Wear Resistant AISI/SAE 4140 Alloy Steel Bar

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

AISI/SAE 4140 Alloy Steel Bar Description

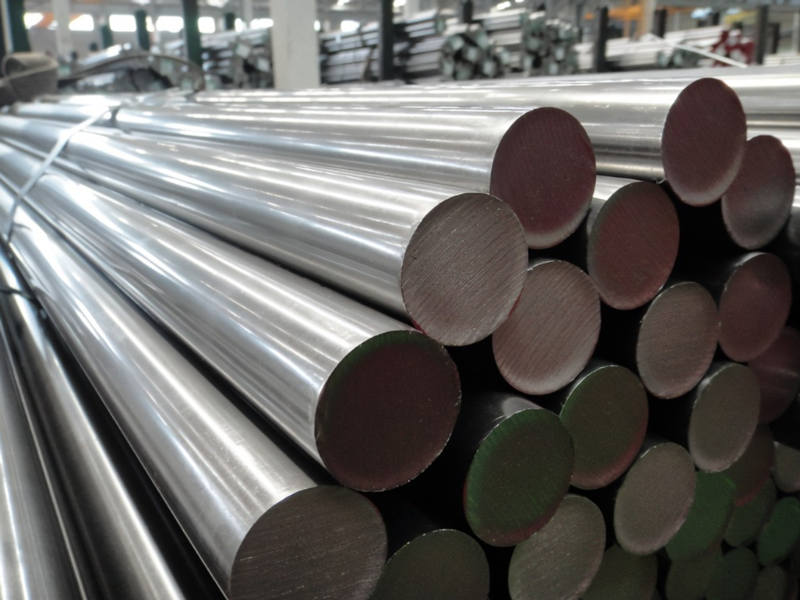

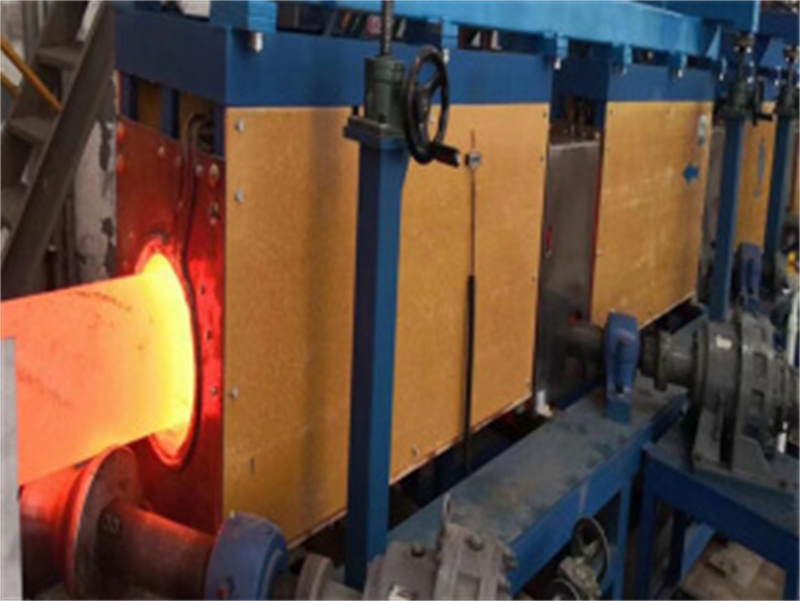

AISI 4140 steel is a 1% chromium-molybdenum general-purpose high-strength steel, typically hardened and tempered within the tensile range of 850-1000 Mpa. It offers enhanced machinability, significantly increasing feed and speed while extending tool life without compromising mechanical properties. Pre-hardened and tempered 4140 steel can undergo further case hardening through flame or induction hardening and nitriding. AISI 4140 steel bars are characterized by high strength, hardenability, good toughness, minimal deformation during quenching, and robust creep strength and enduring strength at elevated temperatures.

Product Parameters

| Product Name | AISI/SAE 4140 Alloy Steel Bar | |||

| Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. | |||

| Common Round Bar Specifications | 3.0-50.8 mm, Over 50.8-300mm | |||

| Flat Steel Common Specifications | 6.35x12.7mm, 6.35x25.4mm, 12.7x25.4mm | |||

| Hexagon Bar Common Specifications | AF5.8mm-17mm | |||

| Square Bar Common Specifications | AF2mm-14mm, AF6.35mm, 9.5mm, 12.7mm, 15.98mm, 19.0mm, 25.4mm | |||

| Length | 1-6meters, Size Accept Custom | |||

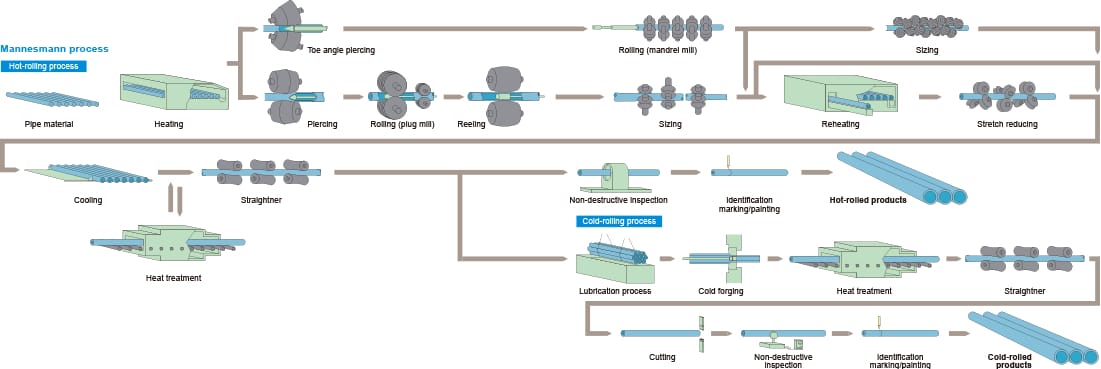

| Diameter(mm) | Hot Rolling Round Bar | 25-600 | Cold Rolling Square Bar |

6-50.8 |

| Hot Rolling Square Bar |

21-54 |

Cold Rolling Hexagon Bar |

9.5-65 |

|

| Cold Rolling Round bar | 6-101.6 | Forged Rebar |

200-1000 |

|

| Surface Process | Bright, Polished, Black | |||

| Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |||

| Scope of Application | SAE 4140 steel is extensively utilized across various industrial sectors, with a broad spectrum of applications including adapters, spindles, axles, bolts, crankshafts, connecting rods, chuck bodies, chucks, conveyor belt pins and rollers, ejection pins, forks, gears, guide rods, hydraulic shafts and parts, lathe spindles, logging parts, milling spindles, motor shafts, nuts, clamping rods, various pins, pump shafts, plungers, sleeves, spindles, sprockets, stud bolts, tool holders, torsion bars, worms, and more. | |||

Chemical Composition

|

Grade |

Mn |

S |

C |

P |

Si |

Cr |

Ni |

|

AISI 4140 |

0.75-1.00 |

0.035 |

0.38-0.43 |

0.035 |

0.20-0.35 |

0.8-1.1 |

0.15-0.25 |

Mechanical Properties

|

Grade |

Tensile Strength psi |

Yield Strength psi |

Elongation % |

Hardness HRC |

|

AISI 4140 |

100k |

80k |

20 |

18-22 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners