiting strength through thickness, enhances its weldability compared to its 4140 steel counterpart. These properties render AISI 4130 steel bars a popular choice in the aerospace industry for manufacturing commercial and military aircraft components that demand high strength and low weight.

Product Parameters

| Product Name | AISI/SAE 4130 Alloy Steel Bar | |||

| Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. | |||

| Common Round Bar Specifications | 3.0-50.8 mm, Over 50.8-300mm | |||

| Flat Steel Common Specifications | 6.35x12.7mm, 6.35x25.4mm, 12.7x25.4mm | |||

| Hexagon Bar Common Specifications | AF5.8mm-17mm | |||

| Square Bar Common Specifications | AF2mm-14mm, AF6.35mm, 9.5mm, 12.7mm, 15.98mm, 19.0mm, 25.4mm | |||

| Length | 1-6meters, Size Accept Custom | |||

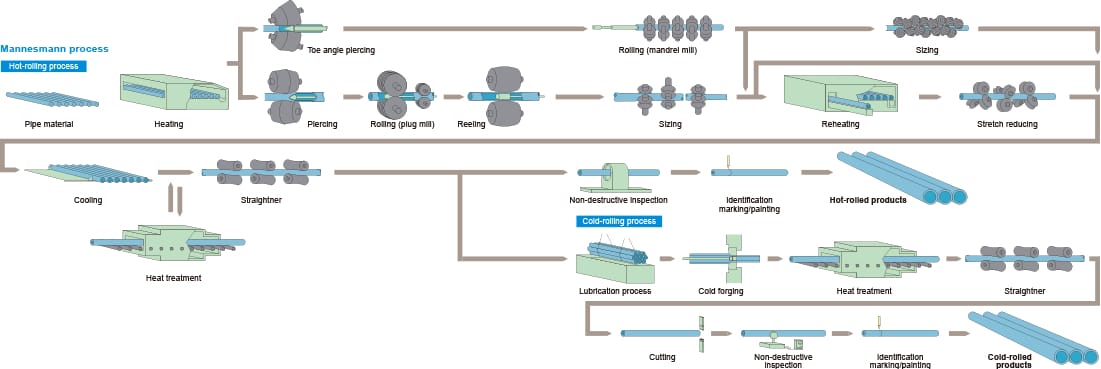

| Diameter(mm) | Hot Rolling Round Bar | 25-600 | Cold Rolling Square Bar |

6-50.8 |

| Hot Rolling Square Bar |

21-54 |

Cold Rolling Hexagon Bar |

9.5-65 |

|

| Cold Rolling Round bar | 6-101.6 | Forged Rebar |

200-1000 |

|

| Surface Process | Bright, Polished, Black | |||

| Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |||

| Scope of Application | SAE 4130 round bars are frequently utilized in structural applications, such as brackets, gears, and certain aircraft exteriors. | |||

Chemical Composition

|

Grade |

Mn |

S |

C |

P |

Si |

Cr |

Mo |

|

AISI 4130 |

0.4-0.8 |

0.04 |

0.28-0.33 |

0.035 |

0.15-0.35 |

0.8-1.1 |

0.15-0.25 |

Mechanical Properties

|

Grade |

Tensile Strength N/mm2 Min |

Yield Strength N/mm2 Min |

A,% Min |

Z,% Min |

|

AISI 4130 |

930 |

735 |

12 |

50 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners