World Class 304L Stainless Steel Pipe

- Wechat:18365798883

- WhatsApp:+86-18365798883

- E-Mali:admin@sdxyy.cn

304L Stainless Steel Pipe Description

304L stainless steel pipe is a variation of 304 stainless steel pipe with a lower carbon content, often employed in welding applications. The reduced carbon content significantly diminishes the precipitation of carbides in the heat-affected zone near the weld, which is associated with intergranular corrosion of stainless steel in specific environments. Notably, the annealing of weld joints prior to using the completed metal form is unnecessary with 304L, saving time and effort. In general, both 304 and 304L stainless steel plates can be utilized for many of the same applications, with differences often not significant enough to favor one over the other. 304L stainless steel plate is more commonly used in fields such as food processing equipment, building materials, and automobile parts.

Product Parameters

| Product Name | 304L Stainless Steel Pipe | |

| Type | Steel Pipe | |

| Outer diameter | Round Tube | 4mm-200mm |

| Square Tube | 10*10mm-100*100mm | |

| Rectangular Tube | 10*20mm-50*100mm | |

| Wall Thickness | 0.6mm-6.0mm | |

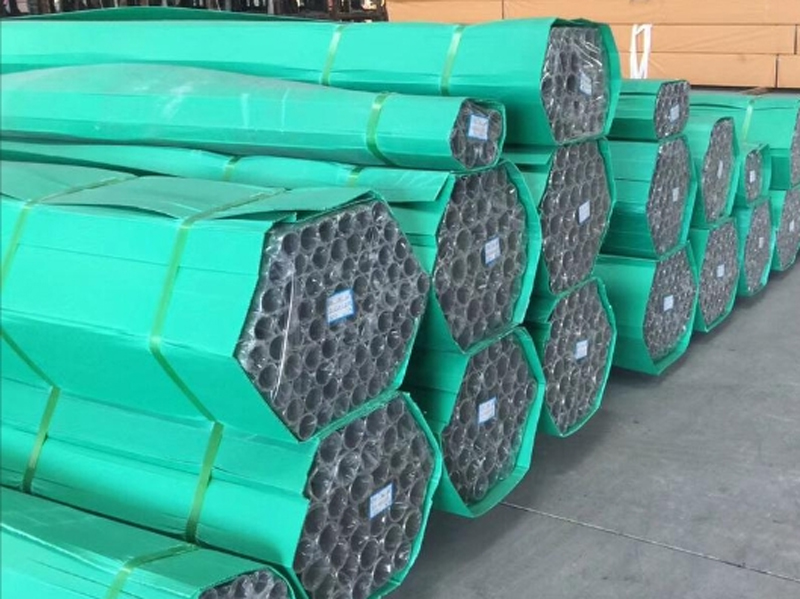

| Length | 1-6 meters, Length can be customized | |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

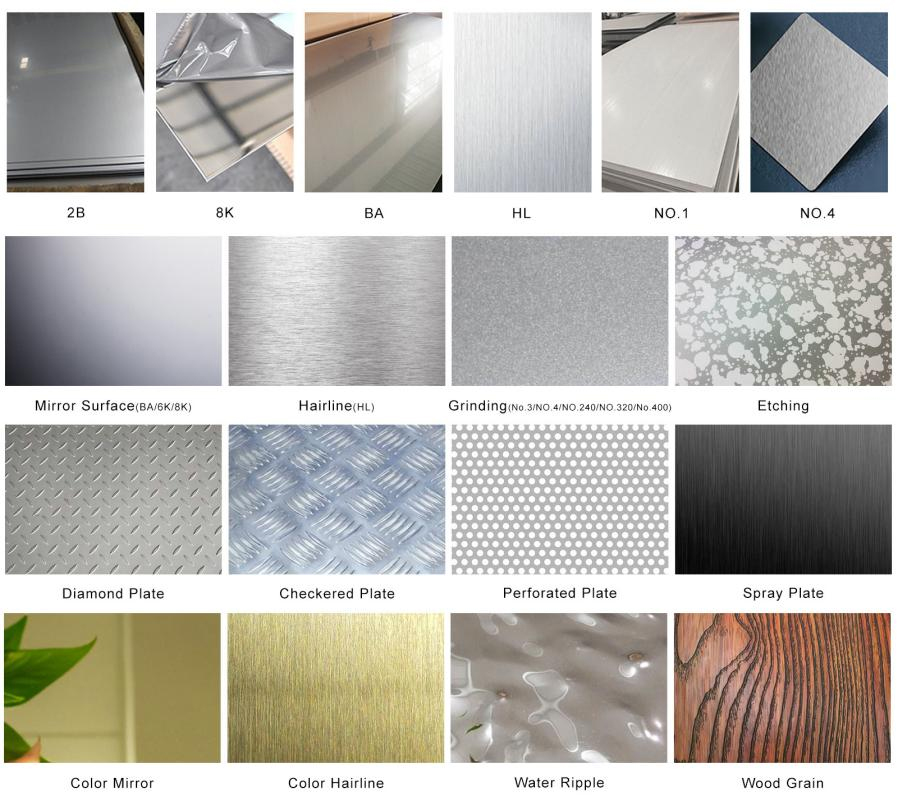

| Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. | |

| Scope of Application | Stainless steel pipes find widespread use across various industries, including food processing, textile operations, breweries, water treatment plants, oil and gas processing, fertilizers and pesticides production, chemical applications, construction, pharmaceuticals, and auto parts manufacturing, among others. | |

| Certificate | ISO, SGS, BV, etc. | |

| Production Technology | Hot Rolling, Cold Rolling | |

| Edge Processing | Edging, Trimming | |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.03 | ≤1.0 | ≤ 2.0 | 18.0~20.0 | 8.0~12.0 | ≤ 0.03 | ≤ 0.035 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥ 520 | ≥ 205 | ≥ 40 | ≤ 187HB ;≤ 90HRB;≤ 200HV |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 8.03 | 193 | 16.9 | 16.2 | 72 |

Angle Steel

Angle Steel Channel Steel

Channel Steel Universal Beam (l-Beam)

Universal Beam (l-Beam) H-Beam Steel

H-Beam Steel Galvalume Steel Coil

Galvalume Steel Coil Galvalume Steel Sheet

Galvalume Steel Sheet Galvanized Steel Sheet

Galvanized Steel Sheet Color Coated Plate

Color Coated Plate Stainless Steel Bar

Stainless Steel Bar Stainless Steel Pipe

Stainless Steel Pipe Steel Bar

Steel Bar Wire Rope

Wire Rope Carbon Steel Pipe

Carbon Steel Pipe Carbon Steel Plate

Carbon Steel Plate Aluminum Plate

Aluminum Plate Aluminum Coil

Aluminum Coil Aluminum Pipe

Aluminum Pipe Aluminum Bar

Aluminum Bar Magnesium Ingot

Magnesium Ingot Fasteners

Fasteners